Difference between revisions of "User:Shawndouglas/sandbox/sublevel10"

Shawndouglas (talk | contribs) |

Shawndouglas (talk | contribs) |

||

| Line 205: | Line 205: | ||

====2.2.3 Pharmaceutical and medical devices==== | ====2.2.3 Pharmaceutical and medical devices==== | ||

'''2.2.3.x Current Good Manufacturing Practice (CGMP) regulations - ''United States''''' | '''2.2.3.x Current Good Manufacturing Practice (CGMP) regulations - ''United States and other countries''''' | ||

For more on this, see the next subsection on other industries and regulations. | For more on this, see the next subsection on other industries and regulations. | ||

| Line 211: | Line 211: | ||

====2.3.4 Other industries and regulations==== | ====2.3.4 Other industries and regulations==== | ||

'''2.3.4.x Good manufacturing practice (GMP) and current good manufacturing practice (cGMP)''' | |||

'''2.3.4.x Good manufacturing practice (GMP) and current good manufacturing practice (cGMP) - ''United States and other countries''''' | |||

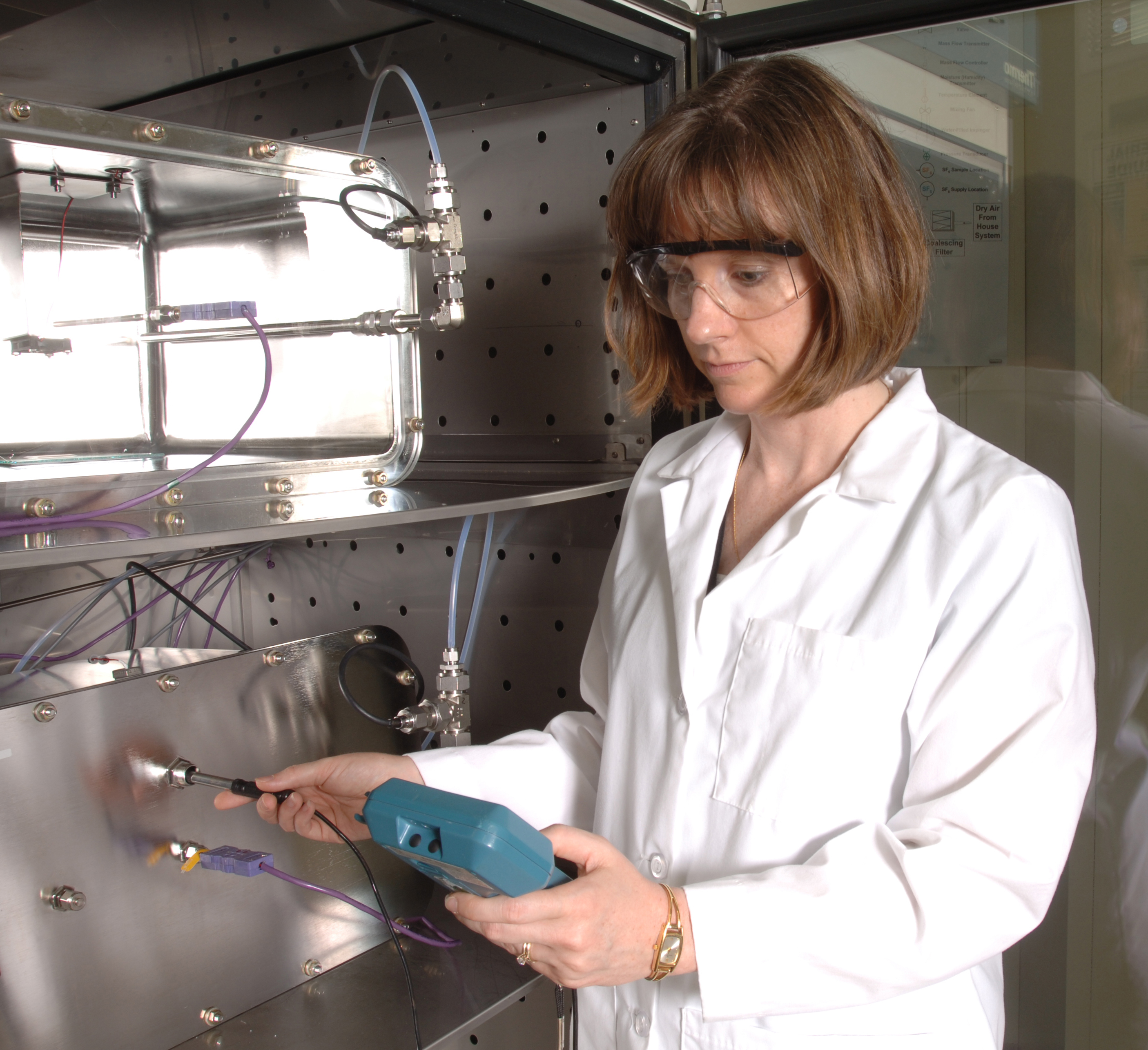

As a broad concept, [[good manufacturing practice]] or GMP is an organized set of standards and guidelines that allow manufacturers of most any product to better ensure their products are consistently produced and packaged to a consistent level of quality. GMP tends to cover most every step of production, from planning recipes and choosing starting materials to training personnel and documenting processes.<ref name="ISPEGMP">{{cite web |url=https://ispe.org/initiatives/regulatory-resources/gmp |title=Good Manufacturing Practice (GMP) Resources |publisher=International Society for Pharmaceutical Engineering, Inc |accessdate=21 April 2023}}</ref> The concept of GMP is often spoken of in terms of pharmaceutical and medical device manufacturing<ref name="ISPEGMP" /><ref name="WHOMedicines15">{{cite web |url=https://www.who.int/news-room/questions-and-answers/item/medicines-good-manufacturing-processes |title=Medicines: Good manufacturing practices |publisher=World Health Organization |date=20 November 2015 |accessdate=21 April 2023}}</ref>, though it is applicable to most any other production industry.<ref name="CEReg07">{{cite web |url=https://www.controleng.com/articles/regulated-or-not-know-good-manufacturing-practices-gmp/ |title=Regulated or not? Know good manufacturing practices (GMP) |author=''Control Engineering'' Staff |work=Control Engineering |date=14 July 2007 |accessdate=21 April 2023}}</ref><ref name="FDAGMPCosm22">{{cite web |url=https://www.fda.gov/cosmetics/cosmetics-guidance-documents/good-manufacturing-practice-gmp-guidelinesinspection-checklist-cosmetics |title=Good Manufacturing Practice (GMP) Guidelines/Inspection Checklist for Cosmetics |publisher=U.S. Food and Drug Administration |date=25 February 2022 |accessdate=21 April 2023}}</ref> | As a broad concept, [[good manufacturing practice]] or GMP is an organized set of standards and guidelines that allow manufacturers of most any product to better ensure their products are consistently produced and packaged to a consistent level of quality. GMP tends to cover most every step of production, from planning recipes and choosing starting materials to training personnel and documenting processes.<ref name="ISPEGMP">{{cite web |url=https://ispe.org/initiatives/regulatory-resources/gmp |title=Good Manufacturing Practice (GMP) Resources |publisher=International Society for Pharmaceutical Engineering, Inc |accessdate=21 April 2023}}</ref> The concept of GMP is often spoken of in terms of pharmaceutical and medical device manufacturing<ref name="ISPEGMP" /><ref name="WHOMedicines15">{{cite web |url=https://www.who.int/news-room/questions-and-answers/item/medicines-good-manufacturing-processes |title=Medicines: Good manufacturing practices |publisher=World Health Organization |date=20 November 2015 |accessdate=21 April 2023}}</ref>, though it is applicable to most any other production industry.<ref name="CEReg07">{{cite web |url=https://www.controleng.com/articles/regulated-or-not-know-good-manufacturing-practices-gmp/ |title=Regulated or not? Know good manufacturing practices (GMP) |author=''Control Engineering'' Staff |work=Control Engineering |date=14 July 2007 |accessdate=21 April 2023}}</ref><ref name="FDAGMPCosm22">{{cite web |url=https://www.fda.gov/cosmetics/cosmetics-guidance-documents/good-manufacturing-practice-gmp-guidelinesinspection-checklist-cosmetics |title=Good Manufacturing Practice (GMP) Guidelines/Inspection Checklist for Cosmetics |publisher=U.S. Food and Drug Administration |date=25 February 2022 |accessdate=21 April 2023}}</ref> | ||

| Line 221: | Line 220: | ||

Closely related is the term "current good manufacturing practice" or cGMP. Both "GMP" and "cGMP" are largely interchangeable, though the latter is preferred in most regulatory language of the United States. A more nuanced take says that cGMP essentially represents the newest, most updated technologies implemented towards the goals of meeting GMP requirements.<ref name="PSDiff21">{{cite web |url=https://www.pharmaspecialists.com/2021/10/difference-between-gmp-and-cgmp.html#gsc.tab=0 |title=Difference Between GMP and cGMP |work=Pharma Specialists |date=13 October 2021 |accessdate=21 April 2023}}</ref><ref name="MoravekTheDiff">{{cite web |url=https://www.moravek.com/the-differences-between-gmp-and-cgmp/ |title=The Differences Between GMP and cGMP |work=Moravek Blog |publisher=Moravek, Inc |date=January 2021 |accessdate=21 April 2023}}</ref> | Closely related is the term "current good manufacturing practice" or cGMP. Both "GMP" and "cGMP" are largely interchangeable, though the latter is preferred in most regulatory language of the United States. A more nuanced take says that cGMP essentially represents the newest, most updated technologies implemented towards the goals of meeting GMP requirements.<ref name="PSDiff21">{{cite web |url=https://www.pharmaspecialists.com/2021/10/difference-between-gmp-and-cgmp.html#gsc.tab=0 |title=Difference Between GMP and cGMP |work=Pharma Specialists |date=13 October 2021 |accessdate=21 April 2023}}</ref><ref name="MoravekTheDiff">{{cite web |url=https://www.moravek.com/the-differences-between-gmp-and-cgmp/ |title=The Differences Between GMP and cGMP |work=Moravek Blog |publisher=Moravek, Inc |date=January 2021 |accessdate=21 April 2023}}</ref> | ||

In the United States, cGMP—in the context of pharmaceuticals—is enshrined in numerous sections of Title 21 of the Code of Federal Regulations, including "in parts 1-99, 200-299, 300-499, 600-799, and 800-1299."<ref name="FDAcGMP22">{{cite web |url=https://www.fda.gov/drugs/pharmaceutical-quality-resources/current-good-manufacturing-practice-cgmp-regulations |title=Current Good Manufacturing Practice (CGMP) Regulations |author=U.S. Food and Drug Administration |date=16 November 2022 |accessdate=26 April 2023}}</ref> The FDA describes these regulations as containing "minimum requirements for the methods, facilities, and controls used in manufacturing, processing, and packing of a drug product."<ref name="FDAcGMP22" /> It also states safety, efficacy, and labeling requirements for manufactured drugs. | In the United States, cGMP—in the context of pharmaceuticals—is enshrined in numerous sections of Title 21 of the Code of Federal Regulations, including "in parts 1-99, 200-299, 300-499, 600-799, and 800-1299."<ref name="FDAcGMP22">{{cite web |url=https://www.fda.gov/drugs/pharmaceutical-quality-resources/current-good-manufacturing-practice-cgmp-regulations |title=Current Good Manufacturing Practice (CGMP) Regulations |author=U.S. Food and Drug Administration |date=16 November 2022 |accessdate=26 April 2023}}</ref> The FDA describes these regulations as containing "minimum requirements for the methods, facilities, and controls used in manufacturing, processing, and packing of a drug product."<ref name="FDAcGMP22" /> It also states safety, efficacy, and labeling requirements for manufactured drugs. These regulations require careful attention by manufacturers, lest they face seizure of their products, legal injunction, and criminal cases.<ref name="FDAFactsAb21">{{cite web |url=https://www.fda.gov/drugs/pharmaceutical-quality-resources/facts-about-current-good-manufacturing-practices-cgmps |title=Facts About the Current Good Manufacturing Practices (cGMPs) |author=U.S. Food and Drug Administration |date=01 June 2021 |accessdate=26 April 2023}}</ref> | ||

In the context of food, cGMP principles were first introduced in the U.S. in 1969 as 21 CFR Part 110, though the concept of cGMP was modernized in 2015, in 21 CFR Part 117. This led to not only broad food- and beverage-based cGMPs but also cGMPs specific to a type of ingestible, including dietary supplements, infant formula, low-acid canned food, and bottled water.<ref name="FDACurrentGood20">{{cite web |url=https://www.fda.gov/food/guidance-regulation-food-and-dietary-supplements/current-good-manufacturing-practices-cgmps-food-and-dietary-supplements |title=Current Good Manufacturing Practices (CGMPs) for Food and Dietary Supplements |publisher=U.S. Food and Drug Administration |date=31 January 2020 |accessdate=21 April 2023}}</ref> | In the context of food, cGMP principles were first introduced in the U.S. in 1969 as 21 CFR Part 110, though the concept of cGMP was modernized in 2015, in 21 CFR Part 117. This led to not only broad food- and beverage-based cGMPs but also cGMPs specific to a type of ingestible, including dietary supplements, infant formula, low-acid canned food, and bottled water.<ref name="FDACurrentGood20">{{cite web |url=https://www.fda.gov/food/guidance-regulation-food-and-dietary-supplements/current-good-manufacturing-practices-cgmps-food-and-dietary-supplements |title=Current Good Manufacturing Practices (CGMPs) for Food and Dietary Supplements |publisher=U.S. Food and Drug Administration |date=31 January 2020 |accessdate=21 April 2023}}</ref> | ||

GMP and cGMP contexts also exist for other manufacturing industries outside of pharmaceuticals and food, including automotive parts, medical devices, clothing, and more.<ref name="DomingoTheComp22">{{cite web |url=https://qvalon.com/blog/the-complete-guide-to-good-manufacturing-practices-gmp-by-qvalon/ |title=The Complete Guide to Good Manufacturing Practices (GMP) by QVALON |author=Domingo, J. |publisher=QVALON Inc |date=28 January 2022 |accessdate=21 April 2023}}</ref> Additionally, these concepts are not limited to the U.S. For example, the World Health Organization has its own GMP/cGMP guidelines for pharmaceuticals and biological medicines, with more than 100 countries reportedly incorporating those guidelines into their national medicine regulations.<ref name="WHOGMP18">{{cite web |url=https://www.who.int/teams/health-product-policy-and-standards/standards-and-specifications/gmp |title=Health products policy and standards - Good Manufacturing Practices |publisher=World Health Organization |date=28 September 2018 |accessdate=26 April 2023}}</ref> | GMP and cGMP contexts also exist for other manufacturing industries outside of pharmaceuticals and food, including automotive parts, medical devices, clothing, and more.<ref name="DomingoTheComp22">{{cite web |url=https://qvalon.com/blog/the-complete-guide-to-good-manufacturing-practices-gmp-by-qvalon/ |title=The Complete Guide to Good Manufacturing Practices (GMP) by QVALON |author=Domingo, J. |publisher=QVALON Inc |date=28 January 2022 |accessdate=21 April 2023}}</ref> Additionally, these concepts are not limited to the U.S. For example, the World Health Organization has its own GMP/cGMP guidelines for pharmaceuticals and biological medicines, with more than 100 countries reportedly incorporating those guidelines into their national medicine regulations.<ref name="WHOGMP18">{{cite web |url=https://www.who.int/teams/health-product-policy-and-standards/standards-and-specifications/gmp |title=Health products policy and standards - Good Manufacturing Practices |publisher=World Health Organization |date=28 September 2018 |accessdate=26 April 2023}}</ref> | ||

'''2.3.4.x Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) Regulation - ''European Union''''' | |||

For the E.U. chemical manufacturing and other manufacturing industries depending on those chemicals, REACH represents one of the most expansive and complicated pieces of regulation in the E.U. Affecting potentially more than 140,000 substances, manufacturers of those substances are now largely responsible for identifying hazards, identifying mitigation methods for those hazards, and managing associated risks. Of particular note are "substances of very high concern" (SVHCs) and how they are authorized and restricted. This regulations means manufacturers must pay closer attention to what substances get put into their products and report on SVHCs making up more than 0.1% (by weight) of the product. These regulations may also mean the manufacturer may need to redesign their products with new substances.<ref name="ECIAREACH21">{{cite web |url=https://www.ecianow.org/reach |title=REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) |publisher=Electronic Components Industry Association |date=2021 |accessdate=26 April 2023}}</ref> | |||

'''2.3.4.x Resolução de diretoria colegiada - RDC nº 529 - ''Brazil''''' | '''2.3.4.x Resolução de diretoria colegiada - RDC nº 529 - ''Brazil''''' | ||

This Brazilian resolution, effective August 2021, revised the country's List of Prohibited Substances in Personal Hygiene, Cosmetics and Perfume Products to include additional substances. While it's not clear what original legislation houses that list, this list makes clear that manufacturers of personal hygiene, cosmetic, and perfume products have to be mindful of the ingredients they use in their manufacturing processes.<ref name="HavensBrazil21">{{cite web |url=https://www.ul.com/news/brazil-revises-list-prohibited-substances-cosmetics |title=Brazil Revises List of Prohibited Substances in Cosmetics |author=Havens, R. |work=UL Solutions |date=02 September 2021 |accessdate=26 April 2023}}</ref> | This Brazilian resolution, effective August 2021, revised the country's List of Prohibited Substances in Personal Hygiene, Cosmetics and Perfume Products to include additional substances. While it's not clear what original legislation houses that list, this list makes clear that manufacturers of personal hygiene, cosmetic, and perfume products have to be mindful of the ingredients they use in their manufacturing processes.<ref name="HavensBrazil21">{{cite web |url=https://www.ul.com/news/brazil-revises-list-prohibited-substances-cosmetics |title=Brazil Revises List of Prohibited Substances in Cosmetics |author=Havens, R. |work=UL Solutions |date=02 September 2021 |accessdate=26 April 2023}}</ref> | ||

'''2.3.4.x Restriction of Hazardous Substances in Electrical and Electronic Equipment (RoHS) Directive - ''European Union''''' | |||

The E.U. uses the RoHS Directive as a means towards restricting the use of specific hazardous materials in the manufacture of electrical and electronic equipment (EEE), namely "lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE), bis(2-ethylhexyl) phthalate (DEHP), butyl benzyl phthalate (BBP), dibutyl phthalate (DBP) and diisobutyl phthalate (DIBP)."<ref name="ECRestrict">{{cite web |url=https://environment.ec.europa.eu/topics/waste-and-recycling/rohs-directive_en |title=Restriction of Hazardous Substances in Electrical and Electronic Equipment (RoHS) |publisher=European Commission |date=2023 |accessdate=26 April 2023}}</ref> By extension, the E.U. is encouraging safer alternatives for the manufacturing of EEE and fewer hazardous substances making their way into ecosystems from waste streams. | |||

==References== | ==References== | ||

{{Reflist|colwidth=30em}} | {{Reflist|colwidth=30em}} | ||

Revision as of 23:28, 26 April 2023

|

|

This is sublevel10 of my sandbox, where I play with features and test MediaWiki code. If you wish to leave a comment for me, please see my discussion page instead. |

Sandbox begins below

Societies around the world have grown to expect and depend on high-quality products that prove safe to their health. ...

This chapter will briefly examine the standards, regulations, guidance, and other factors globally driven by not only the demand for safer products, but also that in many cases dictate what and how quality activities are conducted towards ensuring product safety around the world inside and outside the manufacturing-based laboratory.

2.1 Globally recognized manufacturing standards

Manufacturing industries of all types depend on well-defined and -justified standards to better ensure the quality of their products. Implementing and maintaining conformance to internationally recognized and benchmarked safety and quality standards benefits the manufacturer in a number of ways[1][2][3][4]:

- It increases customer confidence through the organization's audited certification to the standard, taking the place of customers' own auditing methods to ensure quality and authenticity, in turn reducing time and costs.

- It drives organizations to better monitor their activities for non-conformities, identify root causes, and develop preventative controls, while clearly reporting such efforts to customers, further reducing the need for customer audits.

- It better ensures a rigorous and comprehensive approach to product safety, quality, integrity, and legality, in many cases meeting or exceeding local, state, federal, and/or international legislative requirements.

- It drives organizations to better vet their suppliers and service providers for meeting required product safety management practices.

- It enables organizations to better demonstrate auditable compliance with modern product safety management practices.

- It allows organizations to limit product recalls, reduce customer complaints, and better protect their brand.

As such, manufacturers adopt standards from one or more organizations around the world, not only to benefit their operations but also meet or exceed regulatory requirements for their industry. What follows are some of the more critical standards and guidelines that apply to a wide variety of manufacturing industries.

2.1.1 Food and beverage

Food and beverage researchers and manufacturers adopt standards from one or more organizations around the world, not only to benefit their operations but also meet or exceed regulatory requirements for their industry. What follows are some of the more critical standards and guidelines that apply to the food, beverage, and feed industries.

2.1.1.1 British Retail Consortium (BRC) Global Standard for Food Safety (GSFS)

In 1998, the British Retail Consortium (BRD) published the first edition of its Global Standard for Food Safety (GSFS), going on to become an internationally recognized standard of best practices in food manufacturing, storage, and distribution, and the first food safety standard to be recognized by the Global Food Safety Initiative (GFSI; discussed later). The standard covers stakeholder buy-in on continual improvement, food safety plan development, food quality management system development, manufacturing and storage site standardization, product and process control, personnel management, risk management, and trade product management.[3][4][5][6] The standard is implemented by an organization through gap assessment, documentation development, consultation and assessment, internal auditing, and resolving non-conformances to the standard.[4]

2.1.1.2 Codex Alimentarius

The Codex Alimentarius is a collection of internationally recognized food and feed standards and guidelines developed as a joint venture between the United Nation's Food and Agricultural Organization (FAO) and the World Health Organization (WHO).[5] The Codex "is intended to guide and promote the elaboration and establishment of definitions and requirements for foods to assist in their harmonization and in doing so to facilitate international trade."[7] Scope of the standards is broad, covering food hygiene; food additives and contaminants, including pesticides and drugs; packaging and labelling; sampling and analysis methods; and import and export inspection and certification.[7] It's not unusual for governments to approach the FAO seeking help with harmonizing national legal frameworks of food safety with the Codex Alimentarius.[8] Among the Codex, some of the more broadly useful standards include General Principles of Food Hygiene (CXC 1-1969)[9], General Standard for Contaminants and Toxins in Food and Feed (CXS 193-1995), and General Methods of Analysis for Contaminants (CXS 228-2001).[10]

2.1.1.3 Global Food Safety Initiative (GFSI)

The GFSI is a collection of private organizations that has developed a set of benchmarking requirements for improving food safety management programs, with a goal of making them balanced enough to be broadly applicable while remaining relevant to different countries and regions of the world.[5] Previously known as the GFSI Guidance Document[11], the GFSI Benchmarking Requirements act as a set of criteria and professional framework for food safety management programs to fulfill, formally allowing an organization to be recognized and certified by the GFSI. Certification to the GFSI Benchmarking Requirements "demonstrates an organization’s serious commitment to food safety to customers and potential customers across the world."[5] An organization seeks out a third-party certification program owner (CPO) and undergoes the auditing process, which is driven and supported by the GFSI Benchmarking Requirements.[12] GFSI is also responsible for ensuring CPOs and certification bodies meet the necessary requirements.

2.1.1.4 Hazard analysis and critical control points (HACCP)

The hazard analysis and critical control points or HACCP system has been adopted and integrated in various ways over the years[13], but at its core, the system directs organizations to focus on key areas or "critical control points" (CCPs) of vulnerability and hazard within the production process and mitigate their impact on overall food safety.[5] Though the seeds of HACCP go back to the 1970s, it wasn't until the mid-1990s that it began finding its way into formal regulatory structures in the United States, first codified as 9 CFR Parts 304, 308, 310, 320, 327, 381, 416, and 417 in July 1996.[13][14] HACCP also found its way into other standards benchmarked by the GFSI.[13] The concept of HACCP has perhaps changed slightly over the years, but the main principles remain[5]:

- Conduct a hazard analysis.

- Identify CCPs.

- Establish critical limits for those CCPs.

- Establish monitoring procedures for those CCPs.

- Establish corrective action for failed limits.

- Establish verification procedures.

- Establish record keeping and documentation procedures.

2.1.1.5 International Featured Standards (IFS)

The IFS framework is made up of a group of eight food and non-food standards, covering various processes along the food supply chain. IFS Management, who is responsible for the standards, notes that "IFS does not specify what these processes must look like but merely provides a risk-based assessment"[15] or "uniform evaluation system"[5] for them. Organizations such as food manufacturers and logistics providers can certify to the standards. Some of the more relevant to food and beverage laboratories include IFS Food (for food manufacturers), IFS Global Markets Food (for food retailers), IFS PACsecure 2 (for packaging manufactures), and IFS Global Markets PACsecure (for packaging suppliers).[15]

2.1.1.6 International Organization for Standardization (ISO) 22000

The ISO 22000 series of standards addresses how a food safety management system should be set up and operated, and how organizations can be certified to the standard by a third-party auditor.[16] ISO 22000 is based off the ISO 9000 family of quality management system standards and, like other standards, incorporates elements of HACCP.[13] The standard claims to be advantaged compared to other standards due to its comprehensive applicability across an entire organization, and across the entire food chain.[17] Major standards applicable to manufacturers with laboratories include:

- ISO/TS 22002-1:2009 Prerequisite programmes on food safety — Part 1: Food manufacturing[18]

- ISO/TS 22002-4:2013 Prerequisite programmes on food safety — Part 4: Food packaging manufacturing[19]

- ISO/TS 22002-6:2016 Prerequisite programmes on food safety — Part 6: Feed and animal food production[20]

2.1.1.7 Safe Quality Food (SQF) Program

The SQF Program, headlined by the SQF Institute and recognized by the GFSI, is a food "safety-plus-quality" management certification mechanism that covers the food supply chain from farm to fork.[5] Those who wish to be certified to SQF must comply with SQF Code, which covers a variety of topics, from aquaculture and farming to food packaging and food and feed manufacturing.[21] Like other standards, the organization wanting to be accredited finds a certified third-party auditor to administer program certification.

2.1.2 Materials

An internet search for "materials engineering standards" reveals dozens of university library research guides discussing what standards are, why they are important to materials science and engineering, and how to find them via the university's library system. Take for example UCLA's Materials Science and Engineering guide and its relatively succinct description of why standards are important to materials scientists[22]:

Standards and specifications are described as documents that describe the rules and conditions for how materials and products should be manufactured, defined, measured, tested, and applied. They are used to establish baselines or a minimum level of performance and quality control to ensure that optimal conditions and procedures for the purpose of creating compatibility with products and services from different periods and a range of sources. Specifications have a more limited range of application than standards and generally establish requirements for materials, products, or services. Standards and specifications may be issued by voluntary technical or trade associations, professional societies, national standards bodies, government agencies, or by international organizations ... Standards and specifications are of greatest utility to engineers, scientists, and those working with new innovations.

UCLA helpfully goes on to describe the types of standards one should expect to find in regards to materials science and engineering, including categorical (e.g., dimension, structure, grade, durability, safety), method-based (e.g., manufacturing, design, operational safety), testing-based (e.g., analyzing, measuring, verifying), term-based (e.g., abbreviations, symbology, preferred units), and design (e.g., execution method, safety conditions) standards.[22] As such, it would be practically impossible to address all materials-related standards in this guide. However, a small selection of examples are provided to give varying contexts of what materials engineers and manufacturers may need to consider.

2.1.2.1 American Society of Civil Engineers (ASCE) materials standards

The ASCE is a professional organization with its own library of standards, including materials standards for engineering. Examples include ASCE/T&DI/ICPI 58-16 Structural Design of Interlocking Concrete Pavement for Municipal Streets and Roadways, ASCE/SEI 19-16 Structural Applications of Steel Cables for Buildings, and ASCE/SEI 48-05 Design of Steel Transmission Pole Structures.

2.1.2.2 ASTM International Volume 15.04

ASTM International has numerous volumes of standards for materials, including Volume 15.04. This volume covers the chemical requirements for soaps and other detergents, the properties of polishes, various properties and test methods of leather, and the properties of floor coverings.[23]

2.1.2.3 Canadian Standards Association (CSA) A3000 series

The CSA produces standards for a variety of materials, including cementitious materials through its A3000 series of standards. These construction materials standards address the basics of cementitious materials, their appropriate test methods, and the equipment best used for those methods.[24]

2.1.2.4 International Organization for Standardization (ISO) 10993

Generally speaking, there are no ISO or government-sanctioned standards for the materials that can be used in medical devices, but rather there are standards that apply directly to medical devices, largely given that the overall manufacturing process has a tendency to modify the reactivity of the material used in the medical device.[25] That being said, there is an ISO standard for biocompatibility, "the ability of a device material to perform with an appropriate host response in a specific situation"[26]: the ISO 10993 series of standards.[25] These standards requires manufacturers of medical devices to collect "qualitative and quantitative data on the materials in the context of biological safety" to ensure the device's material is actually biocompatible.[25] ISO 10933 addresses chemical characterization, allowable limits of leachable substances, and in vitro cytotoxicity of medical device materials, among other things.[25]

2.1.2.5 Metal Powder Industries Federation (MPIF) Standard 35 family

The MPIF "issues standards to provide the design and materials engineer with the information necessary for specifying powder metallurgy materials which have been developed by the powder metallurgy and metal injection molding parts, powder, and equipment producers."[27] Among them is the Standard 35 family, which addresses powder metallurgy structural parts and self-lubricating bearings, as well as powder-forged steel and metal injection molded parts, including materials aspects such as "minimum strength value, grade selection, chemistry, proof testing, typical property values, and processes."[27]

2.1.3 Pharmaceutical and medical devices

Of the various manufacturing domains, pharmaceutical and medical device manufacturing arguably requires some of the most rigorous standards to ensure the good health of end users. Speaking to consumer expectations of safe, high-quality pharmaceutical products, Atouf and Venema note[28]:

The consistency in both the safety and efficacy of the drug supply required to achieve this assurance is based mainly on our reliance on compendial standards for quality and performance of drug development, review, and ongoing manufacturing. These standards are recognized in the [Food, Drug and Cosmetic Act] and play a critical role in its adulteration and misbranding provisions ... The impact of established and accepted standards—in the form of measurements and methods as well as reference materials—being a norm for drug development often goes unnoticed and unmeasured, even by those intimately involved in the field. By the very fact of being the norm, they are taken for granted. Their impact is nonetheless fundamental to the current and future efficiency of drug development as well as to the pursuit of providing safe, high-quality medicines at a reasonable price.

Similarly, harmonized medical device standards are valuable to manufacturers and end users, making it "possible to apply essential requirements" of development and manufacturing "in a uniform way." Manufacturers can adopt harmonized standards in such a way that design and documentation costs are reduced, while at the same time giving end users more confidence in the safety and efficacy of manufactured devices.[29]

Like materials standards, it's beyond the scope of this guide to try and list all pharmaceutical and medical device standards. What follows are a few examples of more critical standards in this industry.

2.1.3.1 ASTM International Volume 14.01

ASTM International covers pharmaceutical and biopharmaceutical manufacturing in its Volume 14.01. In particular, it "covers the application of process analytical technology (PAT) within the pharmaceutical and biopharmaceutical industry, highlighting PAT system management, implementation, and practices."[30]

2.1.3.2 European Pharmacopoeia standards

The European Pharmacopoeia is a compendium of standards—in the form of monographs and other documents—that provides "a legal and scientific basis for quality control during the development, production and marketing" of pharmaceuticals and their ingredients. These standards address the compositions, testing, and handling of medicines and their ingredients to better ensure the safety of consumers and a more effective product.[31] The eleventh edition contains more than 2,400 monographs, 380 general texts, and 2,800 descriptions of reagents.[32] While legally binding in European member countries, the standards also have international relevance.[31]

2.1.3.3 International Organization for Standardization (ISO) 10993, 13485, and 16142-2

As described in the previous subsection, the ISO 10993 series of standards addresses the biocompatibility of medical device materials. ISO 13485 is the primary quality management system (QMS) standard for hardware- and software-based medical devices and their demonstration of meeting or exceeding customer and regulatory requirements. By meeting the requirements of ISO 13485, the manufacturer facilitates "an improvement of processes" within their workflows over the complete lifecycle of operations.[33] ISO 16142-2 "identifies and describes the six general essential principles of safety and performance ... that apply to all medical devices, including IVD medical devices (in vitro diagnostic)," while also addressing the safety and performance requirements for designing and manufacturing medical devices.[34]

2.1.3.4 United States Pharmacopeia and National Formulary (USP-NF) standards

Like its European counterpart, the USP-NF acts as a compendium of thousands of quality standards for pharmaceutical products and their active and inactive ingredients, helping manufacturers better protect patient safety while also producing higher-quality medicines. Three broad types of standards make up the compendium: monographs, general chapters, and material reference standards. Monographs "articulate the quality expectations for a medicine" and "describe the tests to validate" the medicine's ability to meet those expectations.[35] General chapters take a broad approach to product development and manufacturing, discussing accepted processes, tests, and methods for pharmaceuticals. Material reference standards complement monographs and general chapters with their quality testing methods to ensure medicines adhere to the state requirements of monographs and general chapters.[35]

2.1.4 Other industries and standards

From our North American Industry Classification System (NAICS)-derived list of manufacturing industries in Chapter 1, we know there's more to manufacturing than food and beverage, materials, and pharmaceuticals and medical devices. Apparel, electronics, furniture, plastics, and petrochemical manufacturers—to name a few—have their own standards. It is beyond the scope of this guide to cover every industry; however, this subsection will highlight a few examples of standards that are applicable to a wide variety of other industries, including the all-important ISO 9001 standard.

2.1.4.1 British Standards Institution (BSI) standards

BSI is appointed by the United Kingdom as the national standards body and seeks to "improve the quality and safety of products, services and systems by enabling the creation of standards and encouraging their use."[36] BSI works in tandem with the ISO to address the standards needs of the U.K. Addressed among its standards are the topics of quality, supply chain, health and safety, and automation.[37] An example of a manufacturing standard is BS EN 1090, which addresses "structural/construction steel and aluminum products that are installed in a permanent manner."[38]

2.1.4.2 Global Standard's Global Organic Textile Standard (GOTS)

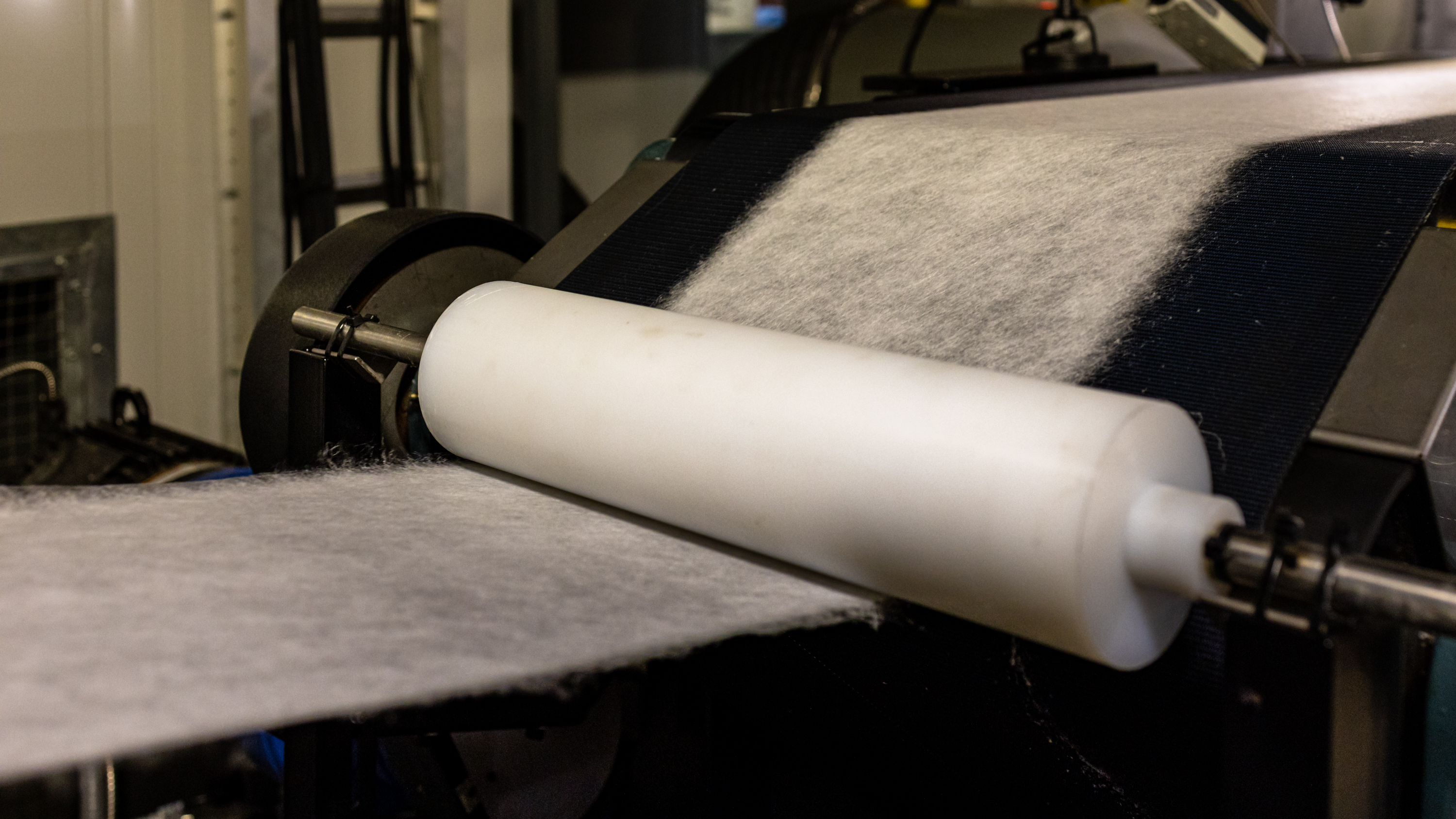

Global Standard's GOTS is described as "the worldwide leading textile processing standard for organic fibres, including ecological and social criteria, backed up by independent third-party certification of the entire textile supply chain."[39] The standard's breadth covers the entire spectrum of textile manufacturing, from design and processing to final distribution. Global Standards also provides an implementation manual for organizations with questions about the standard's implementation.[40]

2.1.4.3 International Organization for Standardization (ISO) 9001

ISO 9001 specifies the requirements for a QMS within any organization providing products and services, particularly those seeking to prove their products and services consistently meet customer and regulatory requirements and necessarily enhance customer satisfaction.[41] While it does not define product quality, by focusing on the QMS, a manufacturer typically by extension produces products of a higher quality. (Though, broadly speaking, such improvement is partly driven by the fact that there is a tendency for better performing companies to seek ISO 9001 certification.[42]) The standard applies to manufacturers big and small across any industry, and as such, ISO 9001 requires the organization to closely consider its context within its industry and business environment in order to make the most of the standard.[43]

2.1.4.4 Underwriter Laboratories (UL) standards

UL says its standards "are used to assess products; test components, materials, systems and performance; and evaluate environmentally sustainable products, renewable energies, food and water products, recycling systems and other innovative technologies."[44] When looking at their catalog of standards, the breadth of products—and therefore industries—becomes more apparent, from electrical conduit, thermostat wiring, energy storage systems, and fire extinguishers to electric gardening devices, elevator door locks and contacts, garment finishing appliances, and gasoline.[45] If it can be manufactured in your industry, UL may have a standard for it.

2.2 Regulations and laws around the world

As the end of Chapter 1 highlighted, today's regulatory focus on product safety, quality, and efficacy is largely built on the past failures, injuries, and deaths that highlighted the regulatory need.[46][47][48][49] For example, the consumption of raw milk was associated with a growing number of health issues in the mid- to late 1800s, particularly milk from unscrupulous dairy farms. In the U.S. Northeast during the 1860s, recognition was growing concerning the threat that tainted milk originating from dairy cows being singularly fed distillery byproducts had to human health. Not only was the milk generated from such cows thin and low in nutrients, but it also was adulterated with questionable substances to give it a better appearance. This resulted in many children and adults falling ill or dying from consuming the product. The efforts of Dr. Henry Coit and others in the late 1800s to develop a certification program for milk—which included laboratory testing among other activities—eventually helped plant the seeds for a national food and beverage safety program.[50] By 1939, the U.S. Public Health Services had drafted the Model Milk Health Ordinance "in order to encourage a greater uniformity of milk-control practice in the United States."[51]

While regulation can at times be overbearing and harmful, well-crafted regulations can definitely benefit our society. This can be seen with manufacturing regulations driven on safety, quality, and efficacy principles. How those regulations are implemented around the world may differ slightly, however, which should not be surprising given the cultural, political, and functional differences across regions and nations of the world.[52]

The following subsections examine some of the more critical regulations that apply to a wide variety of manufacturing industries, from various parts of the world.

2.2.1 Food and beverage

The safety and quality of food is a high priority for most countries around the world, though how that safety and quality is regulated and legislated varies, sometimes significantly. The following subsections briefly address the primary regulations and legislation enacted in seven major countries and supranational unions around the world. (It is beyond the scope of this guide to address them all.) Similarities among the countries may be seen in their goals, but it should be noted that differences—significant and nuanced—exist among them all in regards to regulatory approaches to sampling, testing, risk, and importing of products.[52][53][54][55]

2.2.1.1 Food Safety Act 1990 and Food Standards Act 1999 - United Kingdom

The Food Safety Act of 1990 and Food Standards Act of 1999 represent the core of food safety regulation in the United Kingdom, though there are other pieces of legislation that also have an impact.[56][57] The Food Safety Act of 1990 encourages entities to "not include anything in food, remove anything from food, or treat food in any way which means it would be damaging to the health of people eating it"; serve or sell food that is of a quality that "consumers would expect"; and ensure food is labeled, advertised, and presented clearly and truthfully.[56][57] The Food Standards Act of 1999 later created the UK's Food Standards Agency (FSA) "to protect public health from risks which may arise in connection with the consumption of food (including risks caused by the way in which it is produced or supplied) and otherwise to protect the interests of consumers in relation to food."[58] One of the ways the FSA does this is through enforcing food safety regulation at the local level, including within food production facilities, as well as setting ingredient and nutrition labelling policy.[59] Regulations and guidance from the FSA address not only labelling but also radioactivity monitoring, meat processing, manure management, Salmonella testing, temperature control, dairy hygiene, and more.[60]

2.2.1.2 Food Safety and Standards Act of 2006 - India

This act was enacted in 2006 to both consolidate existing food-related law and to establish the Food Safety and Standards Authority of India (FSSAI), which develops regulations and standards of practice for the manufacture, storage, distribution, and packaging of food.[61][62] However, an audit of FSSAI by the Comptroller and Auditor General of India (CAG) in December 2017 revealed some deficiencies in the FSSAI's activities, including an overall "low quality" of food testing laboratories in the country.[61] Nonetheless, the FSSAI remains the primary regulatory watchdog, developing standards and guidelines for food and enforcing those standards. This includes setting limits for food additives, contaminants, pesticides, drugs, heavy metals, and more, as well as defining quality control mechanisms, accreditation requirements, sampling and analytical techniques, and more.[62]

2.2.1.3 Food Safety Law - China

The Food Safety Law is described as "the fundamental law regulating food safety in China."[63] Enacted in 2009 and revised in 2015, the Law "builds up the basic legal framework for food safety supervision and management" and "introduces many new regulatory requirements," including "not only general requirements applicable to food and food additives, but also specific requirements for food-related products and other product categories."[63] Among these activities, the Law describes how food testing laboratories shall conduct their activities, from accreditation and sampling to testing and reporting.[64]

2.2.1.4 Food Sanitation Act and Food Safety Basic Act - Japan

The Food Sanitation Act of 1947 and the Food Safety Basic Act of 2003 represent the most important pieces of food-related legislation in Japan, though there are others. The Food Sanitation Act was originally enacted "to prevent sanitation hazards resulting from eating and drinking by enforcing regulations and other measures necessary from the viewpoint of public health, to ensure food safety and thereby to protect citizens' health."[65] The Food Safety Basic Act recognized the effects of "internationalization" and changing dietary habits, as well as scientific and technological shifts in food production, as a primary driver for modernizing food safety and sustainability in the country, and it also created the Food Safety Commission of Japan.[66] Between the two pieces of legislation, standards and specifications for food and food additives, as well as associated tools and packaging, are addressed, as are inspection standards, production standards, hygiene management, and individual food and ingredient safety.[67]

2.2.1.5 Food Safety Modernization Act (FSMA) and other acts - United States

The Food Safety Modernization Act of the United States was signed into law in January 2011, giving the US Food and Drug Administration (FDA) more regulatory authority to address the way food is grown, harvested, and processed.[13][68] It has been described by the FDA as "the most sweeping reform of our food safety laws in more than 70 years."[68] The FSMA, at its base, has five key aspects, addressing preventive controls, inspection and compliance, safety of food imports, mandatory recall response, and food partnership enhancement.[68] However, FSMA continues to evolve, with additional rules getting added since its enactment, including rules about record management, good manufacturing practice (GMP) for human food and animal feed, and laboratory accreditation (referred to as the LAAF Rule).[69]

Another important regulatory body in the US is the Food Safety and Inspection Service (FSIS), which is overseen by the US Department of Agriculture (USDA). The FSIS and its authority to regulate are derived from three different acts: the Federal Meat Inspection Act of 1906, the Poultry Products Inspection Act of 1957, and the Egg Products Inspection Act of 1970.[70] The FSIS has developed its own regulatory requirements for meat, poultry, and egg products, including for inspections, imports and exports, labeling, and laboratory testing.[71][72][73]

2.2.1.6 General Food Law Regulation (GFLR) - European Union The GFLR was enacted across the European Union in 2002 as part of Regulation (EC) No 178/2002, and it is described as "the foundation of food and feed law" for the EU.[74] Along with setting requirements and procedures for food and feed safety, the GFLR also mandated the creation of the European Food Safety Authority (EFSA), an independent body assigned to developing sound scientific advice about and providing support towards the goals of food, beverage, and feed safety in the EU.[13][74] As such, the EFSA develops broad and sector-specific guidance[75], as well as other rules related to scientific assessment of food safety matters, e.g., Regulation (EC) No 2073/2005 on microbiological criteria for foodstuffs.[76] The EFSA also develops food classification standardization tools such as the Standard Sample Description (SSD2) data model, to better ensure an appropriate "format for describing food and feed samples and analytical results that is used by EFSA’s data providers."[77]

2.2.1.7 Safe Food for Canadians Act (SFCA) - Canada

In November 2012, the SFCA was enacted to place regulatory "focus on prevention to ensure a food that is imported, exported or shipped from one province to another, is manufactured, stored, packaged and labelled in a way that does not present a risk of contamination."[78][79] Though Canadian Food Inspection Agency (CFIA) enforcement of the SFCA's regulations didn't start until January 2019[78], the consolidation of 14 sets of existing food regulations by the SFCA has managed to improve consistency, reduce administrative burden, and enable food business innovation.[80] An interpretive guide published by the CFIA, Understanding the Safe Food for Canadians Regulations: A handbook for food businesses, summarizes and explains some of the nuances of the SFCA and its 16 parts on matters such as trade, licensing, preventive controls, packaging and labeling, and traceability.[80]

2.2.2 Materials

Like materials standards, there are too many materials regulations to list for the given scope of this guide. However, several different examples are given below of materials-related regulations found in various parts of the world.

2.2.2.1 21 CFR Part 175 and 176 - United States

These two regulations from the U.S. Code of Federal Regulations system relate specifically to the materials used to package food. (While the food and beverage industry is the recipient and end user of such materials, the materials researcher and manufacturer is responsible, in part, for developing and producing materials that meet such regulations.) Part 175 dictates what substances can be used as components of adhesives and coatings in food packaging materials[81], and Part 176 addresses what substances can be used as components of paper and paperboard in food packaging materials.[82]

2.2.2.2 Building Standard Law - Japan

Japan's Building Standard Law, broadly speaking, states a minimum set of standards that must be followed concerning the construction of buildings in the country, in order to protect the health and property of those using those buildings. Given the country's infrastructure is affected by snow accumulation, earthquakes, and tsunamis, a modern approach to building regulation was required in 1950. One section of the law addresses the quality of materials used in building construction, particularly in important sections of the home such as the foundation, load-bearing walls, columns, and more. The regulation mandates that such materials must conform to the Japanese Industrial Standard or Japanese Agriculture Standard or be specifically approved by the Minister. This means manufacturers of structural steel, high-strength bolts, concrete, wood-based composite panels, membrane materials, and more are largely beholden to those standards throughout the manufacturing process.[83]

2.2.2.3 The Furniture and Furnishings (Fire) (Safety) Regulations 1988 - United Kingdom

In 1988, the U.K. made into law The Furniture and Furnishings (Fire) (Safety) Regulations, which "were introduced to help reduce the risks of injury or loss of life through fires in the home spread by upholstered furniture."[84] The regulations set out general testing requirements for foam fillings, non-foam fillings, composite fillings, and cover materials pass various material and combustion requirements.[85] Various updates have been made to the regulations over time. In 2019, the government, noting "growing evidence linking the specific flame-retardant chemicals most often used in furniture to serious long-term health impacts," acknowledged that updates to regulations on the materials used in furniture making were required, which would in turn further dictate manufacturing processes.

2.2.2.4 National Environment Protection (Used Packaging Materials) Measure 2011 - Australia

In September 2011, Australia's National Environment Protection Council made law the National Environment Protection (Used Packaging Materials) Measure 2011. Signatories of the Covenant agreed to "a voluntary system of industry self regulation" to better ensure "improved environmental outcomes" in regards to packaging material use and re-use.[86] However, a 2021 review found that the regulation was lacking in several areas, including with monitoring and enforcement. A December 2022 response by the government agreed, noting, "[l]ack of compliance monitoring and enforcement activity has undermined the effectiveness of, and confidence in, the mandatory co-regulatory arrangement and enabled some businesses to avoid their obligations." Updates to the regulations are expected by 2025, "to ensure that all packaging available in Australia is designed to be recovered, reused, recycled and reprocessed safely in line with circular economy principles. Reforming the regulation of packaging in Australia presents a significant opportunity to improve the way our packaging is designed ..."[87] As this language suggests, such regulatory changes, should they come, will further dictate the materials designed and used in manufacturing processes in the country.

2.2.2.5 Surface Coating Materials Regulations (SOR/2016-193) - Canada

Enacted in 2016, these regulations—enabled by Canada's Consumer Product Safety Act—dictate the amount of lead and mercury allowed in surface coating materials, stickers, and films under certain circumstances. The testing for those heavy metals must be done by manufacturers (or their third-party labs) "in accordance with a method that conforms to good laboratory practices."[88]

2.2.3 Pharmaceutical and medical devices

2.2.3.x Current Good Manufacturing Practice (CGMP) regulations - United States and other countries

For more on this, see the next subsection on other industries and regulations.

2.3.4 Other industries and regulations

2.3.4.x Good manufacturing practice (GMP) and current good manufacturing practice (cGMP) - United States and other countries

As a broad concept, good manufacturing practice or GMP is an organized set of standards and guidelines that allow manufacturers of most any product to better ensure their products are consistently produced and packaged to a consistent level of quality. GMP tends to cover most every step of production, from planning recipes and choosing starting materials to training personnel and documenting processes.[89] The concept of GMP is often spoken of in terms of pharmaceutical and medical device manufacturing[89][90], though it is applicable to most any other production industry.[91][92]

Closely related is the term "current good manufacturing practice" or cGMP. Both "GMP" and "cGMP" are largely interchangeable, though the latter is preferred in most regulatory language of the United States. A more nuanced take says that cGMP essentially represents the newest, most updated technologies implemented towards the goals of meeting GMP requirements.[93][94]

In the United States, cGMP—in the context of pharmaceuticals—is enshrined in numerous sections of Title 21 of the Code of Federal Regulations, including "in parts 1-99, 200-299, 300-499, 600-799, and 800-1299."[95] The FDA describes these regulations as containing "minimum requirements for the methods, facilities, and controls used in manufacturing, processing, and packing of a drug product."[95] It also states safety, efficacy, and labeling requirements for manufactured drugs. These regulations require careful attention by manufacturers, lest they face seizure of their products, legal injunction, and criminal cases.[96]

In the context of food, cGMP principles were first introduced in the U.S. in 1969 as 21 CFR Part 110, though the concept of cGMP was modernized in 2015, in 21 CFR Part 117. This led to not only broad food- and beverage-based cGMPs but also cGMPs specific to a type of ingestible, including dietary supplements, infant formula, low-acid canned food, and bottled water.[97]

GMP and cGMP contexts also exist for other manufacturing industries outside of pharmaceuticals and food, including automotive parts, medical devices, clothing, and more.[98] Additionally, these concepts are not limited to the U.S. For example, the World Health Organization has its own GMP/cGMP guidelines for pharmaceuticals and biological medicines, with more than 100 countries reportedly incorporating those guidelines into their national medicine regulations.[99]

2.3.4.x Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) Regulation - European Union

For the E.U. chemical manufacturing and other manufacturing industries depending on those chemicals, REACH represents one of the most expansive and complicated pieces of regulation in the E.U. Affecting potentially more than 140,000 substances, manufacturers of those substances are now largely responsible for identifying hazards, identifying mitigation methods for those hazards, and managing associated risks. Of particular note are "substances of very high concern" (SVHCs) and how they are authorized and restricted. This regulations means manufacturers must pay closer attention to what substances get put into their products and report on SVHCs making up more than 0.1% (by weight) of the product. These regulations may also mean the manufacturer may need to redesign their products with new substances.[100]

2.3.4.x Resolução de diretoria colegiada - RDC nº 529 - Brazil

This Brazilian resolution, effective August 2021, revised the country's List of Prohibited Substances in Personal Hygiene, Cosmetics and Perfume Products to include additional substances. While it's not clear what original legislation houses that list, this list makes clear that manufacturers of personal hygiene, cosmetic, and perfume products have to be mindful of the ingredients they use in their manufacturing processes.[101]

2.3.4.x Restriction of Hazardous Substances in Electrical and Electronic Equipment (RoHS) Directive - European Union

The E.U. uses the RoHS Directive as a means towards restricting the use of specific hazardous materials in the manufacture of electrical and electronic equipment (EEE), namely "lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE), bis(2-ethylhexyl) phthalate (DEHP), butyl benzyl phthalate (BBP), dibutyl phthalate (DBP) and diisobutyl phthalate (DIBP)."[102] By extension, the E.U. is encouraging safer alternatives for the manufacturing of EEE and fewer hazardous substances making their way into ecosystems from waste streams.

References

- ↑ Mor, Rahul S.; Bhardwaj, Arvind; Singh, Sarbjit; Sachdeva, Anish (21 October 2019). "Productivity gains through standardization-of-work in a manufacturing company" (in en). Journal of Manufacturing Technology Management 30 (6): 899–919. doi:10.1108/JMTM-07-2017-0151. ISSN 1741-038X. https://www.emerald.com/insight/content/doi/10.1108/JMTM-07-2017-0151/full/html.

- ↑ Allen, Robert H; Sriram, Ram D (1 June 2000). "The Role of Standards in Innovation" (in en). Technological Forecasting and Social Change 64 (2-3): 171–181. doi:10.1016/S0040-1625(99)00104-3. https://linkinghub.elsevier.com/retrieve/pii/S0040162599001043.

- ↑ 3.0 3.1 Pavlović, A. (26 June 2017). "What is BRC? Global food safety standard explained". Ideagen Blog. Ideagen Limited. https://www.ideagen.com/thought-leadership/blog/what-is-brc-global-food-safety-standard-explained. Retrieved 21 April 2023.

- ↑ 4.0 4.1 4.2 "BRCGS - British Retail Consortium Global Standard" (PDF). Perry Johnson Food Safety Consulting, Inc. April 2020. https://www.pjfsc.com/Downloads/BRC-Overview.pdf. Retrieved 21 April 2023.

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 5.6 5.7 "Food Safety and Quality Regulations: A Guide to Global Standards" (PDF). Eagle Product Inspection. May 2019. https://vertassets.blob.core.windows.net/download/45fe7af4/45fe7af4-0500-4163-bd2b-5dd34e824bfd/eagle_wp_food_safetyquality_regulations_guide_a4_en.pdf. Retrieved 21 April 2023.

- ↑ British Retail Consortium (August 2018). "Global Standard Food Safety" (PDF). British Retail Consortium. https://cdn.scsglobalservices.com/files/program_documents/brc_food_standard_8_0.pdf. Retrieved 21 April 2023.

- ↑ 7.0 7.1 "About Codex Alimentarius". Food and Agricultural Organization. 2022. https://www.fao.org/fao-who-codexalimentarius/about-codex/en/#c453333. Retrieved 21 April 2023.

- ↑ "Food laws & regulations". Food and Agricultural Organization. 2022. https://www.fao.org/food-safety/food-control-systems/policy-and-legal-frameworks/food-laws-and-regulations/en/. Retrieved 21 April 2023.

- ↑ "Codes of Practice". Codex Alimentarius. Food and Agricultural Organization. 2022. https://www.fao.org/fao-who-codexalimentarius/codex-texts/codes-of-practice/en/. Retrieved 21 April 2023.

- ↑ "Contaminants". Codex Alimentarius. Food and Agricultural Organization. 2022. https://www.fao.org/fao-who-codexalimentarius/thematic-areas/contaminants/en/. Retrieved 21 April 2023.

- ↑ "GFSI Releases New Edition of Benchmarking Requirements". Global Food Safety Initiative. 28 February 2017. https://mygfsi.com/press_releases/gfsi-releases-new-edition-of-benchmarking-requirements/. Retrieved 21 April 2023.

- ↑ "Certification". Global Food Safety Initiative. 2022. https://mygfsi.com/how-to-implement/certification/. Retrieved 21 April 2023.

- ↑ 13.0 13.1 13.2 13.3 13.4 13.5 Weinroth, Margaret D; Belk, Aeriel D; Belk, Keith E (9 November 2018). "History, development, and current status of food safety systems worldwide" (in en). Animal Frontiers 8 (4): 9–15. doi:10.1093/af/vfy016. ISSN 2160-6056. PMC PMC6951898. PMID 32002225. https://academic.oup.com/af/article/8/4/9/5087923.

- ↑ "61 FR 38806 - Pathogen Reduction; Hazard Analysis and Critical Control Point (HACCP) Systems". Federal Register. U.S. Government Publishing Office. 25 July 1996. https://www.govinfo.gov/app/details/FR-1996-07-25/96-17837/summary. Retrieved 21 April 2023.

- ↑ 15.0 15.1 "IFS: Global Safety and Quality Standards". IFS Management GmbH. https://www.ifs-certification.com/en/. Retrieved 21 April 2023.

- ↑ "ISO 22000 Food safety management". International Organization for Standardization. https://www.iso.org/iso-22000-food-safety-management.html. Retrieved 21 April 2023.

- ↑ "ISO/TC34/SC17". International Organization for Standardization. https://committee.iso.org/home/tc34sc17. Retrieved 21 April 2023.

- ↑ "ISO/TS 22002-1:2009 Prerequisite programmes on food safety — Part 1: Food manufacturing". International Organization for Standardization. December 2009. https://www.iso.org/standard/44001.html. Retrieved 21 April 2023.

- ↑ "ISO/TS 22002-4:2013 Prerequisite programmes on food safety — Part 4: Food packaging manufacturing". International Organization for Standardization. December 2013. https://www.iso.org/standard/60969.html. Retrieved 21 April 2023.

- ↑ "ISO/TS 22002-6:2016 Prerequisite programmes on food safety — Part 6: Feed and animal food production". International Organization for Standardization. April 2016. https://www.iso.org/standard/66126.html. Retrieved 21 April 2023.

- ↑ "SQF Code – Edition 9 Downloads". SQF Institute. 24 May 2021. https://www.sqfi.com/resource-center/sqf-code-edition-9-downloads/. Retrieved 21 April 2023.

- ↑ 22.0 22.1 "Materials Science and Engineering - Standards". UCLA Library Research Guides. UCLA Library. 1 May 2014. https://guides.library.ucla.edu/c.php?g=180271&p=1190840. Retrieved 21 April 2023.

- ↑ "ASTM Volume 15.04: Soaps And Other Detergents; Polishes; Leather; Resilient Floor Coverings". ASTM International. September 2022. https://www.astm.org/astm-bos-15.04.html. Retrieved 25 April 2023.

- ↑ "A3000-18 Cementitious materials compendium". CSA Group. 2018. https://www.csagroup.org/store/product/A3000-18/. Retrieved 25 April 2023.

- ↑ 25.0 25.1 25.2 25.3 "Material standards for medical manufacturing". Essentra Components. 28 October 2021. https://www.essentracomponents.com/en-us/news/industries/medical-equipment/material-standards-for-medical-manufacturing. Retrieved 21 April 2023.

- ↑ "Glossary of Biocompatibility Terms". U.S. Food and Drug Administration. 18 March 2021. https://www.fda.gov/medical-devices/biocompatibility-assessment-resource-center/glossary-biocompatibility-terms. Retrieved 21 April 2023.

- ↑ 27.0 27.1 "Standards". Metal Powder Industries Federation. 2023. https://www.mpif.org/Resources/Standards.aspx. Retrieved 25 April 2023.

- ↑ Atouf, Fouad; Venema, Jaap (1 August 2020). "Do Standards Matter? What is Their Value?" (in en). Journal of Pharmaceutical Sciences 109 (8): 2387–2392. doi:10.1016/j.xphs.2020.04.017. https://linkinghub.elsevier.com/retrieve/pii/S0022354920302409.

- ↑ Stinshoff, K.E. (2004). "Role of Standards in the Assessment of Medical Devices" (PDF). International Organization for Standardization. https://www.iso.org/files/live/sites/isoorg/files/archive/pdf/en/wsc-medtech_10_klaus_stinshoff_text.pdf. Retrieved 26 April 2023.

- ↑ "ASTM Volume 14.01: Statistical Methods; Hazard Potential Of Chemicals; Thermal Measurements; Manufacture Of Pharmaceutical And Biopharmaceutical Products; Healthcare Informatics". ASTM International. June 2022. https://www.astm.org/astm-bos-14.01.html. Retrieved 25 April 2023.

- ↑ 31.0 31.1 "European Pharmacopoeia - Background and Mission". Council of Europe. https://www.edqm.eu/en/background-and-mission. Retrieved 26 April 2023.

- ↑ "European Pharmacopoeia (Ph. Eur.) 11th Edition". Council of Europe. https://www.edqm.eu/en/european-pharmacopoeia-ph.-eur.-11th-edition. Retrieved 26 April 2023.

- ↑ Abuhav, Itay (2018). "1. Scope". ISO 13485:2016: a complete guide to quality management in the medical device industry (Second edition ed.). Boca Raton London New York: CRC Press, Taylor & Francis Group. pp. 1–7. ISBN 978-1-351-00077-2.

- ↑ "ISO 16142-2:2017 Medical devices — Recognized essential principles of safety and performance of medical devices — Part 2: General essential principles and additional specific essential principles for all IVD medical devices and guidance on the selection of standards". International Organization for Standardization. https://www.iso.org/standard/63940.html. Retrieved 26 April 2023.

- ↑ 35.0 35.1 "An Overview of USP Monographs". United States Pharmacopeia. https://www.usp.org/about/public-policy/overview-of-monographs. Retrieved 26 April 2023.

- ↑ "UK national standards body". British Standards Institution. 2023. https://www.bsigroup.com/en-GB/about-bsi/uk-national-standards-body/. Retrieved 26 April 2023.

- ↑ "Manufacturing". British Standards Institution. 2023. https://www.bsigroup.com/en-US/Industries-and-sectors/manufacturing-and-processing/. Retrieved 26 April 2023.

- ↑ "BS EN 1090 - Structural steel and aluminium". British Standards Institution. 2023. https://www.bsigroup.com/en-GB/our-services/product-certification/ce-mark/eu-directives/construction-products-regulation-cpr/en-1090-structural-steel/. Retrieved 26 April 2023.

- ↑ "Key Features". Global Standard GmbH. 2023. https://global-standard.org/the-standard/gots-key-features. Retrieved 26 April 2023.

- ↑ "Development and Implemetation - Implementation Manual". Global Standard GmbH. 2023. https://global-standard.org/the-standard/development-and-implementation#manual. Retrieved 26 April 2023.

- ↑ "ISO 9001:2015 Quality management systems — Requirements". International Organization for Standardization. September 2015. https://www.iso.org/standard/62085.html. Retrieved 26 April 2023.

- ↑ Heras, Iñaki; Dick, Gavin P.M.; Casadesús, Martí (2002). "ISO 9000 registration's impact on sales and profitability: A longitudinal analysis of performance before and after accreditation". International Journal of Quality & Reliability Management 19 (6): 774–791. doi:10.1108/02656710210429618.

- ↑ Abuhav, I. (2017). "Chapter 4 Context of the Organization". ISO 9001: 2015 - A Complete Guide to Quality Management Systems. CRC Press. ISBN 9781498733212. https://books.google.com/books?id=NmUlDgAAQBAJ&printsec=frontcover.

- ↑ "About". Underwriter Laboratories. 2023. https://ulstandards.ul.com/about/. Retrieved 26 April 2023.

- ↑ "Standards & Publications". Underwriter Laboratories. 2023. https://www.shopulstandards.com/Catalog.aspx. Retrieved 26 April 2023.

- ↑ Center for Policy Alternatives at the Massachusetts Institute of Technology (1980). Benefits of Environmental, Health, and Safety Regulation. U.S. Government Printing Office. pp. 100. https://books.google.com/books?id=VadeKZOzcmwC&pg=PA1.

- ↑ Asch, Peter (1988). Consumer safety regulation: putting a price on life and limb. New York: Oxford University Press. pp. 3–14. ISBN 978-0-19-504972-5. https://books.google.com/books?id=Pi_nCwAAQBAJ&pg=PA1.

- ↑ Dwyer, Tom (1991). Life and death at work: industrial accidents as a case of socially produced error. Plenum studies in work and industry. New York: Plenum Press. ISBN 978-0-306-43949-0.

- ↑ CoVan, James (1995). Safety engineering. New dimensions in engineering. New York: Wiley. ISBN 978-0-471-55612-1.

- ↑ Lytton, Timothy D. (2019). "Chapter 2: The Gospel of Clean Milk". Outbreak: foodborne illness and the struggle for food safety. Chicago ; London: The University of Chicago Press. pp. 24-64. ISBN 978-0-226-61154-9.

- ↑ U.S. Public Health Service (1939). "Milk ordinance and code: Recommended by the United States Public Health Service, 1939". U.S. Government Printing Office. http://resource.nlm.nih.gov/101528318. Retrieved 26 April 2023.

- ↑ 52.0 52.1 Buzby, J.C.; Mitchell, L. (1 November 2003). "Food Safety and Trade: Regulations, Risks, and Reconciliation". Amber Waves. U.S. Department of Agriculture, Economic Research Service. https://www.ers.usda.gov/amber-waves/2003/november/food-safety-and-trade-regulations-risks-and-reconciliation/. Retrieved 21 April 2023.

- ↑ West, D.M.; Lansang, C. (10 July 2018). "Global manufacturing scorecard: How the US compares to 18 other nations". Brookings. https://www.brookings.edu/research/global-manufacturing-scorecard-how-the-us-compares-to-18-other-nations/. Retrieved 26 April 2023.

- ↑ U.S. Government Accountability Office (February 2005). "Food Safety: Experiences of Seven Countries in Consolidating Their Food Safety Systems". https://www.gao.gov/products/gao-05-212. Retrieved 21 April 2023.

- ↑ Whitworth, J. (22 February 2022). "Report finds food testing policies different between countries". Food Safety News. https://www.foodsafetynews.com/2022/02/report-finds-food-testing-policies-different-between-countries/. Retrieved 21 April 2023.

- ↑ 56.0 56.1 "Food safety regulations". Scarborough Borough Council. 10 November 2022. Archived from the original on 03 February 2023. https://web.archive.org/web/20230203164750/https://www.scarborough.gov.uk/home/business-licensing-and-grants/food-hygeine/food-safety-regulations. Retrieved 21 April 2023.

- ↑ 57.0 57.1 "Key regulations". Food Standards Agency. 30 August 2022. https://www.food.gov.uk/about-us/key-regulations. Retrieved 21 April 2023.

- ↑ "1999 c. 28, The Food Standards Agency, Section 1". legislation.gov.uk. https://www.legislation.gov.uk/ukpga/1999/28/section/1. Retrieved 21 April 2023.

- ↑ "Food Standards Agency". Gov.uk. https://www.gov.uk/government/organisations/food-standards-agency. Retrieved 21 April 2023.

- ↑ "Guidance and regulation: Food Standards Agency (FSA)". Gov.uk. https://www.gov.uk/search/guidance-and-regulation?organisations%5B%5D=food-standards-agency&parent=food-standards-agency. Retrieved 21 April 2023.

- ↑ 61.0 61.1 "Implementation of Food Safety and Standards Act, 2006". PRS Legislative Research. https://prsindia.org/policy/report-summaries/implementation-food-safety-and-standards-act-2006. Retrieved 21 April 2023.

- ↑ 62.0 62.1 "Food Safety and Standards Act, 2006". Food Safety and Standards Authority of India. https://fssai.gov.in/cms/food-safety-and-standards-act-2006.php. Retrieved 21 April 2023.

- ↑ 63.0 63.1 Food and Agriculture Organization of the United Nations (24 April 2015). "Food Safety Law (2015)". Law and Environment Assistance Platform. United Nations Environmental Programme. https://leap.unep.org/countries/cn/national-legislation/food-safety-law-2015. Retrieved 21 April 2023.

- ↑ Foreign Agriculture Service Staff (18 May 2015). "China's Food Safety Law (2015)" (PDF). GAIN Repo. U.S. Department of Agriculture. https://apps.fas.usda.gov/newgainapi/api/report/downloadreportbyfilename?filename=Amended%20Food%20Safety%20Law%20of%20China_Beijing_China%20-%20Peoples%20Republic%20of_5-18-2015.pdf. Retrieved 21 April 2023.

- ↑ "Food Sanitation Act (Act No. 233 of 1947)". Japanese Law Translation. 24 December 1947. https://www.japaneselawtranslation.go.jp/en/laws/view/3687/en. Retrieved 21 April 2023.

- ↑ "Food Safety Basic Act" (PDF). Food Safety Commission of Japan. 23 May 2003. https://www.fsc.go.jp/english/basic_act/fs_basic_act.pdf. Retrieved 21 April 2023.

- ↑ Baker McKenzie (2018). "Japan: Food product and safety regulation". Asia Pacific Food Law Guide. https://resourcehub.bakermckenzie.com/en/resources/asia-pacific-food-law-guide/asia-pacific/japan/topics/food-product-and-safety-regulation. Retrieved 21 April 2023.

- ↑ 68.0 68.1 68.2 "Food Safety Modernization Act and Animal Food". U.S. Food and Drug Administration. 20 October 2022. https://www.fda.gov/animal-veterinary/animal-food-feeds/food-safety-modernization-act-and-animal-food. Retrieved 21 April 2023.

- ↑ "FSMA Rules & Guidance for Industry". U.S. Food and Drug Administration. 20 October 2022. https://www.fda.gov/food/food-safety-modernization-act-fsma/fsma-rules-guidance-industry#rules. Retrieved 21 April 2023.

- ↑ Food Safety and Inspection Service (21 February 2018). "Our History". U.S. Department of Agriculture. https://www.fsis.usda.gov/about-fsis/history. Retrieved 21 April 2023.

- ↑ "9 CFR Part 412 - Label Approval". Code of Federal Regulations. 31 October 2022. https://www.ecfr.gov/current/title-9/chapter-III/subchapter-E/part-412. Retrieved 21 April 2023.

- ↑ "Federal Register Rules". Food Safety and Inspection Service. https://www.fsis.usda.gov/policy/federal-register-rulemaking/federal-register-rules. Retrieved 21 April 2023.

- ↑ National Agricultural Library. "Food Safety Standards". U.S. Department of Agriculture. https://www.nal.usda.gov/human-nutrition-and-food-safety/food-safety-standards. Retrieved 21 April 2023.

- ↑ 74.0 74.1 "General Food Law". Food Safety. European Commission. https://food.ec.europa.eu/horizontal-topics/general-food-law_en. Retrieved 21 April 2023.

- ↑ "Guidance and other assessment methodology documents". European Food Safety Authority. https://www.efsa.europa.eu/en/methodology/guidance. Retrieved 21 April 2023.

- ↑ "Commission Regulation (EC) No 2073/2005 of 15 November 2005 on microbiological criteria for foodstuffs". EUR-Lex. 3 August 2020. https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32005R2073. Retrieved 21 April 2023.

- ↑ "Food classification standardisation – The FoodEx2 system". European Food Safety Authority. https://www.efsa.europa.eu/en/data/data-standardisation. Retrieved 21 April 2023.

- ↑ 78.0 78.1 "Safe Food for Canadians Act". Manitoba Government. https://www.gov.mb.ca/agriculture/food-safety/at-the-food-processor/safe-food-for-canadians-act.html. Retrieved 21 April 2023.

- ↑ "Safe Food for Canadians Act (S.C. 2012, c. 24)". Justice Laws Website. Government of Canada. 17 June 2019. https://laws-lois.justice.gc.ca/eng/acts/s-1.1/index.html. Retrieved 21 April 2023.

- ↑ 80.0 80.1 Canadian Food Inspection Agency (2018). Understanding the Safe Food for Canadians Regulations: A handbook for food businesses. Government of Canada. ISBN 9780660269856. https://inspection.canada.ca/food-safety-for-industry/toolkit-for-food-businesses/sfcr-handbook-for-food-businesses/eng/1481560206153/1481560532540?chap=0.

- ↑ "Title 21, Chapter I, Subchapter B, Part 175". Code of Federal Regulations. Office of the Federal Register; U.S. Government Publishing Office. 24 April 2023. https://www.ecfr.gov/current/title-21/chapter-I/subchapter-B/part-175?toc=1. Retrieved 26 April 2023.

- ↑ "Title 21, Chapter I, Subchapter B, Part 176". Code of Federal Regulations. Office of the Federal Register; U.S. Government Publishing Office. 24 April 2023. https://www.ecfr.gov/current/title-21/chapter-I/subchapter-B/part-175?toc=1. Retrieved 26 April 2023.

- ↑ Tomohiro, H. (July 2013). "Introduction to the Building Standard Law, Building Regulation in Japan" (PDF). Building Center of Japan. https://www.bcj.or.jp/upload/international/baseline/BSLIntroduction201307_e.pdf. Retrieved 26 April 2023.

- ↑ Office for Product Safety & Standards (July 2019). "Updating The Furniture and Furnishings (Fire) (Safety) Regulations 1988 - Government response to consultation" (PDF). Crown. https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/822072/furniture-fire-regulations-2016-consultation-government-response-july-2019.pdf. Retrieved 26 April 2023.

- ↑ "New upholstered furniture". Business Companion. Chartered Trading Standards Institute. December 2022. https://www.businesscompanion.info/en/quick-guides/product-safety/new-upholstered-furniture. Retrieved 26 April 2023.

- ↑ "National Environment Protection (Used Packaging Materials) Measure 2011". Federal Register of Legislation. Australian Government. 16 September 2011. https://www.legislation.gov.au/Details/F2011L02093. Retrieved 26 April 2023.

- ↑ "Australian Packaging Covenant". Department of Climate Change, Energy, and Environment and Water. 2023. https://www.dcceew.gov.au/environment/protection/waste/plastics-and-packaging/packaging-covenant. Retrieved 26 April 2023.

- ↑ "Surface Coating Materials Regulations". Justice Laws Website. Government of Canada. 19 December 2022. https://laws-lois.justice.gc.ca/eng/regulations/SOR-2016-193/page-1.html. Retrieved 26 April 2023.

- ↑ 89.0 89.1 "Good Manufacturing Practice (GMP) Resources". International Society for Pharmaceutical Engineering, Inc. https://ispe.org/initiatives/regulatory-resources/gmp. Retrieved 21 April 2023.

- ↑ "Medicines: Good manufacturing practices". World Health Organization. 20 November 2015. https://www.who.int/news-room/questions-and-answers/item/medicines-good-manufacturing-processes. Retrieved 21 April 2023.

- ↑ Control Engineering Staff (14 July 2007). "Regulated or not? Know good manufacturing practices (GMP)". Control Engineering. https://www.controleng.com/articles/regulated-or-not-know-good-manufacturing-practices-gmp/. Retrieved 21 April 2023.

- ↑ "Good Manufacturing Practice (GMP) Guidelines/Inspection Checklist for Cosmetics". U.S. Food and Drug Administration. 25 February 2022. https://www.fda.gov/cosmetics/cosmetics-guidance-documents/good-manufacturing-practice-gmp-guidelinesinspection-checklist-cosmetics. Retrieved 21 April 2023.

- ↑ "Difference Between GMP and cGMP". Pharma Specialists. 13 October 2021. https://www.pharmaspecialists.com/2021/10/difference-between-gmp-and-cgmp.html#gsc.tab=0. Retrieved 21 April 2023.

- ↑ "The Differences Between GMP and cGMP". Moravek Blog. Moravek, Inc. January 2021. https://www.moravek.com/the-differences-between-gmp-and-cgmp/. Retrieved 21 April 2023.