Journal:NIMS-OS: An automation software to implement a closed loop between artificial intelligence and robotic experiments in materials science

| Full article title | NIMS-OS: An automation software to implement a closed loop between artificial intelligence and robotic experiments in materials science |

|---|---|

| Journal | Science and Technology of Advanced Materials: Methods |

| Author(s) | Tamura, Ryo; Tsuda, Koji; Matsuda, Shoichi |

| Author affiliation(s) | The University of Tokyo, National Institute for Materials Science |

| Primary contact | Email: tamura dot ryo at nims dot go dot jp |

| Year published | 2023 |

| Volume and issue | 3(1) |

| Article # | 2232297 |

| DOI | 10.1080/27660400.2023.2232297 |

| ISSN | 2766-0400 |

| Distribution license | Creative Commons Attribution 4.0 International |

| Website | https://www.tandfonline.com/doi/full/10.1080/27660400.2023.2232297 |

| Download | https://www.tandfonline.com/doi/pdf/10.1080/27660400.2023.2232297 (PDF) |

|

|

This article contains rendered mathematical formulae. You may require the TeX All the Things plugin for Chrome or the Native MathML add-on and fonts for Firefox if they don't render properly for you. |

Abstract

NIMS-OS (NIMS Orchestration System) is a Python library created to realize a closed loop of robotic experiments and artificial intelligence (AI) without human intervention for automated materials exploration. It uses various combinations of modules to operate autonomously. Each module acts as an AI for materials exploration or a controller for a robotic experiments. As AI techniques, Optimization Tools for PHYSics Based on Bayesian Optimization (PHYSBO), BoundLess Objective-free eXploration (BLOX), phase diagram construction (PDC), and random exploration (RE) methods can be used. Moreover, a system called NIMS Automated Robotic Electrochemical Experiments (NAREE) is available as a set of robotic experimental equipment. Visualization tools for the results are also included, which allows users to check the optimization results in real time. Newly created modules for AI and robotic experiments can be added easily to extend the functionality of the system. In addition, we developed a graphical user interface (GUI)-driven application to control NIMS-OS. To demonstrate the operation of NIMS-OS, we consider an automated exploration for new electrolytes. NIMS-OS is available at https://github.com/nimsos-dev/nimsos.

Keywords: NIMS-OS, robotic experiments, artificial intelligence, electrochemistry, materials informatics

Introduction

The integration of robotic experiments and artificial intelligence (AI) is essential to realize automated materials exploration. If an AI system can take on some information tasks conventionally performed by human researchers, robotic systems can then execute the required physical tasks and experiments for materials exploration can proceed automatically. Such a platform may be expected to discover many novel materials and lead to substantial innovation in materials science. In recent years, significant progress has been made in the development of AI techniques and robotic devices suitable for materials exploration.

Since the launch of the Materials Genome Initiative[1], AI techniques have been actively used for materials exploration.[2][3][4] In general, materials exploration can be regarded as the problem of finding optimal materials from among a materials search space. The elements to be used in the search space must be configured, along with its composition range, process parameter range, and so forth. To solve this problem, black-box optimization methods are useful[5], and various methods have been developed and applied to fit various needs. Bayesian optimization (BO) is among the most frequently used methods in materials science.[6][7][8] In this method, promising materials can be selected in the materials search space using the predictions of their properties and the uncertainty of these predictions evaluated by Gaussian process regression. Using BO, various real materials, such as Li-ion conductive materials[9], multilayered metamaterials[10], halide perovskite[11], superalloys[12], and electrolytes[13] have been explored. BO is also used for the automated analysis of materials.[14][15] In addition, many methods have been proposed for black-box optimization in materials exploration, such as genetic algorithms[16][17], Monte Carlo tree search[18], rare event sampling[19], and algorithms using an Ising machine.[20][21][22] In the future, many more innovative methods are expected to be developed.

Robotic experiments have progressed to realize laboratory automation of chemical analysis and high-throughput screening in the field of biology.[23][24][25][26] Various types of automated analyzers and pipetting devices have been developed, and robotic arms have been used as a transport system to connect these systems. Moreover, robotic technology has been used to explore novel materials, such as thin-film materials[27][28], battery electrolytes[13][29], and photocatalysts.[30] These studies used BO to automate the proposal of promising experimental conditions. This enables a closed loop of robotic experiments and AI that can perform automated materials exploration without human intervention. This approach involves some key advantages, such as the ability to generate materials data of uniform quality and the absence of human error. In contrast, at present, robotics systems are limited in their ability to perform complex material synthesis tasks that require the skills of experts. Thus, further innovation in robotic devices will be important.

In addition to AI and robotic technologies, the control systems and software used to interlink them are also an important element to realize a closed loop without human intervention. Generally, different AI algorithms should be used depending on the motivation of a materials exploration task. Furthermore, the procedure to control the devices should depends on the nature and characteristics of the robotic systems used. Therefore, control software has thus far been developed on a case-by-case basis for different AI algorithms and robotic systems.

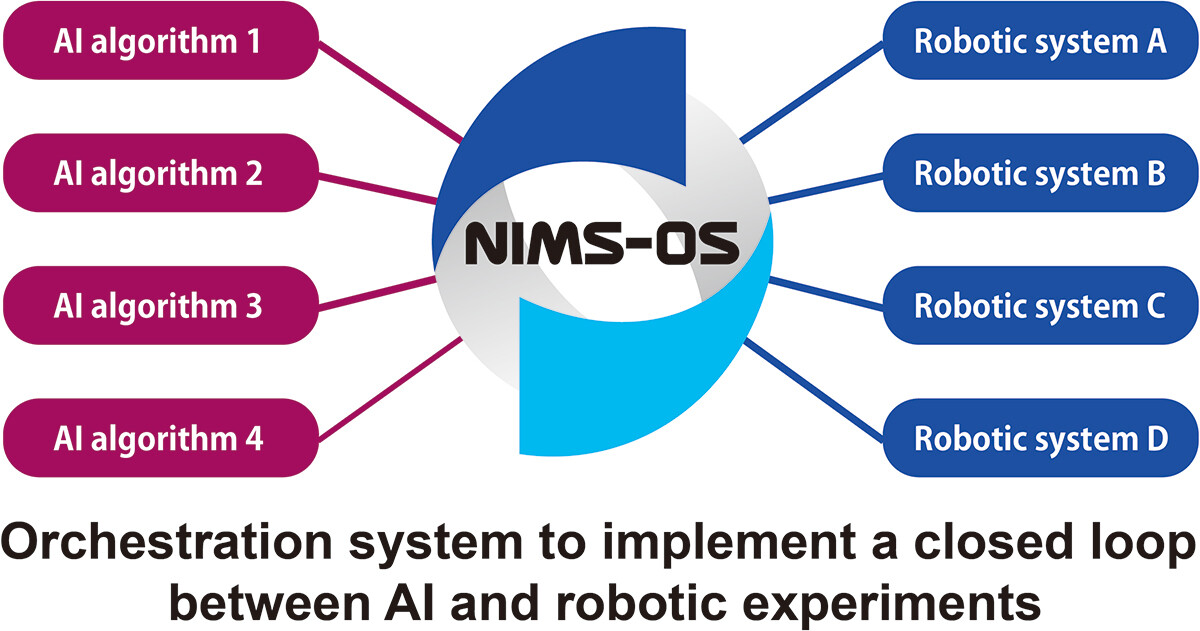

In this study, we developed NIMS-OS (NIMS Orchestration System) to realize a closed loop between AI models and robotic experiments, with the aim of establishing a generic control software system. Although this software was written in the Python programming language, we also developed a graphical user interface (GUI)-driven version to improve operability after installation. NIMS-OS treats each AI algorithm and each robotic system as separate modules (see Figure 1). This enables the implementation of a closed loop with any combination of these modules. If modules for new AI algorithms or robotic systems are prepared, new closed-loop systems can be easily controlled via NIMS-OS. One of the advantages of developing such generic control software is the establishment of technical standards for automated materials exploration. For AI algorithms, we determined standard formats for the input and output. Algorithms created according to the standard format can be immediately tested using any currently available robotic system. Specifically, we developed a standard format in which all the experimental conditions to be explored are listed in advance, and the appropriate experimental conditions that have not yet been tested are selected from the list by AI algorithms. The advantage of this approach is that it enables automated materials exploration utilizing materials databases. When utilizing materials databases, the compositional and structural information needs to be converted into materials descriptors, which serve as the materials search space. However, this search space generated from the materials databases cannot be solely defined by a continuous parameter space, and it requires a selection from the pre-listed descriptors. Of course, optimization of continuous parameters can still be handled approximately by preparing a list of grid points that discretize the continuous parameters. Furthermore, we expect this work to contribute to the development of new AI algorithms for automated materials exploration. For robotic systems, we expect modules developed based on NIMS-OS to increase the commonality of operational procedures, leading to cost reductions as new robotic experimental devices are introduced. Note that ChemOS[31] is similar to NIMS-OS; it was developed as an automation system in the field of chemistry. ChemOS specializes in BO within a defined continuous or discretized parameter space and includes several default modules for various BO methods. On the other hand, NIMS-OS offers the capability to perform automated materials explorations not only within a defined parameter space but also utilizing materials databases. In addition to BO, NIMS-OS also incorporates several default implementations of black-box optimization methods to deal with different motivations in materials explorations.

|

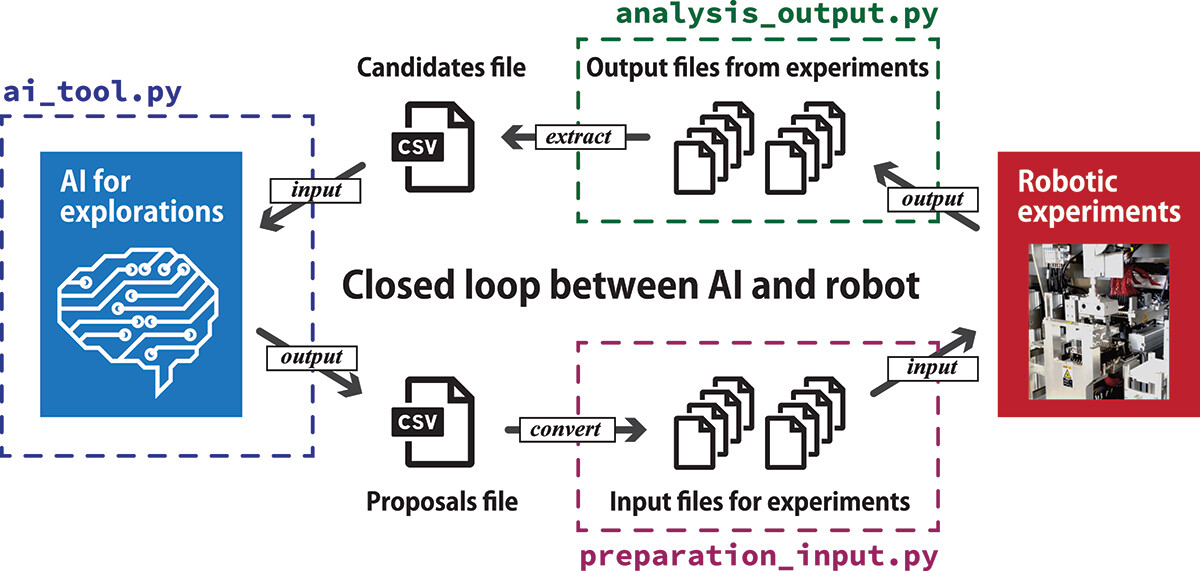

Let us briefly introduce the specifications of NIMS-OS. First, a candidates file listing experimental conditions as a materials search space should be prepared in advance. A closed loop is formed according to the following three steps (see Figure 2):

- Step 1: Select promising experimental conditions from the candidates file using an AI model.

- Step 2: Create an input file for the robotic experiments and execute the experiments.

- Step 3: Analyze the output from the experiments and update the candidates file based on the experimental results.

|

Currently, the following AI algorithms are used as modules, which are available for Step 1: (i) Optimization Tools for PHYSics Based on Bayesian Optimization (PHYSBO)[32], (ii) BoundLess Objective-free eXploration (BLOX)[33], and (iii) phase diagram construction (PDC)[34] methods, with the random exploration (RE) approach able to be selected according to the purpose of materials exploration effort. For Steps 2 and 3, a STANdard module (STAN) is provided for robotic experiments, which enables operation checks even without devices, along with a module for NIMS Automated Robotic Electrochemical Experiments (NAREE).[13][35] We plan to continue developing additional modules for this system.

The reminder of this study is organized as follows. The next section describes the preparation of a candidates file storing experimental conditions, followed by an introduction to the available modules for the AI and robotic experiments in NIMS-OS. Then the use of the Python code, and the usage of the GUI version is explained. As a demonstration, the results of an autonomous electrolyte exploration via a closed-loop approach using PHYSBO and NAREE in NIMS-OS are described. Finally, this work concludes with some discussion and suggests some important avenues for further research.

Preparation of candidates for experimental conditions

A major feature of NIMS-OS is that a data file listing candidate experimental conditions is prepared in advance (we refer to this data file a candidates file). In general, because there are many candidates, conducting experiments in all possible conditions is impractical. Thus, automated materials exploration proceeds by selecting promising experimental conditions from these listed candidates. This makes the closed-loop strategy more generalizable. That is, a variety of exploration motivations and robotic systems can be handled by NIMS-OS.

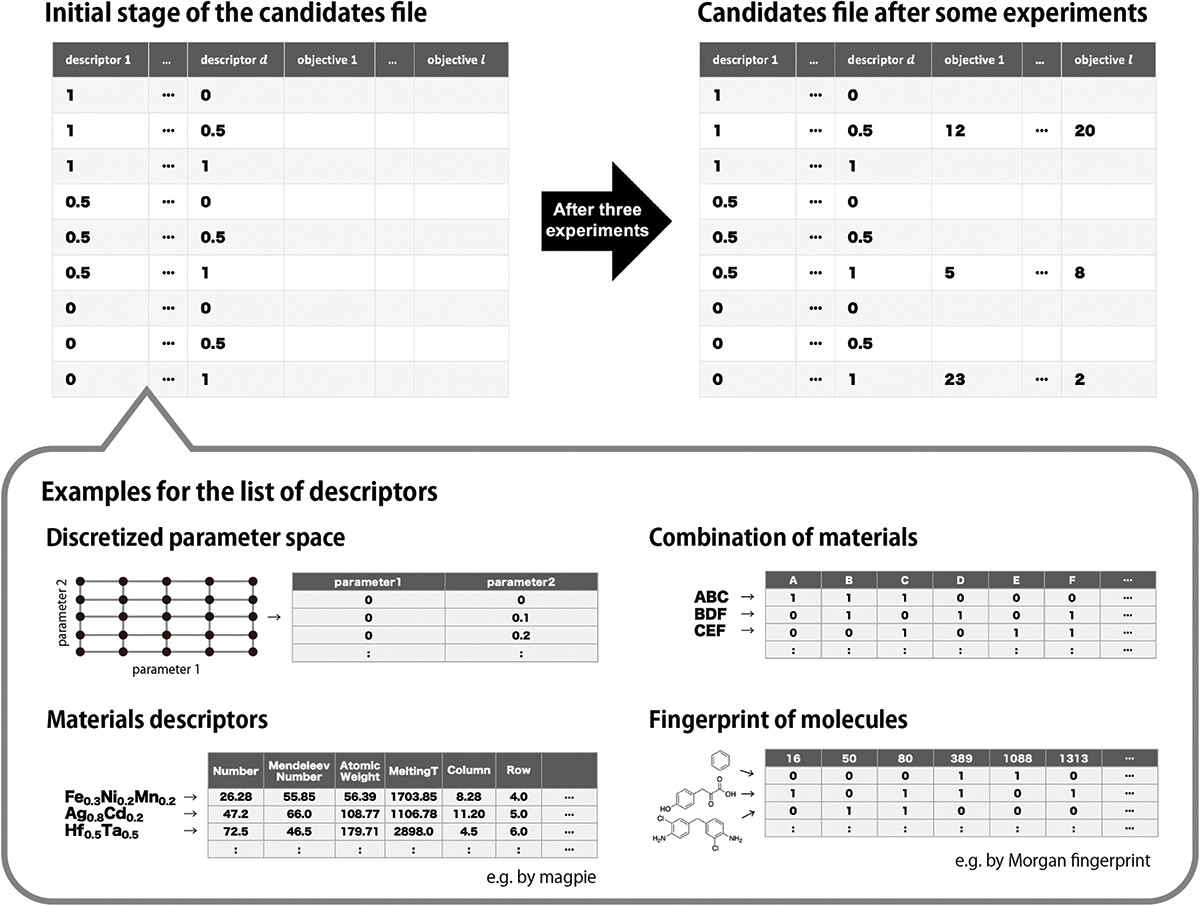

The experimental condition is expressed as a real-valued vector . This condition is prepared with information such as the compositions and structures of materials and the processes required to synthesize them. If the number of candidates for the experimental conditions is N, the dataset for candidates is defined as . The initial candidates file is created by this dataset D. An example of a candidates file with l objective functions is presented in Figure 3. All the candidates of D are written in the first d columns. In this part, there should be no empty spaces. The next l columns are used for the objective function values. In this part, at the initial stage, all cells are empty because experiments have not been performed for all the experimental conditions.

|

In NIMS-OS, some promising conditions are selected from among those listed in the candidates file using AI models (available algorithms are described in the next section). When the values of objective functions are obtained by performing experiments, the objective functions in the candidates file are updated accordingly. That is, when the experiments are completed for M experimental conditions, only results for M conditions are entered at the l columns for the objective functions. Thus, at the next step, the experimental conditions are selected from among candidates.

Modules in NIMS-OS

In this section, we introduce the modules included in NIMS-OS for AI algorithms and robotic systems. In the present work, we prepared four and two types of modules as AI algorithms and robotic systems, respectively.

AI algorithms

To select promising experimental conditions, three types of AI algorithms are implemented as standard in NIMS-OS. In addition, random exploration can be selected. Each algorithm is briefly explained in this subsection. In the future, more algorithms will be made available.

Bayesian optimization: PHYSBO

BO is an optimization technique using machine learning (ML) prediction. In this method, by using Gaussian process regression, the value of an objective function is predicted when the experimental conditions are input. The next promising experimental conditions are then selected based on the prediction values. Here, because the Gaussian process can evaluate not only the mean value of the prediction but also its variance, an acquisition function defined by mean and variance can be used to make the selection. In NIMS-OS, BO can be performed using the Python package PHYSBO.[32] PHYSBO supports single- and multi-objective optimizations, and multiple proposals are calculated. Note that the number of objective functions is recommended to be no more than three due to excessively large computational time with higher values. In NIMS-OS, Thompson sampling is used to define the acquisition function for rapid calculation. The key point in using PHYSBO is that the exploration is performed to maximize the objective functions. Thus, if a material with the smaller properties is explored, we need to add a negative value to the objective functions.

Boundless objective-free exploration: BLOX

BLOX is a Python package that performs boundless objective-free exploration. It is based on an algorithm designed to select the next experimental conditions, to perform uniform sampling in the space of the objective functions. For materials science, curious materials can be found using BLOX. Specifically, BLOX trains ML models to predict objective functions from experimental conditions. Experimental conditions that realize uniform sampling in the space of objective functions are found based on the Stein discrepancy evaluated using the prediction results. In NIMS-OS, a modified version of the BLOX algorithm that can propose multiple candidates is implemented. To select multiple candidates, after the experimental condition with the largest Stein discrepancy is selected, another condition is selected when the predicted values of the selected condition are regarded as a correct value. This procedure is iterated, and we obtain multiple proposals. In NIMS-OS, random forest regression is used as a prediction model. Although BLOX can handle any number of objective functions, it is recommended that the number of the objective functions be limited to three or four, because exploration in more dimensions requires more time. BLOX has been used to search chemical spaces[33] and to explore superhard materials.[39]

Phase diagram construction: PDC

PDC is a Python package that can create a detailed phase diagram with a small number of experiments. To investigate a phase diagram, PDC proposes promising experimental conditions for the next experiment by using active learning. Specifically, uncertainty sampling based on the label propagation method finds uncertain points in the phase diagram, and these uncertain points are proposed for the next experiments. PDC was developed to propose multiple experimental conditions for batch experiments.[40] In NIMS-OS, the least confident score is used as an uncertainty score to evaluate uncertain points. Note that, for PDC, the objective function is the phase name or an index of phases, and thus only a one-dimensional objective function can be specified in the candidates file. PDC has been used to create new phase diagrams for the growth conditions of thin film[41] and to determine large and small areas of creep phenomena in polymer materials.[42]

Random exploration: RE

In RE, the next candidate experimental condition is selected randomly. This approach can be used to generate initial data before executing AI algorithms when no experimental data have yet been recorded. Furthermore, it can also be used to generate data for comparison as new AI algorithms can be developed.

Robotic experiments

The module for robotic experiments comprises two Python scripts. The first script creates input files for robotic experiments according to the experimental conditions selected by the AI and commands a robot to begin the experiment. The second script analyzes the experimental results when the experiments are finished and updates the candidates file. At present, two types of modules are implemented in NIMS-OS: STAN and NAREE.

Standard module for robotic experiments: STAN

STAN is a virtual implementation of the procedure for conducting robotic experiments. Thus, NIMS-OS can be run virtually using this module, even without a robotic device. In this module, the following steps are executed:

- Create the input files for the robotic experiments in an appropriate folder according to the experimental conditions selected by the AI. In this standard module, we simply create a text file with a date as its name.

- Send a signal to the robotic system to begin the experiments. Depending on the machine, various cases can be considered, such as sending a start signal via serial communication. In this standard module, we assume that the experiments are begun by storing the inputend.txt file in the specified folder.

- Wait until the robotic experiments are completed. This step includes various operations, such as receiving signals from the robot when the experiment is finished. This standard module assumes that the robot outputs outputend.txt file to indicate that the experiment is finished, and NIMS-OS continues waiting until this file appears.

- Read the files of experimental results and extract the values of objective functions. Here, the case of simply reading results.csv, which contains the objective function values, is implemented.

- Update the candidates file according to the values extracted in (4).

Steps (1) and (2) are performed by preparation_input.py, and analysis_output.py conducts steps (3)-(5). In practice, for use with actual robotic systems, new modules can be created according to this standard module.

Additionally, this module can also facilitate closed-loop materials exploration between AI and experiments for processes that are time-consuming and cannot be partially automated. The procedure is as follows: When the proposals.csv file is generated, NIMS-OS automatically enters a sleep mode until experimental results are obtained. Based on the information in proposals.csv, the corresponding manual experiments are conducted. Once the objective function values are obtained through the experiments, a results.csv file is created, containing the objective function values corresponding to each line in proposals.csv. The results.csv file, along with an empty file named outputend.txt, is stored in the specified folder where the experimental results are output. Subsequently, NIMS-OS restarts and generates a new proposals.csv file.

NIMS automated robotic electrochemical experiments (NAREE) system: NAREE

As a robotic system for materials science, the NIMS Automated Robotic Electrochemical Experiments (NAREE) system[13][35] can be used in NIMS-OS. NAREE comprises a liquid-handling dispenser, an electrochemical measurement unit, and a robotic arm. By using a microplate-based electrochemical cell equipped with electrodes, the performance of electrolytes prepared by mixing solution by a liquid handling dispenser is electrochemically evaluated in a high-throughput manner. This module was developed according to the procedures of the previously described STAN.

Usage of the NIMS-OS Python version

Install

NIMS-OS is written in Python3 programming language (version 3.6 or higher is required), and it can be installed via PyPI as follows:

- $ python3 -m pip install nimsos

If this installation is successful, the following packages are also installed or updated automatically:

- Cython

- matplotlib

- numpy

- physbo

- scikit-learn

- scipy

Basic usage

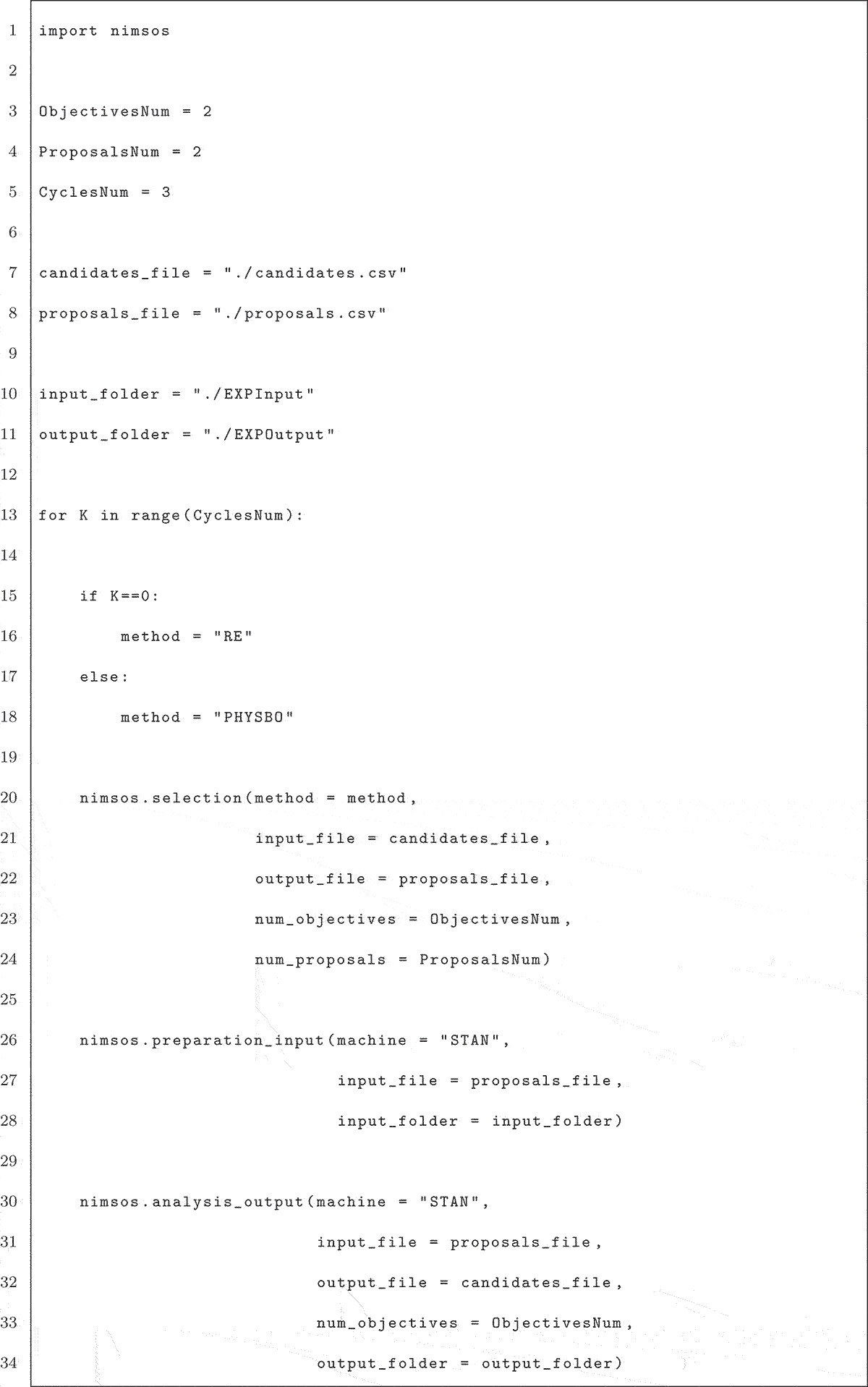

We show a small example program (Program 1) in which PHYSBO is performed. In this program, assuming no experimental results in the candidates file, random exploration is performed in the first cycle.

Assignment of parameters and candidates file

First, the parameters for closed-loop experiments are defined. For example, when the number of objective functions is two, the number of proposals for each cycle is two, and the number of cycles is three. We define this in the code as follows:

- ObjectivesNum = 2ProposalsNum = 2CyclesNum = 3

Next, we specify a .csv file containing the candidates of experimental conditions, which is prepared as described under "Preparation of candidates for experimental conditions.:

- candidates_file = “./candidates.csv”

The name of the file that will contain the experimental conditions selected by the AI is as follows:

- proposals_file = “./proposals.csv”

We specify the folder name where the input files for the robotic experiments are stored and the folder name where the results from the experiments are output, respectively, as follows:

- input_folder = “./EXPInput”

- output_folder = “./EXPOutput”

Execution of AI

nimsos.selection is a class to select the next experimental conditions with the help of the AI. For example, nimsos.selection is used as follows:

- nimsos.selection(method = “PHYSBO”,

- input_file = candidates_file,

- output_file = proposals_file,

- num_objectives = ObjectivesNum,

- num_proposals = ProposalsNum)

The parameters of the method in this class (Program 1) indicate the module for AI algorithms. For the method, "PHYSBO" (Bayesian optimization), "BLOX" (objective free search), "PDC" (phase diagram construction), and "RE" (random exploration) are specified. The experimental conditions are selected from the data without the values of objective functions among input_file. In addition, selected conditions are outputted to output_file. For num_objectives, the number of objectives is input, and the number of proposals is specified as num_proposals. In general, although many hyperparameters should be considered to use the AI, they are determined automatically in NIMS-OS. Note that if there are no experimental results in the candidates file, only "RE" is used. For "PHYSBO," "BLOX," and "PDC," some values of objective functions must be stored in the candidates file.

|

Preparation of input files for robotic experiments and execution of experiments

nimsos.preparation_input is a class to prepare the input files for robotic experiments and send the start message to the robot. For example, nimsos.preparation_input is used as follows.

- nimsos.preparation_input(machine = “STAN”,

- input_file = proposals_file,

- input_folder = input_folder)

The parameter of machine selects the module of robotic experiments. For machine, "STAN," which is the standard module for this procedure, and "NAREE" (NIMS automated robotic electrochemical experiments) are used. For input_file, the experimental conditions selected by the AI are specified. In addition, the folder in the computer where the input files for robotic experiments are stored is referred to as the input_folder. In the nimsos.preparation_input module, the two functions make_machine_file() and send_message_machine() should be modified depending on the robotic systems used. The former creates the input files for robotic experiments from selected experimental conditions, whereas the latter sends the message to begin the robotic experiments.

Analysis of output files from experiments and update of candidates file

nimsos.analysis_output is a class used to analyze the experimental results and update the candidates file. For example, nimsos.analysis_output is used as follows:

- nimsos.analysis_output(machine = “STAN”,

- input_file = proposals_file,

- output_file = candidates_file,

- num_objectives = ObjectivesNum,

- output_folder = output_folder)

The parameter of machine is the same as that found in the nimsos.preparation_input module, which selects the module for robotic experiments. Here, "STAN" and "NAREE" can be selected. For input_file, the experimental conditions selected by the AI are specified, and output_file is the name of the candidates file. The file specified by output_file is updated by this module. In addition, for num_objectives, the number of objectives is input. For output_folder, the folder in the computer where the results from robotic experiments are output is specified. In the nimsos.analysis_output module, two functions extract_objectives() and recieve_exit_message() should be modified depending on the robot systems. The former extracts the values of objective functions from the output files of robotic experiments, and the latter receives the message when the robotic experiments are finished. If "NAREE" is selected, objectives_info should be specified as a dictionary indicating which objective function is extracted from the experimental results.

Visualization of the results

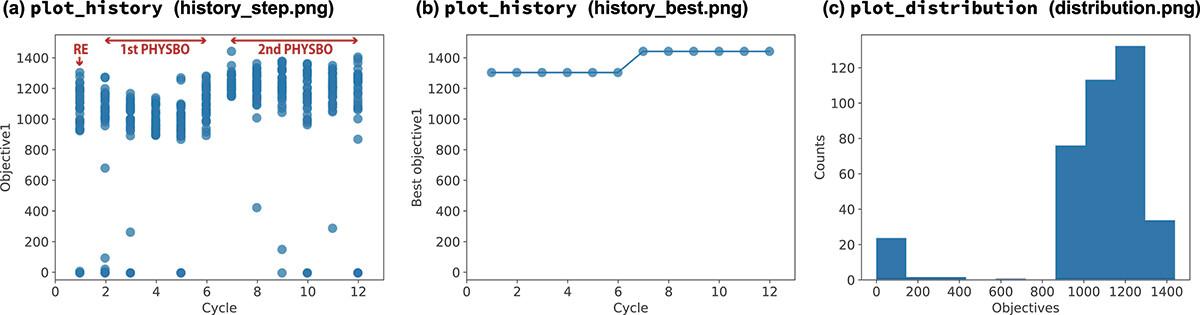

By using nimsos.visualization, the figures of the results are obtained. When this module is used, the new folder named "fig" is prepared in advance in the same folder where the main script is stored. The figures are output to this folder. nimsos.visualization.plot_history and nimsos.visualization.plot_distribution.plot create figures for the history and distributions of objective functions, respectively. These modules are useful when using AI algorithms other than PDC. In contrast, nimsos.visualization.plot_phase_diagram.plot creates the predicted phase diagram when PDC is used as an AI algorithm.

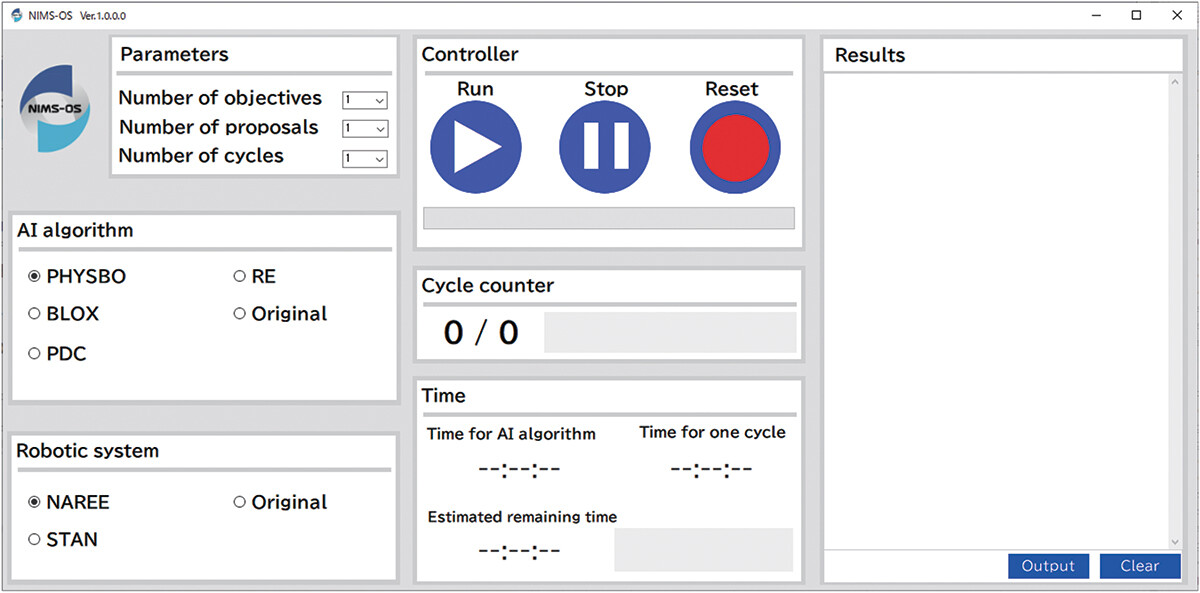

Usage of the NIMS-OS GUI version

A GUI version of NIMS-OS has been developed for easy execution, which is available at https://github.com/nimsos-dev/nimsos-gui. This can be used after installing the required Python version, as described in the prior section, and performing the installation as described in the manual (https://nimsos-dev.github.io/nimsos/docs/en/index.html). Figure 4 shows the operation screen of the NIMS-OS GUI version. In this GUI version, the name of the candidates file is fixed to candidates.csv, and the name of the proposals file is fixed to proposals.csv.

|

The execution procedure is as follows:

- Specify the number of objectives, proposals, and cycles in the "Parameters" section.

- Select the method to be used in the AI algorithm section. If we use a newly created module for AI method named "ai_tool_original.py," click on Original.

- Select the robotic system in the Robotic system section. If we use a newly created module for robotic systems named "preparation_input_original.py" and "analysis_output_original.py," click on Original.

- Press the "Run" button on the "Controller" section to begin automated materials exploration.

When NIMS-OS is started, the Cycle counter begins to operate. Furthermore, in the "Time" section, the amount of time required to execute the AI algorithm and a single cycle are measured, and the remaining time is also output. The standard output of the Python version is displayed in real time in the "Results" section, and these output results can be saved as a file by pressing the Output button. In addition, to pause the automated exploration, the user can press the "Stop" button of the "Controller" section. Note that pressing this button does not stop the process immediately, but when the candidates file is updated, NIMS-OS is stopped. To reset the settings, press the "Reset" button on the Controller. The operation with NAREE is shown as a video (Supplemental Movie 1). Note that even for processes that cannot be partially automated, the closed loop between AI and manual experiments can still be achieved by selecting STAN in the "Robotic system" section, as explained prior.

Application

To demonstrate the effectiveness of NIMS-OS for the application of automated robotic experiments, we applied the NIMS-OS for NAREE system and performed an exploration for multi-component electrolytes that maximize the performance of lithium metal electrode. The anode-free type microplate based electrochemical cells were fabricated using LiFePO4 as positive electrode and Cu foil as negative electrode. The cells were subjected to a charging process with capacity limitation of 0.05 mAh. After that, the cells were subjected to a discharge process. Here, we defined the discharge time as a one-dimensional objective function. In this case, the longer discharge time represents the better battery performance (higher capacity). Using such an experimental setup, a combination of electrolyte additives was optimized to maximize the discharge time. Five different additives were selected from a list of 16 compounds (Table 1) and injected into an electrochemical cell containing 1 M LiTFSI in TEGDME. In this case, the number of candidates for combination of electrolyte additives is . The candidate files for this experiment were prepared in a similar manner as shown in Figure 3 (combination of materials). In our experiment, 32 electrochemical cells were prepared in one microplate and 32 experiments were performed in parallel for two hours.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

For the autonomous experiments for searching multi-component electrolytes using the NAREE system operated by NIMS-OS, at first, 32 parallel experiments (one microplate) were performed by random exploration using RE because we do not have initial data at this stage. After obtaining the initial data by RE, the next five cycles of experiments (five microplates) were performed by BO using PHYSBO. Notably, a fully automated experiment was continuously conducted without any human intervention for 10 hours. After that, addition six cycles of experiments (six microplates) were also performed by BO. In total, 384 experiments were performed. The obtained results can be visualized by using nimsos.visualization in the Python version of NIMS-OS, and the time course of the objective function and the histogram distribution of the results in the total 384 experiments were summarized in Figure 5. The results clearly revealed that the best electrolyte composition was discovered at the seventh experimental cycle. In Table 2, the details of electrolyte composition for the top 10 samples that enhanced the discharge time were summarized. The electrolyte—containing 100 mM LiPF6, 100 mM LiTFSI, 2 vol.% PC, 2 vol.% FEC, and 2 vol.% VC—exhibits the highest discharge time of 1,439.09 seconds. It should be noted that the possible maximum discharge time is 1,800 seconds since the current density during discharge was set to 0.1 mA. Thus, there is still much room for improvement of battery performance. In addition, there can be seen that most of the top 10 samples contain VC and/or FEC. These results are essentially consistent with the knowledge in this field that VC and FEC have a positive effect for improving the performance of the lithium metal electrode.[43][44]

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Conclusion

In this study, we developed NIMS-OS to implement a closed loop of AI and robotic experiments for automated materials exploration. We anticipate that this software can serve as a generic control system. To use NIMS-OS, a candidates file listing experimental conditions as a materials search space should be prepared in advance. This allows various problems for automated materials exploration to be commonly performed in NIMS-OS. Establishing standards for automated materials exploration is a key advantages of such generic control software. Using NIMS-OS and the NAREE system, we also demonstrated an example of automatic exploration for electrolytes.

The compatibility with original robotic systems other than NAREE is discussed. We believe that the most crucial aspects of integrating other robotic systems lie in providing instructions to initiate the robot and determining the completion of the robotic experiment. Regarding the former, the current NAREE system is designed to automatically start an experiment when an input file is stored in a specified folder. Therefore, by making slight modifications to the existing Python script, original robotic systems with this functionality can be easily integrated into NIMS-OS. Even if the PC controlling the experimental system and the PC running the NIMS-OS are different, the robot can be started by sharing the specified folder using a file-sharing service or network-attached storage (NAS). However, if the experimental systems require voltage signal control or application programming interface (API) control, specific Python code needs to be developed. The development of Python code for voltage signal control or API control is considered a future prospect. Regarding the latter, the experimental results will always be output in the specified folder. Therefore, it is sufficient to determine whether the result files have been generated or not, even if the robotic systems are changed. Furthermore, there may be cases where the experimental system can only be fully controlled by the GUI-driven software. In such cases, it is necessary to manually press a button on the GUI control screen to initiate the robot. However, an automated closed loop can be achieved by installing Robotic Process Automation (RPA) on the PC that controls the experimental system.[15] For example, with RPA, the following operations can be performed: (i) identifying the presence of an input file in the specified folder, (ii) providing instructions to initiate the experiments on the GUI operation screen that controls the experimental system, and (iii) deleting the input file once it is confirmed that the experimental results have been generated. Thus, we believe that the current NIMS-OS is designed to be easily adaptable to a variety of original robotic systems in materials science.

At present, NIMS-OS does not include a sufficient set of available AI algorithms and robotic experimental systems. For the further growth of this OS, developing and releasing more modules for various AI algorithms and robotic systems will be essential. The NAREE system used in this study can perform sequential operations since all evaluations of proposed experimental conditions by robotic experiments are completed within the same timeframe. However, in realistic experiments, the costs associated with synthesis, device fabrication, and evaluation strongly depend on the specific experimental conditions. In such cases, waiting for all experiments to be completed would be inefficient. To address this issue, BO introduces the concept of asynchronous parallel global optimization.[45][46] Therefore, it is necessary to develop a module within NIMS-OS that can facilitate asynchronous parallel optimization. Furthermore, in automated materials exploration, a greater amount of experimental data is generated compared to human experiments. Thus, the ability to store, share, and utilize experimental data for secondary purposes should be implemented as extensions in NIMS-OS. Specifically, a module that facilitates the automatic transfer of data to external storage or data repositories will be essential in enhancing data sharing and utilization. We will continue to enhance the extensions available for NIMS-OS to develop it as a game changer for digital transformation (DX) in materials science.

Supplemental material

- Supplemental Movie 1 (.mp4; 12,302 KB)

Abbreviations, acronyms, and initialisms

- AI: artificial intelligence

- BO: Bayesian optimization

- BLOX: BoundLess Objective-free eXploration

- DMSO: dimethyl sulfoxide

- EC: ethylene carbonate

- FEC: fluoroethylene carbonate

- GUI: graphical user interface

- LiBETI: lithium bis(pentafluoroethanesulfonyl)imide

- LiBOB: lithium bis(oxalate)borate

- LiTFSI: lithium bis(trifluoro methanesulfonyl)imide

- ML: machine learning

- NAREE: NIMS Automated Robotic Electrochemical Experiments

- NIMS-OS: NIMS Orchestration System

- NMP: N-methyl-2-pyrrodione

- PC: propylene carbonate

- PDC: phase diagram construction

- PHYSBO: Optimization Tools for PHYSics Based on Bayesian Optimization

- RE: random exploration

- STAN: STANdard module

- VC: vinylene carbonate

Acknowledgements

The authors thank Masahiko Demura, Hideki Yoshikawa, and Masanobu Naito for valuable discussions. The authors also thank Kazuha Nakamura for experimental contributions, and thank Satoshi Murata, Daisuke Ryuno, and Hiromichi Taketa for the development of NIMS-OS.

Funding

The work was supported by the MEXT Program: Data Creation and Utilization-Type Material Research and Development Project [JPMXP1122712807].

Correction statement

This article has been republished with minor changes. These changes do not impact the academic content of the article.

Supplementary data

Supplemental data for this article can be accessed online at https://doi.org/10.1080/27660400.2023.2232297.

Conflict of interest

No potential conflict of interest was reported by the author(s).

References

- ↑ White, Ashley (1 August 2012). "The Materials Genome Initiative: One year on" (in en). MRS Bulletin 37 (8): 715–716. doi:10.1557/mrs.2012.194. ISSN 0883-7694. http://link.springer.com/10.1557/mrs.2012.194.

- ↑ Ramprasad, Rampi; Batra, Rohit; Pilania, Ghanshyam; Mannodi-Kanakkithodi, Arun; Kim, Chiho (13 December 2017). "Machine learning in materials informatics: recent applications and prospects" (in en). npj Computational Materials 3 (1): 54. doi:10.1038/s41524-017-0056-5. ISSN 2057-3960. https://www.nature.com/articles/s41524-017-0056-5.

- ↑ Schmidt, Jonathan; Marques, Mário R. G.; Botti, Silvana; Marques, Miguel A. L. (8 August 2019). "Recent advances and applications of machine learning in solid-state materials science" (in en). npj Computational Materials 5 (1): 83. doi:10.1038/s41524-019-0221-0. ISSN 2057-3960. https://www.nature.com/articles/s41524-019-0221-0.

- ↑ Ling, Chen (18 February 2022). "A review of the recent progress in battery informatics" (in en). npj Computational Materials 8 (1): 33. doi:10.1038/s41524-022-00713-x. ISSN 2057-3960. https://www.nature.com/articles/s41524-022-00713-x.

- ↑ Terayama, Kei; Sumita, Masato; Tamura, Ryo; Tsuda, Koji (16 March 2021). "Black-Box Optimization for Automated Discovery" (in en). Accounts of Chemical Research 54 (6): 1334–1346. doi:10.1021/acs.accounts.0c00713. ISSN 0001-4842. https://pubs.acs.org/doi/10.1021/acs.accounts.0c00713.

- ↑ Ueno, Tsuyoshi; Rhone, Trevor David; Hou, Zhufeng; Mizoguchi, Teruyasu; Tsuda, Koji (1 June 2016). "COMBO: An efficient Bayesian optimization library for materials science" (in en). Materials Discovery 4: 18–21. doi:10.1016/j.md.2016.04.001. https://linkinghub.elsevier.com/retrieve/pii/S2352924516300035.

- ↑ Packwood, Daniel (2017). Bayesian Optimization for Materials Science. SpringerBriefs in the Mathematics of Materials. 3. Singapore: Springer Singapore. doi:10.1007/978-981-10-6781-5. ISBN 978-981-10-6780-8. http://link.springer.com/10.1007/978-981-10-6781-5.

- ↑ Jin, Yimeng; Kumar, Priyank V. (2023). "Bayesian optimisation for efficient material discovery: a mini review" (in en). Nanoscale 15 (26): 10975–10984. doi:10.1039/D2NR07147A. ISSN 2040-3364. http://xlink.rsc.org/?DOI=D2NR07147A.

- ↑ Homma, Kenji; Liu, Yu; Sumita, Masato; Tamura, Ryo; Fushimi, Naoki; Iwata, Junichi; Tsuda, Koji; Kaneta, Chioko (18 June 2020). "Optimization of a Heterogeneous Ternary Li 3 PO 4 –Li 3 BO 3 –Li 2 SO 4 Mixture for Li-Ion Conductivity by Machine Learning" (in en). The Journal of Physical Chemistry C 124 (24): 12865–12870. doi:10.1021/acs.jpcc.9b11654. ISSN 1932-7447. https://pubs.acs.org/doi/10.1021/acs.jpcc.9b11654.

- ↑ Sakurai, Atsushi; Yada, Kyohei; Simomura, Tetsushi; Ju, Shenghong; Kashiwagi, Makoto; Okada, Hideyuki; Nagao, Tadaaki; Tsuda, Koji et al. (27 February 2019). "Ultranarrow-Band Wavelength-Selective Thermal Emission with Aperiodic Multilayered Metamaterials Designed by Bayesian Optimization" (in en). ACS Central Science 5 (2): 319–326. doi:10.1021/acscentsci.8b00802. ISSN 2374-7943. PMC PMC6396383. PMID 30834320. https://pubs.acs.org/doi/10.1021/acscentsci.8b00802.

- ↑ Sun, Shijing; Tiihonen, Armi; Oviedo, Felipe; Liu, Zhe; Thapa, Janak; Zhao, Yicheng; Hartono, Noor Titan P.; Goyal, Anuj et al. (1 April 2021). "A data fusion approach to optimize compositional stability of halide perovskites" (in en). Matter 4 (4): 1305–1322. doi:10.1016/j.matt.2021.01.008. https://linkinghub.elsevier.com/retrieve/pii/S2590238521000084.

- ↑ Tamura, Ryo; Osada, Toshio; Minagawa, Kazumi; Kohata, Takuma; Hirosawa, Masashi; Tsuda, Koji; Kawagishi, Kyoko (1 January 2021). "Machine learning-driven optimization in powder manufacturing of Ni-Co based superalloy" (in en). Materials & Design 198: 109290. doi:10.1016/j.matdes.2020.109290. https://linkinghub.elsevier.com/retrieve/pii/S0264127520308261.

- ↑ 13.0 13.1 13.2 13.3 Matsuda, Shoichi; Lambard, Guillaume; Sodeyama, Keitaro (1 April 2022). "Data-driven automated robotic experiments accelerate discovery of multi-component electrolyte for rechargeable Li–O2 batteries" (in en). Cell Reports Physical Science 3 (4): 100832. doi:10.1016/j.xcrp.2022.100832. https://linkinghub.elsevier.com/retrieve/pii/S2666386422001023.

- ↑ Ozaki, Yoshihiko; Suzuki, Yuta; Hawai, Takafumi; Saito, Kotaro; Onishi, Masaki; Ono, Kanta (5 June 2020). "Automated crystal structure analysis based on blackbox optimisation" (in en). npj Computational Materials 6 (1): 75. doi:10.1038/s41524-020-0330-9. ISSN 2057-3960. https://www.nature.com/articles/s41524-020-0330-9.

- ↑ 15.0 15.1 Tamura, Ryo; Sumita, Masato; Terayama, Kei; Tsuda, Koji; Izumi, Fujio; Matsushita, Yoshitaka (31 December 2022). "Automatic Rietveld refinement by robotic process automation with RIETAN-FP" (in en). Science and Technology of Advanced Materials: Methods 2 (1): 435–444. doi:10.1080/27660400.2022.2146470. ISSN 2766-0400. https://www.tandfonline.com/doi/full/10.1080/27660400.2022.2146470.

- ↑ Chakraborti, N. (1 June 2004). "Genetic algorithms in materials design and processing" (in en). International Materials Reviews 49 (3-4): 246–260. doi:10.1179/095066004225021909. ISSN 0950-6608. http://www.tandfonline.com/doi/full/10.1179/095066004225021909.

- ↑ Patra, Tarak K.; Meenakshisundaram, Venkatesh; Hung, Jui-Hsiang; Simmons, David S. (13 February 2017). "Neural-Network-Biased Genetic Algorithms for Materials Design: Evolutionary Algorithms That Learn" (in en). ACS Combinatorial Science 19 (2): 96–107. doi:10.1021/acscombsci.6b00136. ISSN 2156-8952. https://pubs.acs.org/doi/10.1021/acscombsci.6b00136.

- ↑ M. Dieb, Thaer; Ju, Shenghong; Yoshizoe, Kazuki; Hou, Zhufeng; Shiomi, Junichiro; Tsuda, Koji (31 December 2017). "MDTS: automatic complex materials design using Monte Carlo tree search" (in en). Science and Technology of Advanced Materials 18 (1): 498–503. doi:10.1080/14686996.2017.1344083. ISSN 1468-6996. PMC PMC5532970. PMID 28804525. https://www.tandfonline.com/doi/full/10.1080/14686996.2017.1344083.

- ↑ Li, Jiawen; Zhang, Jinzhe; Tamura, Ryo; Tsuda, Koji (2022). "Self-learning entropic population annealing for interpretable materials design" (in en). Digital Discovery 1 (3): 295–302. doi:10.1039/D1DD00043H. ISSN 2635-098X. http://xlink.rsc.org/?DOI=D1DD00043H.

- ↑ Kitai, Koki; Guo, Jiang; Ju, Shenghong; Tanaka, Shu; Tsuda, Koji; Shiomi, Junichiro; Tamura, Ryo (16 March 2020). "Designing metamaterials with quantum annealing and factorization machines" (in en). Physical Review Research 2 (1): 013319. doi:10.1103/PhysRevResearch.2.013319. ISSN 2643-1564. https://link.aps.org/doi/10.1103/PhysRevResearch.2.013319.

- ↑ Koshikawa, Ami S.; Ohzeki, Masayuki; Kadowaki, Tadashi; Tanaka, Kazuyuki (15 June 2021). "Benchmark Test of Black-box Optimization Using D-Wave Quantum Annealer" (in en). Journal of the Physical Society of Japan 90 (6): 064001. doi:10.7566/JPSJ.90.064001. ISSN 0031-9015. https://journals.jps.jp/doi/10.7566/JPSJ.90.064001.

- ↑ Izawa, Syun; Kitai, Koki; Tanaka, Shu; Tamura, Ryo; Tsuda, Koji (21 April 2022). "Continuous black-box optimization with an Ising machine and random subspace coding" (in en). Physical Review Research 4 (2): 023062. doi:10.1103/PhysRevResearch.4.023062. ISSN 2643-1564. https://link.aps.org/doi/10.1103/PhysRevResearch.4.023062.

- ↑ King, Ross D.; Rowland, Jem; Oliver, Stephen G.; Young, Michael; Aubrey, Wayne; Byrne, Emma; Liakata, Maria; Markham, Magdalena et al. (3 April 2009). "The Automation of Science" (in en). Science 324 (5923): 85–89. doi:10.1126/science.1165620. ISSN 0036-8075. https://www.science.org/doi/10.1126/science.1165620.

- ↑ Boyd, James (18 January 2002). "Robotic Laboratory Automation" (in en). Science 295 (5554): 517–518. doi:10.1126/science.295.5554.517. ISSN 0036-8075. https://www.science.org/doi/10.1126/science.295.5554.517.

- ↑ Olsen, Kevin (1 December 2012). "The First 110 Years of Laboratory Automation: Technologies, Applications, and the Creative Scientist" (in en). SLAS Technology 17 (6): 469–480. doi:10.1177/2211068212455631. https://linkinghub.elsevier.com/retrieve/pii/S247263032201706X.

- ↑ Macarron, Ricardo; Banks, Martyn N.; Bojanic, Dejan; Burns, David J.; Cirovic, Dragan A.; Garyantes, Tina; Green, Darren V. S.; Hertzberg, Robert P. et al. (1 March 2011). "Impact of high-throughput screening in biomedical research" (in en). Nature Reviews Drug Discovery 10 (3): 188–195. doi:10.1038/nrd3368. ISSN 1474-1776. https://www.nature.com/articles/nrd3368.

- ↑ MacLeod, B. P.; Parlane, F. G. L.; Morrissey, T. D.; Häse, F.; Roch, L. M.; Dettelbach, K. E.; Moreira, R.; Yunker, L. P. E. et al. (15 May 2020). "Self-driving laboratory for accelerated discovery of thin-film materials" (in en). Science Advances 6 (20): eaaz8867. doi:10.1126/sciadv.aaz8867. ISSN 2375-2548. PMC PMC7220369. PMID 32426501. https://www.science.org/doi/10.1126/sciadv.aaz8867.

- ↑ Shimizu, Ryota; Kobayashi, Shigeru; Watanabe, Yuki; Ando, Yasunobu; Hitosugi, Taro (1 November 2020). "Autonomous materials synthesis by machine learning and robotics" (in en). APL Materials 8 (11): 111110. doi:10.1063/5.0020370. ISSN 2166-532X. https://pubs.aip.org/apm/article/8/11/111110/569817/Autonomous-materials-synthesis-by-machine-learning.

- ↑ Dave, Adarsh; Mitchell, Jared; Kandasamy, Kirthevasan; Wang, Han; Burke, Sven; Paria, Biswajit; Póczos, Barnabás; Whitacre, Jay et al. (1 December 2020). "Autonomous Discovery of Battery Electrolytes with Robotic Experimentation and Machine Learning" (in en). Cell Reports Physical Science 1 (12): 100264. doi:10.1016/j.xcrp.2020.100264. https://linkinghub.elsevier.com/retrieve/pii/S2666386420302861.

- ↑ Burger, Benjamin; Maffettone, Phillip M.; Gusev, Vladimir V.; Aitchison, Catherine M.; Bai, Yang; Wang, Xiaoyan; Li, Xiaobo; Alston, Ben M. et al. (9 July 2020). "A mobile robotic chemist" (in en). Nature 583 (7815): 237–241. doi:10.1038/s41586-020-2442-2. ISSN 0028-0836. https://www.nature.com/articles/s41586-020-2442-2.

- ↑ Roch, Loïc M.; Häse, Florian; Kreisbeck, Christoph; Tamayo-Mendoza, Teresa; Yunker, Lars P. E.; Hein, Jason E.; Aspuru-Guzik, Alán (16 April 2020). Hu, Jianjun. ed. "ChemOS: An orchestration software to democratize autonomous discovery" (in en). PLOS ONE 15 (4): e0229862. doi:10.1371/journal.pone.0229862. ISSN 1932-6203. PMC PMC7161969. PMID 32298284. https://dx.plos.org/10.1371/journal.pone.0229862.

- ↑ 32.0 32.1 Motoyama, Yuichi; Tamura, Ryo; Yoshimi, Kazuyoshi; Terayama, Kei; Ueno, Tsuyoshi; Tsuda, Koji (1 September 2022). "Bayesian optimization package: PHYSBO" (in en). Computer Physics Communications 278: 108405. doi:10.1016/j.cpc.2022.108405. https://linkinghub.elsevier.com/retrieve/pii/S0010465522001242.

- ↑ 33.0 33.1 Terayama, Kei; Sumita, Masato; Tamura, Ryo; Payne, Daniel T.; Chahal, Mandeep K.; Ishihara, Shinsuke; Tsuda, Koji (2020). "Pushing property limits in materials discovery via boundless objective-free exploration" (in en). Chemical Science 11 (23): 5959–5968. doi:10.1039/D0SC00982B. ISSN 2041-6520. PMC PMC7409358. PMID 32832058. http://xlink.rsc.org/?DOI=D0SC00982B.

- ↑ Terayama, Kei; Tamura, Ryo; Nose, Yoshitaro; Hiramatsu, Hidenori; Hosono, Hideo; Okuno, Yasushi; Tsuda, Koji (8 March 2019). "Efficient construction method for phase diagrams using uncertainty sampling" (in en). Physical Review Materials 3 (3): 033802. doi:10.1103/PhysRevMaterials.3.033802. ISSN 2475-9953. https://link.aps.org/doi/10.1103/PhysRevMaterials.3.033802.

- ↑ 35.0 35.1 Matsuda, Shoichi; Nishioka, Kiho; Nakanishi, Shuji (17 April 2019). "High-throughput combinatorial screening of multi-component electrolyte additives to improve the performance of Li metal secondary batteries" (in en). Scientific Reports 9 (1): 6211. doi:10.1038/s41598-019-42766-x. ISSN 2045-2322. PMC PMC6470175. PMID 30996343. https://www.nature.com/articles/s41598-019-42766-x.

- ↑ Ong, Shyue Ping; Richards, William Davidson; Jain, Anubhav; Hautier, Geoffroy; Kocher, Michael; Cholia, Shreyas; Gunter, Dan; Chevrier, Vincent L. et al. (1 February 2013). "Python Materials Genomics (pymatgen): A robust, open-source python library for materials analysis" (in en). Computational Materials Science 68: 314–319. doi:10.1016/j.commatsci.2012.10.028. https://linkinghub.elsevier.com/retrieve/pii/S0927025612006295.

- ↑ Ward, Logan; Agrawal, Ankit; Choudhary, Alok; Wolverton, Christopher (26 August 2016). "A general-purpose machine learning framework for predicting properties of inorganic materials" (in en). npj Computational Materials 2 (1): 16028. doi:10.1038/npjcompumats.2016.28. ISSN 2057-3960. https://www.nature.com/articles/npjcompumats201628.

- ↑ "RDKit: Open-Source Cheminformatics Software". 2023. https://www.rdkit.org/.

- ↑ Ojih, Joshua; Al-Fahdi, Mohammed; Rodriguez, Alejandro David; Choudhary, Kamal; Hu, Ming (4 July 2022). "Efficiently searching extreme mechanical properties via boundless objective-free exploration and minimal first-principles calculations" (in en). npj Computational Materials 8 (1): 143. doi:10.1038/s41524-022-00836-1. ISSN 2057-3960. https://www.nature.com/articles/s41524-022-00836-1.

- ↑ Tamura, Ryo; Deffrennes, Guillaume; Han, Kwangsik; Abe, Taichi; Morito, Haruhiko; Nakamura, Yasuyuki; Naito, Masanobu; Katsube, Ryoji et al. (31 December 2022). "Machine-Learning-Based phase diagram construction for high-throughput batch experiments" (in en). Science and Technology of Advanced Materials: Methods 2 (1): 153–161. doi:10.1080/27660400.2022.2076548. ISSN 2766-0400. https://www.tandfonline.com/doi/full/10.1080/27660400.2022.2076548.

- ↑ Katsube, Ryoji; Terayama, Kei; Tamura, Ryo; Nose, Yoshitaro (1 June 2020). "Experimental Establishment of Phase Diagrams Guided by Uncertainty Sampling: An Application to the Deposition of Zn–Sn–P Films by Molecular Beam Epitaxy" (in en). ACS Materials Letters 2 (6): 571–575. doi:10.1021/acsmaterialslett.0c00104. ISSN 2639-4979. https://pubs.acs.org/doi/10.1021/acsmaterialslett.0c00104.

- ↑ Hu, Wei-Hsun; Chen, Ta-Te; Tamura, Ryo; Terayama, Kei; Wang, Siqian; Watanabe, Ikumu; Naito, Masanobu (31 December 2022). "Topological alternation from structurally adaptable to mechanically stable crosslinked polymer" (in en). Science and Technology of Advanced Materials 23 (1): 66–75. doi:10.1080/14686996.2021.2025426. ISSN 1468-6996. PMC PMC8812728. PMID 35125966. https://www.tandfonline.com/doi/full/10.1080/14686996.2021.2025426.

- ↑ Ota, Hitoshi; Shima, Kunihisa; Ue, Makoto; Yamaki, Jun-ichi (1 February 2004). "Effect of vinylene carbonate as additive to electrolyte for lithium metal anode" (in en). Electrochimica Acta 49 (4): 565–572. doi:10.1016/j.electacta.2003.09.010. https://linkinghub.elsevier.com/retrieve/pii/S0013468603007266.

- ↑ Zhang, Xue-Qiang; Cheng, Xin-Bing; Chen, Xiang; Yan, Chong; Zhang, Qiang (1 March 2017). "Fluoroethylene Carbonate Additives to Render Uniform Li Deposits in Lithium Metal Batteries" (in en). Advanced Functional Materials 27 (10): 1605989. doi:10.1002/adfm.201605989. https://onlinelibrary.wiley.com/doi/10.1002/adfm.201605989.

- ↑ Ginsbourger, D.; Janusevskis, J.; Le Riche, R. (2011). "Dealing with asynchronicity in parallel Gaussian Process based global optimization". Mines Saint-Etienne. https://hal.science/hal-00507632.

- ↑ Janusevskis, Janis; Le Riche, Rodolphe; Ginsbourger, David; Girdziusas, Ramunas (2012), Hamadi, Youssef; Schoenauer, Marc, eds., "Expected Improvements for the Asynchronous Parallel Global Optimization of Expensive Functions: Potentials and Challenges", Learning and Intelligent Optimization (Berlin, Heidelberg: Springer Berlin Heidelberg) 7219: 413–418, doi:10.1007/978-3-642-34413-8_37, ISBN 978-3-642-34412-1, http://link.springer.com/10.1007/978-3-642-34413-8_37. Retrieved 2023-09-18

Notes

This presentation is faithful to the original, with only a few minor changes to presentation. In some cases important information was missing from the references, and that information was added. In the original, there are multiple instances of citing research work using the last name of the last author listed, rather than the last name of the first author listed; this may have been a product of Japanese culture tending to read text from right to left. For this version, the last name of the first author was used to be consistent with research norms.