Difference between revisions of "User:Shawndouglas/sandbox/sublevel12"

Shawndouglas (talk | contribs) (Replaced content with "<div class="nonumtoc">__TOC__</div> {{ombox | type = notice | style = width: 960px; | text = This is sublevel12 of my sandbox, where I play with features and...") Tags: Manual revert Replaced |

Shawndouglas (talk | contribs) (Saving and adding more.) Tag: Reverted |

||

| Line 8: | Line 8: | ||

==Sandbox begins below== | ==Sandbox begins below== | ||

<div class="nonumtoc">__TOC__</div> | <div class="nonumtoc">__TOC__</div> | ||

'''Title''': ''Laboratory Informatics: Information and Workflows'' | |||

'''Author for citation''': Joe Liscouski | |||

'''License for content''': [https://creativecommons.org/licenses/by-sa/4.0/ Creative Commons Attribution-ShareAlike 4.0 International] | |||

'''Publication date''': April 2024 | |||

'''NOTE''': This content originally appeared in Liscouski's ''Computerized Systems in the Modern Laboratory: A Practical Guide'' as Chapter 3 - Laboratory Informatics / Departmental Systems, published in 2015 by PDA/DHI, ISBN 193372286X. This is reproduced here with the author's / copyright holder's permission. Some changes have been made to the original material, replacing some out-of-date screen shots with vendor-neutral mock-ups, for example. In addition, note that some specifications for network speeds are out-of-date but the concerns with system performance are still realistic. | |||

==Introduction== | |||

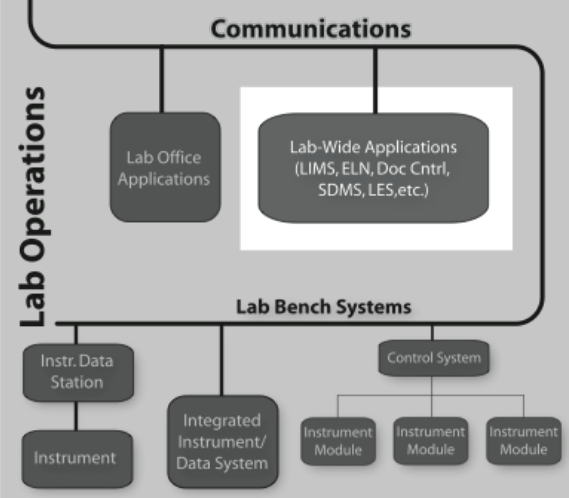

[[Laboratory informatics]] refers to software systems that usually are accessible at the departmental level–they are often shared between users in the [[Laboratory|lab]]-and focus on managing lab operations, and lab-wide [[information]] rather than instrument management or [[Sample (material)|sample]] preparation (Figure 3-1). | |||

[[File:Fig3-1 Liscouski LabInfo24.png|500px]] | |||

{{clear}} | |||

{| | |||

| style="vertical-align:top;" | | |||

{| border="0" cellpadding="5" cellspacing="0" width="500px" | |||

|- | |||

| style="background-color:white; padding-left:10px; padding-right:10px;" |<blockquote>'''Figure 3-1.''' Laboratory informatics and departmental systems.</blockquote> | |||

|- | |||

|} | |||

|} | |||

Differing from standard office applications (e.g., word processing, spreadsheets, etc.), laboratory informatics software solutions include the: | |||

* [[laboratory information management system]] (LIMS) and [[laboratory information system]] (LIS) | |||

* [[electronic laboratory notebook]] (ELN) | |||

* [[document management system]] (DMS) | |||

* [[scientific data management system]] (SDMS) | |||

* [[laboratory execution system]] (LES), and | |||

* [[Inventory management|chemical inventory management]] (CIM). | |||

Before we get into the details of what these technologies are, we must establish a framework for understanding laboratory operations so that we can see where products fit in the lab's [[workflow]]. The products you introduce into your lab are going to depend on the lab's needs, and given the complexity of vendor offerings and their potential interactions and overlapping capabilities, defining your requirements is going to take some thought. | |||

These products are undergoing a rapid evolution driven by market pressures as vendors compete for your business, partly by trying to cover as much of a lab’s operations as they can. If you look at functional checkboxes in brochures, they often cover similar elements, but their strengths, weaknesses, and methods of operation are different, and those differences should be important to you. | |||

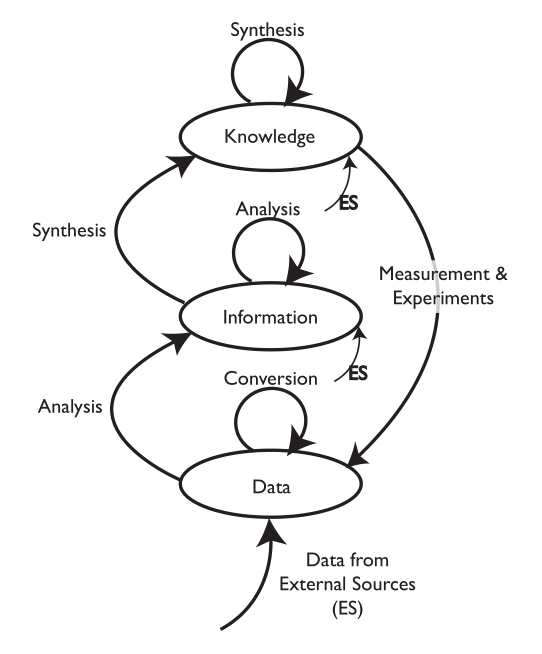

We are going to start by comparing two different types of laboratory environments: [[research]] labs and service labs (laboratories whose role is to provide testing, and assays, for example, [[quality control]], clinical labs, etc.). That comparison and subsequent material is going to be done with the aid of an initially simple model for the development and flow of knowledge, information, and data within laboratories (Figure 3-2). | |||

[[File:Fig1 Liscouski DirectLabSysOnePerPersp21.png|400px]] | |||

{{clear}} | |||

{| | |||

| style="vertical-align:top;" | | |||

{| border="0" cellpadding="5" cellspacing="0" width="400px" | |||

|- | |||

| style="background-color:white; padding-left:10px; padding-right:10px;" |<blockquote>'''Figure 3-2.''' Basic K/I/D model. Databases for knowledge, information, and data (K/I/D) are represented as ovals, and the processes acting on them as arrows.</blockquote> | |||

|- | |||

|} | |||

|} | |||

The model consists of ovals and arrows; the ovals represent collections of files and databases supporting applications, and the arrows are processes for working with the materials in those collections. The “ES” abbreviation notes processes that bring in elements from sources outside the lab. The first point we need to address is the definition of “knowledge,” “information,” and “data,” as used here. We are not talking about philosophical points, but how these are represented and used in the digital world. “Knowledge” is usually reports, documents, etc. that may exist as individual files or be organized and accessed through applications software. That software would include DMSs, databases for working with hazardous materials, reference databases, and access to published material stored locally or accessed over internal/external networks. | |||

“Information” consists of elements that can be understood by themselves such as [[pH Meter|pH measurements]], the results of an analysis, an object's temperature, an infrared spectrum, the name of a file, and so on. Information elements can reside as fields in databases and files. Information can be provided as meaningful answers to questions. Finally, “Data” refers to measurements that by themselves may not have any meaning, or that require conversion or be combined with other data and analyzed before they are useful information. For example, the twenty-seventh value in a digital [[Chromatography|chromatogram]] data stream, the area of a peak (needs comparison to known quantities before it is useful), millivolt readings from a pH meter (you need temperature information and other elements before you can convert it to pH), etc. | |||

There are grey areas and examples where these definitions may not hold up well, but the key point is how they are obtained, stored, and used. You may want to modify the definitions to suit your work, but the comments above are how they are used here. | |||

The arrows represent processes that operate on material in one storage structure and put the results of the work in another. Processes will consist of one or more steps or stages and can include work done in the lab as well as outside the lab (outsourced processing, access to networked systems, for example). It is possible that operations will be performed on material in one storage structure and have those results placed in the same storage level. For example, several “information” elements may be processed to create a new information entity. | |||

Initially, we are going to discuss the model as a two-dimensional structure, but those storage systems and processes have layers of software, hardware, and networked communications. In addition, the diagram as shown is a simplification of reality since it shows only one process for an experiment. In the real world, there would be a process line for each laboratory process in your lab, and the “data” oval would represent a collection of data storage elements from each of the data acquisition/storage/analysis systems in the lab. Each experimental process would have a link to the “knowledge” structures catalog of standard operating procedures (SOPs). As we start to build on this structure we can see how requirements for products and workflow can be derived. | |||

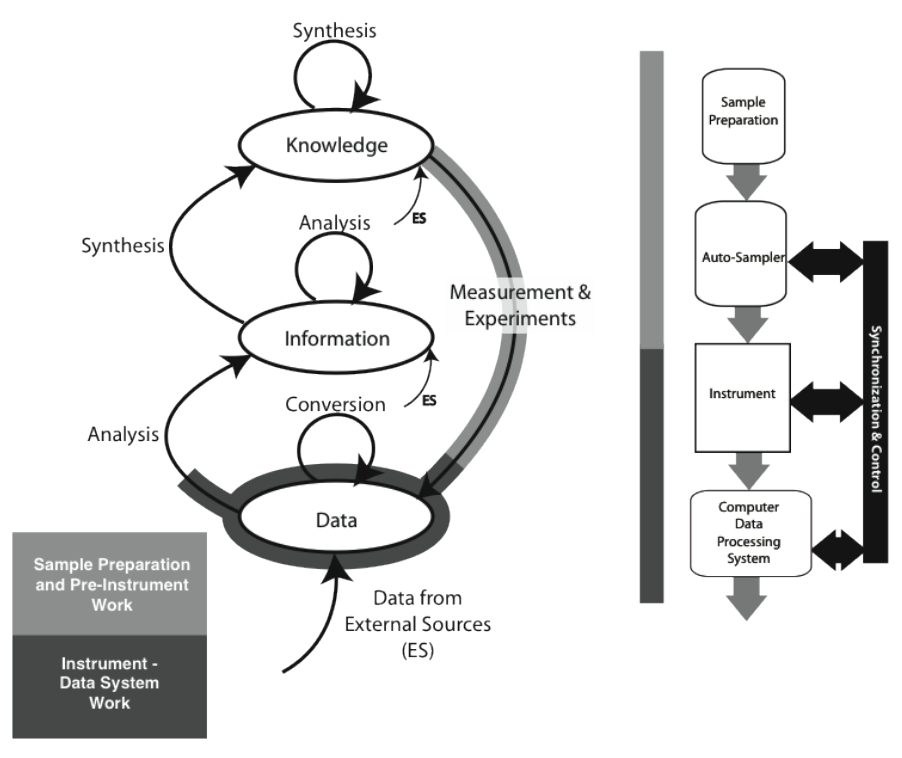

The material covered in the Lab Bench chapter (Chapter 1) fits the model as shown in Figure 3-3 (the model used in the Lab Bench discussion is shown as well; it is represented by the light-/heavy-grey lines in the K/I/D model). The sample preparation and pre-instrumental analysis work is shown as the light-grey / heavy-line portion of the “Measurement & Experiments” process, with instrumental data acquisition, storage, and analysis displayed with the darker grey/heavy line (which may be entirely or partly completed by the software; the illustration shows the “partial” case). Not all experiment/instrument interactions result in the use of a storage system. Balances, for example, may hold one reading and then send it through to the information storage on command, where it may be analyzed with other information. The procedure description needed to execute a laboratory process—the measurement and experiment—would come from material in the “Knowledge” storage structure. | |||

[[File:Fig3-3 Liscouski LabInfo24.png|800px]] | |||

{{clear}} | |||

{| | |||

| style="vertical-align:top;" | | |||

{| border="0" cellpadding="5" cellspacing="0" width="800px" | |||

|- | |||

| style="background-color:white; padding-left:10px; padding-right:10px;" |<blockquote>'''Figure 3-3.''' The K/I/D model showing areas covered by the Lab Bench chapter.</blockquote> | |||

|- | |||

|} | |||

|} | |||

What we are concerned about in laboratory informatics is what happens to the data and information that results either from data analysis or information gained directly from experiments. | |||

==Comparing two different laboratory operational environments== | |||

==About the author== | |||

Initially educated as a chemist, author Joe Liscouski (joe dot liscouski at gmail dot com) is an experienced laboratory automation/computing professional with over forty years of experience in the field, including the design and development of automation systems (both custom and commercial systems), LIMS, robotics and data interchange standards. He also consults on the use of computing in laboratory work. He has held symposia on validation and presented technical material and short courses on laboratory automation and computing in the U.S., Europe, and Japan. He has worked/consulted in pharmaceutical, biotech, polymer, medical, and government laboratories. His current work centers on working with companies to establish planning programs for lab systems, developing effective support groups, and helping people with the application of automation and information technologies in research and quality control environments. | |||

==References== | |||

{{Reflist|colwidth=30em}} | |||

<!---Place all category tags here--> | |||

Revision as of 15:59, 5 April 2024

|

|

This is sublevel12 of my sandbox, where I play with features and test MediaWiki code. If you wish to leave a comment for me, please see my discussion page instead. |

Sandbox begins below

Title: Laboratory Informatics: Information and Workflows

Author for citation: Joe Liscouski

License for content: Creative Commons Attribution-ShareAlike 4.0 International

Publication date: April 2024

NOTE: This content originally appeared in Liscouski's Computerized Systems in the Modern Laboratory: A Practical Guide as Chapter 3 - Laboratory Informatics / Departmental Systems, published in 2015 by PDA/DHI, ISBN 193372286X. This is reproduced here with the author's / copyright holder's permission. Some changes have been made to the original material, replacing some out-of-date screen shots with vendor-neutral mock-ups, for example. In addition, note that some specifications for network speeds are out-of-date but the concerns with system performance are still realistic.

Introduction

Laboratory informatics refers to software systems that usually are accessible at the departmental level–they are often shared between users in the lab-and focus on managing lab operations, and lab-wide information rather than instrument management or sample preparation (Figure 3-1).

|

Differing from standard office applications (e.g., word processing, spreadsheets, etc.), laboratory informatics software solutions include the:

- laboratory information management system (LIMS) and laboratory information system (LIS)

- electronic laboratory notebook (ELN)

- document management system (DMS)

- scientific data management system (SDMS)

- laboratory execution system (LES), and

- chemical inventory management (CIM).

Before we get into the details of what these technologies are, we must establish a framework for understanding laboratory operations so that we can see where products fit in the lab's workflow. The products you introduce into your lab are going to depend on the lab's needs, and given the complexity of vendor offerings and their potential interactions and overlapping capabilities, defining your requirements is going to take some thought.

These products are undergoing a rapid evolution driven by market pressures as vendors compete for your business, partly by trying to cover as much of a lab’s operations as they can. If you look at functional checkboxes in brochures, they often cover similar elements, but their strengths, weaknesses, and methods of operation are different, and those differences should be important to you.

We are going to start by comparing two different types of laboratory environments: research labs and service labs (laboratories whose role is to provide testing, and assays, for example, quality control, clinical labs, etc.). That comparison and subsequent material is going to be done with the aid of an initially simple model for the development and flow of knowledge, information, and data within laboratories (Figure 3-2).

|

The model consists of ovals and arrows; the ovals represent collections of files and databases supporting applications, and the arrows are processes for working with the materials in those collections. The “ES” abbreviation notes processes that bring in elements from sources outside the lab. The first point we need to address is the definition of “knowledge,” “information,” and “data,” as used here. We are not talking about philosophical points, but how these are represented and used in the digital world. “Knowledge” is usually reports, documents, etc. that may exist as individual files or be organized and accessed through applications software. That software would include DMSs, databases for working with hazardous materials, reference databases, and access to published material stored locally or accessed over internal/external networks.

“Information” consists of elements that can be understood by themselves such as pH measurements, the results of an analysis, an object's temperature, an infrared spectrum, the name of a file, and so on. Information elements can reside as fields in databases and files. Information can be provided as meaningful answers to questions. Finally, “Data” refers to measurements that by themselves may not have any meaning, or that require conversion or be combined with other data and analyzed before they are useful information. For example, the twenty-seventh value in a digital chromatogram data stream, the area of a peak (needs comparison to known quantities before it is useful), millivolt readings from a pH meter (you need temperature information and other elements before you can convert it to pH), etc.

There are grey areas and examples where these definitions may not hold up well, but the key point is how they are obtained, stored, and used. You may want to modify the definitions to suit your work, but the comments above are how they are used here.

The arrows represent processes that operate on material in one storage structure and put the results of the work in another. Processes will consist of one or more steps or stages and can include work done in the lab as well as outside the lab (outsourced processing, access to networked systems, for example). It is possible that operations will be performed on material in one storage structure and have those results placed in the same storage level. For example, several “information” elements may be processed to create a new information entity.

Initially, we are going to discuss the model as a two-dimensional structure, but those storage systems and processes have layers of software, hardware, and networked communications. In addition, the diagram as shown is a simplification of reality since it shows only one process for an experiment. In the real world, there would be a process line for each laboratory process in your lab, and the “data” oval would represent a collection of data storage elements from each of the data acquisition/storage/analysis systems in the lab. Each experimental process would have a link to the “knowledge” structures catalog of standard operating procedures (SOPs). As we start to build on this structure we can see how requirements for products and workflow can be derived.

The material covered in the Lab Bench chapter (Chapter 1) fits the model as shown in Figure 3-3 (the model used in the Lab Bench discussion is shown as well; it is represented by the light-/heavy-grey lines in the K/I/D model). The sample preparation and pre-instrumental analysis work is shown as the light-grey / heavy-line portion of the “Measurement & Experiments” process, with instrumental data acquisition, storage, and analysis displayed with the darker grey/heavy line (which may be entirely or partly completed by the software; the illustration shows the “partial” case). Not all experiment/instrument interactions result in the use of a storage system. Balances, for example, may hold one reading and then send it through to the information storage on command, where it may be analyzed with other information. The procedure description needed to execute a laboratory process—the measurement and experiment—would come from material in the “Knowledge” storage structure.

|

What we are concerned about in laboratory informatics is what happens to the data and information that results either from data analysis or information gained directly from experiments.

Comparing two different laboratory operational environments

About the author

Initially educated as a chemist, author Joe Liscouski (joe dot liscouski at gmail dot com) is an experienced laboratory automation/computing professional with over forty years of experience in the field, including the design and development of automation systems (both custom and commercial systems), LIMS, robotics and data interchange standards. He also consults on the use of computing in laboratory work. He has held symposia on validation and presented technical material and short courses on laboratory automation and computing in the U.S., Europe, and Japan. He has worked/consulted in pharmaceutical, biotech, polymer, medical, and government laboratories. His current work centers on working with companies to establish planning programs for lab systems, developing effective support groups, and helping people with the application of automation and information technologies in research and quality control environments.

References