Difference between revisions of "Journal:Can a byte improve our bite? An analysis of digital twins in the food industry"

Shawndouglas (talk | contribs) (Saving and adding more.) |

Shawndouglas (talk | contribs) (Saving and adding more.) |

||

| Line 111: | Line 111: | ||

==Methodology== | ==Methodology== | ||

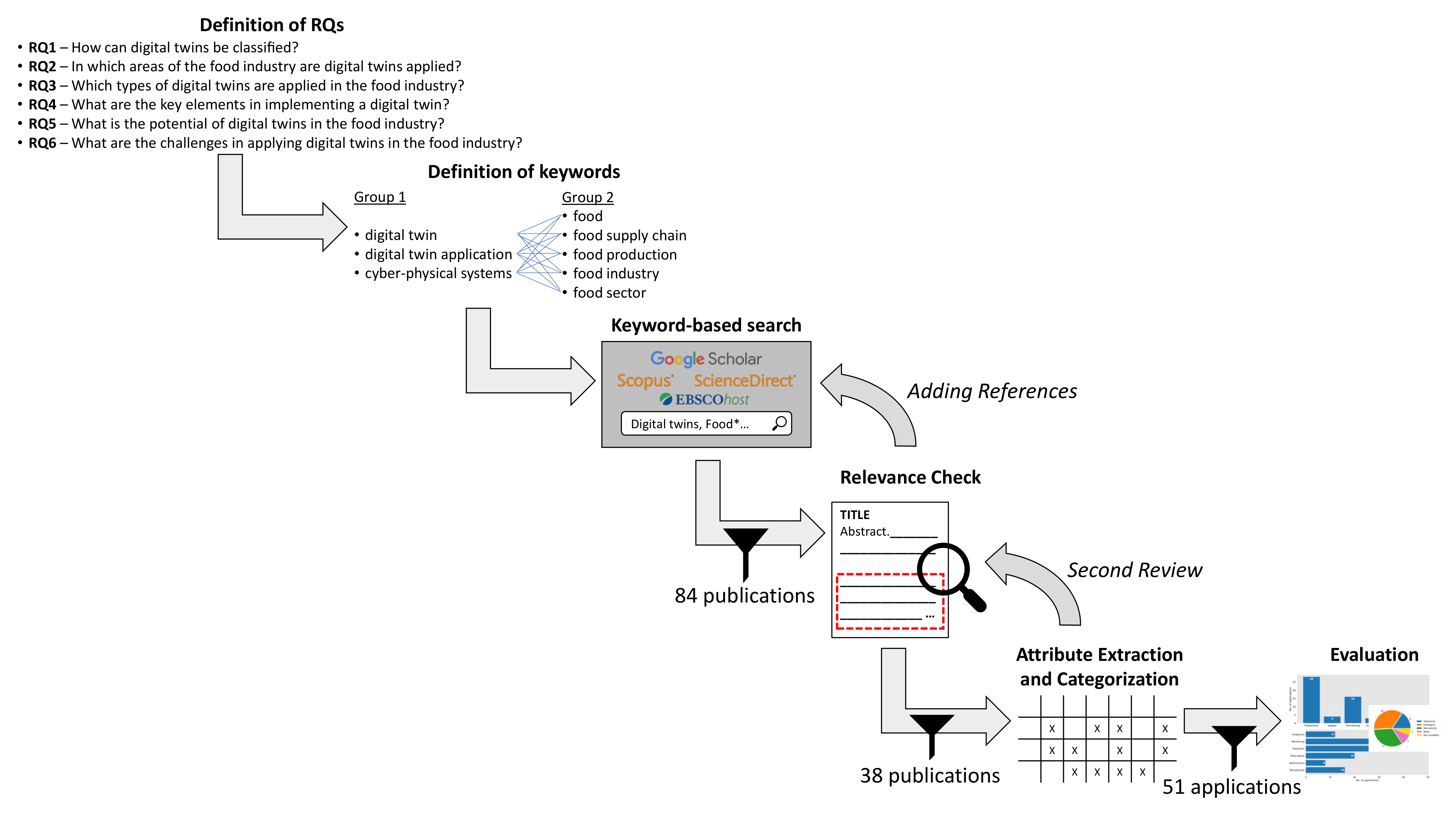

The methodology for the survey integrates methods from the guidelines of Webster and Watson [37] for a structured literature review, and Petersen ''et al.'' [38] for systematic mapping studies. The research is based on the steps shown in Figure 3. In the beginning, we framed our aim in the form of research questions. We defined exclusion and inclusion criteria and performed keyword-based searches for filtering the articles based on their titles and abstracts. The search method was adapted from Webster and Watson [37] to cover a wide range of publications with regards to regions, fields, and publishers. After identifying the set of possible relevant publications, a relevance analysis based on a full paper screening was performed. Subsequently, descriptions and properties of the digital twin applications, as well as bibliography data, have been extracted and classified as proposed by Petersen ''et al.'' [38] In the following, we describe these steps in detail. | |||

[[File:Fig3 Henrichs Sensors22 22-1.png|1200px]] | |||

{{clear}} | |||

{| | |||

| style="vertical-align:top;" | | |||

{| border="0" cellpadding="5" cellspacing="0" width="1200px" | |||

|- | |||

| style="background-color:white; padding-left:10px; padding-right:10px;" |<blockquote>'''Figure 3.''' Overview of the methodology for the classification in this survey. Publications found through a keyword-based search were first selected based on the title and abstract. Afterward, the publications were analyzed, and relevant publications were categorized in a previously defined taxonomy.</blockquote> | |||

|- | |||

|} | |||

|} | |||

===Definition of research questions=== | |||

The primary aim of this work is (i) to provide an overview of digital twins applied in the food sector regarding their intended use and (ii) to identify future research areas. According to this goal, we derived our research questions. First, we searched for taxonomies (RQ1) that enable classifying the digital twin concepts that we found according to their application purpose. As we are primarily interested in which area of the food industry (i.e., stages of the FSC) digital twins are applied, we decided to assign the applications found to the stages of the FSC as presented in Figure 1 (RQ2). To better understand the application’s reason for use, we classified the applications found according to our taxonomy (see RQ1) to answer the research question of how a digital twin can support the activities in the FSC (RQ3). Further, we analyzed the different types of digital twins that we identified for providing an overview of the different key elements of a digital twin in the FSC (RQ4). Aiming to show the applicability and the benefits of implementing digital twins in different stages of the FSC, we conducted the final research questions. At first, we discussed the potential of digital twins to improve the food industry (RQ5). Then, we discussed the challenges of implementing digital twins in the food sector (RQ6). These considerations led to the following research questions: | |||

* '''RQ1''' — How can digital twins be classified? | |||

* '''RQ2''' — In which areas of the food industry are digital twins applied? | |||

* '''RQ3''' — Which types of digital twins are applied in the food industry? | |||

* '''RQ4''' — What are the key elements in implementing a digital twin? | |||

* '''RQ5''' — What is the potential of digital twins in the food industry? | |||

* '''RQ6''' — What are the challenges in applying digital twins in the food industry? | |||

===Selection method=== | |||

To find digital twin applications in the FSC (answering RQ2 and RQ3), we conducted a literature review and included publications available between May and the end of September 2021. We searched the following databases: Google Scholar, Scopus, ScienceDirect, and Academic Search Complete by EBSCO Publishing. We created two groups of keywords. The first group concerned digital twins, including the keywords “digital twin,” “digital twin application,” and “cyber–physical systems,” while the second group provided the relation to the food sector, i.e., consisted of the keywords “food,” “food supply chain,” “food production,” “food industry,” and “food sector.” The search was performed by combining each of the keywords of both groups. | |||

While we see agricultural plants or farms as part of the FSC (production stage), we did not search directly for <tt>“digital twin” AND (“agriculture” OR “agrifood”)</tt> since our main focus is on food quality as it relates to food processing. Therefore, the food processing and the transportation stages (supply and distribution), as well as the retail stage, are from special interest rather than the primary food production since the food quality parameters are ultimately adjusted during processing. After the processing stage, all actions, e.g., cooling, serve to maintain and guarantee food quality until consumption. Still, we did not discard works related to the agriculture sector when found with our set of keywords. | |||

Additionally, we added publications to our list—which we did not find directly but rather were referred to by other publications and possibly relevant—for this research (backward search). In the literature search process, we also identified applicable literature reviews. [29,39,40,41] However, as we wanted to avoid the misinterpretation or incorrect reproduction of information, we rather included the original publications or sources of such reviews. This ensured that we did not include different points of view for the same application. | |||

Furthermore, we performed a free web search with Google and DuckDuckGo to find examples for digital twins related to the FSC applied in the industry. While this search provided many results, we only included a few of them [42,43,44,45,46,47], as the found information was often not precise enough to analyze in the detail required for a classification within our taxonomy. | |||

===Analysis method=== | |||

Revision as of 19:39, 21 November 2022

| Full article title | Can a byte improve our bite? An analysis of digital twins in the food industry |

|---|---|

| Journal | Sensors |

| Author(s) | Henrichs, Elia; Noack, Tanja; Piedrahita, Ana María Pinzon; Salem, María Alejandra; Stolz, Johnathan; Krupitzer, Christian |

| Author affiliation(s) | University of Hohenheim |

| Primary contact | christian dot krupitzer at uni-hohenheim dot de |

| Editors | Tiwari, Ashutosh |

| Year published | 2022 |

| Volume and issue | 22(1) |

| Article # | 115 |

| DOI | 10.3390/s22010115 |

| ISSN | 1424-8220 |

| Distribution license | Creative Commons Attribution 4.0 International |

| Website | https://www.mdpi.com/1424-8220/22/1/115/htm |

| Download | https://www.mdpi.com/1424-8220/22/1/115/pdf (PDF) |

|

|

This article should be considered a work in progress and incomplete. Consider this article incomplete until this notice is removed. |

Abstract

The food industry faces many challenges, including the need to feed a growing population, manage food loss and waste, and improve inefficient production systems. To cope with those challenges, digital twins—digital representations of physical entities created by integrating real-time and real-world data—seem to be a promising approach. This paper aims to provide an overview of digital twin applications in the food industry and analyze their challenges and potentials. First, a literature review is executed to examine digital twin applications in the food supply chain. The applications found are classified according to a taxonomy, and key elements to implement digital twins are identified. Further, the challenges and potentials of digital twin applications in the food industry are discussed. This survey reveals that application of digital twins mainly target the production (i.e., agriculture) or food processing stages. Nearly all applications are used for monitoring and many for prediction. However, relatively few focus on the integration of digital twins in systems for developing autonomous control or providing recommendations to humans. The main challenges of implementing digital twins are combining multidisciplinary knowledge and providing enough data. Nevertheless, digital twins provide huge potentials, e.g., in determining food quality, ensuring traceability, or designing personalized foods.

Keywords: digital twins, food industry, food supply chain, cyber–physical systems, sensors, internet of things, survey

Introduction

With the evolution and digitalization towards Industry 4.0, the concept of creating digital copies of physical systems received entry to the industry. [1] In particular, the food industry is of special interest because it requires highly efficient use of available resources. [2] Over time, food production systems have evolved alongside technological innovations, allowing for increased production, greater product variety, more resilient food stocks, and increased international trade. Yet, despite these advances, food systems around the world continue to face unprecedented challenges that pose significant threats to current food systems, such as climate change, pressure to feed a growing global population, and persistent global food waste. In addition, there are growing societal demands for greater food provenance, traceability, and sustainability within the food system. [3]

A key element of Industry 4.0 is the digital twin, a virtual model of a product, process, or system created with data collected by sensors that enables simulations or real-time analyses of that product, process, or system. [1,4] The use of digital twins seems beneficial in food processing for various reasons. The COVID-19 pandemic demonstrated the vulnerability of food supply resilience. [5] To ensure the consistency of a food supply, production processes must allow high flexibility and adaptivity. [6] Furthermore, product quality is influenced by different quality levels of input materials. Especially in the case of seasonal fluctuations impacting raw material quality, the ability to adjustment parameters in the production process is essential. Introduction processes of new products could be simplified by a digital twin of already existing physical processes. The digital twin is able to learn the correct process parameters for production and is used as the knowledge base within a self-adaptive software system. [7] However, a digital twin of food production has additional specific requirements compared to digital twins of the production of material goods. [8] Due to the variability of raw materials, these cannot be based only on the processing steps but must also take into account the chemical, physical, and (micro)biological properties of the food. However, when functioning as intended, the technology can be applied to create a detailed digital model of the supply chain that integrates real-time and real-world data to respond to unexpected events and uncertainty within the supply chain.

This work aims to provide an overview of digital twin applications in the food industry and analyze their challenges and potentials. We first present a taxonomy to differentiate underlying technologies and better understand the intended use of each digital twin. Second, a survey is executed to examine digital twin applications in the food supply chain (FSC). We target the FSC as it provides a link between all the key activities and processes involved in bringing a specific food product to market. [9] To meet these unprecedented challenges, FSCs and corresponding actors are turning to modern technology for assistance. [10] We classify the found applications of digital twins according to our taxonomy. Third, we investigate the key elements to implement digital twins in the FSC. Fourth, since the concept of digital twins is still young, we discuss the potentials of applying them in the food sector. Finally, we discuss the challenges of applying digital twins in the food industry.

In summary, this paper contributes to the body of research by providing the following scopes:

- Classification of digital twins in the food sector,

- Overview of the application of digital twins in the food industry,

- Definition of the key elements for implementing a digital twin,

- Analysis of the potential of digital twins in the food industry, and

- Description of challenges of applying digital twins in the food industry.

The remainder of the paper is structured as follows. The next section explains several fundamentals related to the FSC and the digitalization of the food industry, and it provides a definition of digital twins. Then, the methodological approach for the literature review is presented. The subsequent section evaluates the literature review results and summarizes the key elements for implementing digital twins. Then we discuss the potentials and challenges of digital twins and their implementation in the food supply chain, and then we discriminate this work against other publications in the field. We conclude this paper with a summary of our results.

Background

The food supply chain

A supply chain (SC) is a network of actors structured around activities and processes that aim to satisfy given consumer demand by bringing products or services to market. [11] This network includes feedback and circular economy aspects, e.g., for sustainability reasons such as with the recycling of materials. [12] The actors within the SC are linked through upstream or downstream processes and activities that produce value in the form of finished products or services. [11] In the same sense, a FSC encompasses all activities involved in the creation and transformation of raw materials into food products, as well as their retail and consumption. [10] However, FSCs do differ significantly from other SCs due to the complexity of producing, transporting, and managing food products. [13]

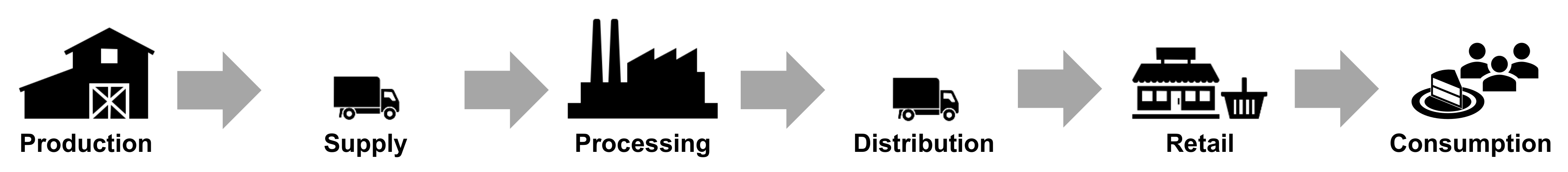

While it is important to consider not only the primary flow but also the tangential and secondary flows that are contained within the FSC—as these are opportunities to reduce food loss and waste through reuse and recycling [12]—we focus on a simplified, linear, and straight-forward structure of the FSC. This is sufficient for this survey since the focus is on single activities of the FSC that are present identically in the simplified FSC as well as in a circular view. Figure 1 provides an overview of the FSC and the main actors, to which the digital twin applications will be assigned. Commonly, the FSC begins with production (which usually involves an agricultural farm) and continues with supply, processing, distribution, and retail, finally ending with consumption.

|

Worth mentioning is that the stages could be thereby divided into several processing or transportation sub-entities. For instance, Shoji et al. [14] investigate the cold chain of fruits and vegetables from a (farm to) packhouse to distribution to the retailer. The authors divide the transportation steps between the supply from packhouse to distribution center and from distribution center to the retailer. In our understanding, the packhouse would be part of the processing stage, and both the transportation and the distribution would be summarized as distribution.

It is crucial for SCs to be designed with consideration for uncertainty and risk, as mitigation measures and solutions must be developed to prevent disruptions to the SC. [9] Those disruptions impact the SC’s regular flow and affect the other actors directly. [15] In particular, the most frequent FSC disruptions are human error, communication misunderstandings, organizational process errors, and quality problems with goods received. [16] Consequently, disruptions may result in negative effects to the final product [9] regarding sustainability, safety, and quality. [13]

Additionally, several challenges in the FSC occur during different stages. This includes [17]:

- Production estimation and optimization in the production stage, including crop management and security, as well as livestock control;

- Production planning in the processing stage, regarding the post-harvest loss, as well as demand prediction;

- Distribution management concerning route planning, prediction of SC risks and disruptions, and shelf life prediction; and

- Consumption, which represents consumer behavior, their dietary behavior, food loss and waste, and the prediction of daily demand.

The concept of Industry 4.0 is associated with the fourth industrial revolution. It combines technologies such as cyber–physical systems (CPSs), internet of things (IoT), and cloud computing. While the term "Industry 4.0" is primarily used in Europe, a similar concept—the industrial internet of things (IIoT)—mainly used in the US describes advances in big data, cloud computing, and networking of machinery and systems in the industrial sector. [18] Based on CPSs and IoT, manufacturing processes including logistics (i.e., SC management), services, and maintenance are efficiently synchronized within in Industry 4.0. [19] Hence, Industry 4.0 does not focus on a single process or technology but integrates all processes, resulting in a highly flexible and integrated, optimized manufacturing process. The complete implementation of Industry 4.0 or IIoT culminates in the smart factory, an integrated production process that is entirely self-organizing by the connected machines and intelligent software without any human interaction. [20]

Further, modern FSCs increasingly make use of integrated information and communication technology (ICT) systems to assist with mitigating against uncertainty and risk, process optimization, and numerous other applications. [11] In addition, ICT systems are of particular interest for traceability and decision-making functions within the FSC. [21] Traceability is important to identify quality and safety concerns and to ensure food provenance to the consumer and authorities. [13] As described by Zhong et al. [9], traceability systems in FSCs vary greatly depending on region, government regulations, and digitalization of the FSC. ICT systems as digital twins are able to assist with decision-making, collaboration, scheduling and planning, logistics management, and warehouse management within the FSC. [22]

A definition of "digital twin"

The concept of digital twins first came up during NASA’s Apollo 13 mission in 1970, as the ground team used simulators to provide solutions to the spacecraft crew for landing them safely. [23] The term “digital twin” was first used and defined in 2003. [24] This concept contains a physical object and a virtual object, connecting data and information from both. NASA formalized the description of digital twins in 2012 and forecasted its potential in the aerospace sector. [25] Here, the digital twin is defined as a multi-physics and multi-scale simulation of a vehicle or system, which uses the best physical models, sensor data, and history, resulting in a mirror of the physical counterpart. The discovery that digital twins might be used in a variety of industries other than aerospace accelerated its development [26]; in particular, it is an important concept for Industry 4.0 and IIoT.

For purposes of this work, we follow the definition of a digital twin provided by the CIRP Encyclopedia of Production Engineering [27]:

A digital twin is a digital representation of an active unique product (real device, object, machine, service, or intangible asset) or unique product-service system (a system consisting of a product and a related service) that comprises its selected characteristics, properties, conditions, and behaviors by means of models, information, and data within a single or even across multiple life cycle phases.

As such, a digital twin virtually represents its real-world counterpart, containing all its essential properties. [8] It is based on real-world comprehensive data measurements, which form the digital profile of the physical object or process. Consequently, a digital twin is connected to the real-world object or system through a continuously updated data flow. [28] Further, the digital twin is able to simulate the relevant processes and kinetics accurately. [8] In this sense, a digital twin may be seen as an ever-evolving digital profile of the past, current, and even future behavior of a process or a physical object and allow the prediction of uncertainty in the process steps. [28]

Defraeye et al. [8] define three common principles to a digital twin. Firstly, it must contain all the necessary components and material properties of what it is representing. Secondly, it can reliably and accurately simulate all relevant processes through the product life cycle. Finally, the digital twin should be connected with its real-world counterpart, as this differs a digital twin from simpler models. Communication is preferred to be realized in real-time, but the data could also flow offline.

These principles are in accordance with Jones et al. [29], who define twinning as the synchronization of the states of the physical and virtual entities. Additionally, the virtual model consists of high fidelity. Bottani et al. [30] expand upon this, explaining that a digital twin is more than the representation of the physical counterpart, since the goal of a digital twin is to replicate all behaviors and relationships of a system and its environment.

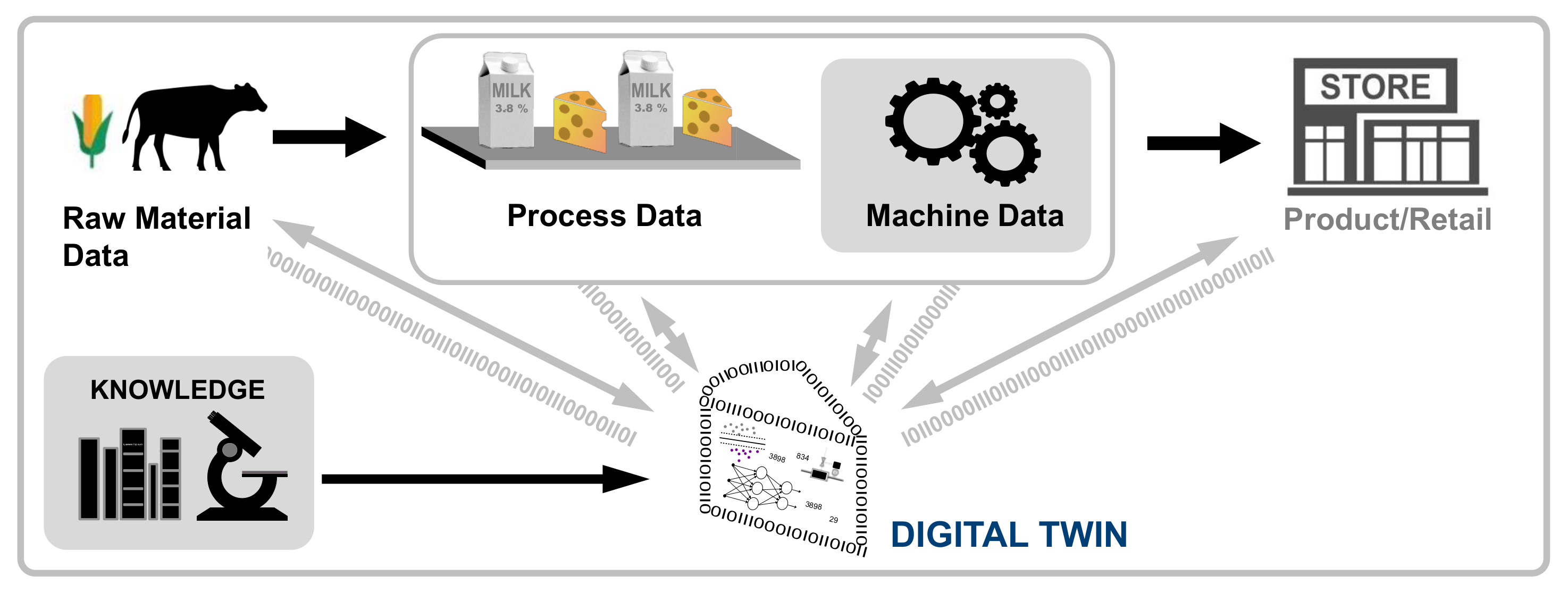

Further, five technological components enable digital twins [28]: sensors, integration capabilities, real-world aggregated data, analytical techniques, and actuators. Those technologies are required to aggregate the different available data sources (mainly related to the product and the process) into one comprehensible model of the digital twin, as well as support the prediction or analysis with a digital twin. Figure 2 presents the diversity of potential data resources for a food-based digital twin.

|

A concept closely related to digital twins are CPSs. [31,32] While a digital twin is a digital copy of a product or physical system with the intention of performing real-time optimization, a CPS merges computational and physical processes to seamlessly support humans with intelligence when using machines. [33] CPSs often include digital twins as a base for their decision-making processes. [34,35,36]

Methodology

The methodology for the survey integrates methods from the guidelines of Webster and Watson [37] for a structured literature review, and Petersen et al. [38] for systematic mapping studies. The research is based on the steps shown in Figure 3. In the beginning, we framed our aim in the form of research questions. We defined exclusion and inclusion criteria and performed keyword-based searches for filtering the articles based on their titles and abstracts. The search method was adapted from Webster and Watson [37] to cover a wide range of publications with regards to regions, fields, and publishers. After identifying the set of possible relevant publications, a relevance analysis based on a full paper screening was performed. Subsequently, descriptions and properties of the digital twin applications, as well as bibliography data, have been extracted and classified as proposed by Petersen et al. [38] In the following, we describe these steps in detail.

|

Definition of research questions

The primary aim of this work is (i) to provide an overview of digital twins applied in the food sector regarding their intended use and (ii) to identify future research areas. According to this goal, we derived our research questions. First, we searched for taxonomies (RQ1) that enable classifying the digital twin concepts that we found according to their application purpose. As we are primarily interested in which area of the food industry (i.e., stages of the FSC) digital twins are applied, we decided to assign the applications found to the stages of the FSC as presented in Figure 1 (RQ2). To better understand the application’s reason for use, we classified the applications found according to our taxonomy (see RQ1) to answer the research question of how a digital twin can support the activities in the FSC (RQ3). Further, we analyzed the different types of digital twins that we identified for providing an overview of the different key elements of a digital twin in the FSC (RQ4). Aiming to show the applicability and the benefits of implementing digital twins in different stages of the FSC, we conducted the final research questions. At first, we discussed the potential of digital twins to improve the food industry (RQ5). Then, we discussed the challenges of implementing digital twins in the food sector (RQ6). These considerations led to the following research questions:

- RQ1 — How can digital twins be classified?

- RQ2 — In which areas of the food industry are digital twins applied?

- RQ3 — Which types of digital twins are applied in the food industry?

- RQ4 — What are the key elements in implementing a digital twin?

- RQ5 — What is the potential of digital twins in the food industry?

- RQ6 — What are the challenges in applying digital twins in the food industry?

Selection method

To find digital twin applications in the FSC (answering RQ2 and RQ3), we conducted a literature review and included publications available between May and the end of September 2021. We searched the following databases: Google Scholar, Scopus, ScienceDirect, and Academic Search Complete by EBSCO Publishing. We created two groups of keywords. The first group concerned digital twins, including the keywords “digital twin,” “digital twin application,” and “cyber–physical systems,” while the second group provided the relation to the food sector, i.e., consisted of the keywords “food,” “food supply chain,” “food production,” “food industry,” and “food sector.” The search was performed by combining each of the keywords of both groups.

While we see agricultural plants or farms as part of the FSC (production stage), we did not search directly for “digital twin” AND (“agriculture” OR “agrifood”) since our main focus is on food quality as it relates to food processing. Therefore, the food processing and the transportation stages (supply and distribution), as well as the retail stage, are from special interest rather than the primary food production since the food quality parameters are ultimately adjusted during processing. After the processing stage, all actions, e.g., cooling, serve to maintain and guarantee food quality until consumption. Still, we did not discard works related to the agriculture sector when found with our set of keywords.

Additionally, we added publications to our list—which we did not find directly but rather were referred to by other publications and possibly relevant—for this research (backward search). In the literature search process, we also identified applicable literature reviews. [29,39,40,41] However, as we wanted to avoid the misinterpretation or incorrect reproduction of information, we rather included the original publications or sources of such reviews. This ensured that we did not include different points of view for the same application.

Furthermore, we performed a free web search with Google and DuckDuckGo to find examples for digital twins related to the FSC applied in the industry. While this search provided many results, we only included a few of them [42,43,44,45,46,47], as the found information was often not precise enough to analyze in the detail required for a classification within our taxonomy.

Analysis method

References

Notes

This presentation is faithful to the original, with only a few minor changes to presentation and updates to spelling and grammar. In some cases important information was missing from the references, and that information was added.