Difference between revisions of "Journal:NIMS-OS: An automation software to implement a closed loop between artificial intelligence and robotic experiments in materials science"

Shawndouglas (talk | contribs) (Saving and adding more.) |

Shawndouglas (talk | contribs) (Saving and adding more.) |

||

| Line 19: | Line 19: | ||

|download = [https://www.tandfonline.com/doi/pdf/10.1080/27660400.2023.2232297?download=true https://www.tandfonline.com/doi/pdf/10.1080/27660400.2023.2232297] (PDF) | |download = [https://www.tandfonline.com/doi/pdf/10.1080/27660400.2023.2232297?download=true https://www.tandfonline.com/doi/pdf/10.1080/27660400.2023.2232297] (PDF) | ||

}} | }} | ||

{{Ombox math}} | |||

{{ombox | {{ombox | ||

| type = notice | | type = notice | ||

| Line 26: | Line 27: | ||

}} | }} | ||

==Abstract== | ==Abstract== | ||

NIMS-OS (NIMS Orchestration System) is a [[Python (programming language)|Python]] library created to realize a closed loop of [[Laboratory automation|robotic]] experiments and [[artificial intelligence]] (AI) without human intervention for automated [[Materials science|materials exploration]]. It uses various combinations of modules to operate autonomously. Each module acts as an AI for materials exploration or a controller for a robotic experiments. As AI techniques, | NIMS-OS (NIMS Orchestration System) is a [[Python (programming language)|Python]] library created to realize a closed loop of [[Laboratory automation|robotic]] experiments and [[artificial intelligence]] (AI) without human intervention for automated [[Materials science|materials exploration]]. It uses various combinations of modules to operate autonomously. Each module acts as an AI for materials exploration or a controller for a robotic experiments. As AI techniques, Optimization Tools for PHYSics Based on Bayesian Optimization (PHYSBO), BoundLess Objective-free eXploration (BLOX), phase diagram construction (PDC), and random exploration (RE) methods can be used. Moreover, a system called NIMS Automated Robotic Electrochemical Experiments (NAREE) is available as a set of robotic experimental equipment. [[Data visualization|Visualization tools]] for the results are also included, which allows users to check the optimization results in real time. Newly created modules for AI and robotic experiments can be added easily to extend the functionality of the system. In addition, we developed a graphical user interface (GUI)-driven application to control NIMS-OS. To demonstrate the operation of NIMS-OS, we consider an automated exploration for new electrolytes. NIMS-OS is available at [https://github.com/nimsos-dev/nimsos https://github.com/nimsos-dev/nimsos]. | ||

'''Keywords''': NIMS-OS, robotic experiments, artificial intelligence, electrochemistry, materials informatics | '''Keywords''': NIMS-OS, robotic experiments, artificial intelligence, electrochemistry, materials informatics | ||

==Introduction== | ==Introduction== | ||

The integration of | The integration of robotic experiments and [[artificial intelligence]] (AI) is essential to realize automated materials exploration. If an AI system can take on some [[information]] tasks conventionally performed by human researchers, robotic systems can then execute the required physical tasks and experiments for materials exploration can proceed automatically. Such a platform may be expected to discover many novel materials and lead to substantial innovation in [[materials science]]. In recent years, significant progress has been made in the development of AI techniques and robotic devices suitable for materials exploration. | ||

Since the launch of the Materials Genome Initiative [1], AI techniques have been actively used for materials exploration. [2–4] In general, materials exploration can be regarded as the problem of finding optimal materials from among a materials search space. The elements to be used in the search space must be configured, along with its composition range, process parameter range, and so forth. To solve this problem, black-box optimization methods are useful [5], and various methods have been developed and applied to fit various needs. Bayesian optimization (BO) is among the most frequently used methods in materials science. [6–8]. In this method, promising materials can be selected in the materials search space using the predictions of their properties and the uncertainty of these predictions evaluated by Gaussian process regression. Using BO, various real materials, such as Li-ion conductive materials [9], multilayered metamaterials [10], halide perovskite [11], superalloys [12], and electrolytes [13] have been explored. BO is also used for the automated analysis of materials [14–15]. In addition, many methods have been proposed for black-box optimization in materials exploration, such as genetic algorithms [16–17], Monte Carlo tree search [18], rare event sampling [19], and algorithms using an Ising machine. [20–22] In the future, many more innovative methods are expected to be developed. | Since the launch of the Materials Genome Initiative [1], AI techniques have been actively used for materials exploration. [2–4] In general, materials exploration can be regarded as the problem of finding optimal materials from among a materials search space. The elements to be used in the search space must be configured, along with its composition range, process parameter range, and so forth. To solve this problem, black-box optimization methods are useful [5], and various methods have been developed and applied to fit various needs. Bayesian optimization (BO) is among the most frequently used methods in materials science. [6–8]. In this method, promising materials can be selected in the materials search space using the predictions of their properties and the uncertainty of these predictions evaluated by Gaussian process regression. Using BO, various real materials, such as Li-ion conductive materials [9], multilayered metamaterials [10], halide perovskite [11], superalloys [12], and electrolytes [13] have been explored. BO is also used for the automated analysis of materials [14–15]. In addition, many methods have been proposed for black-box optimization in materials exploration, such as genetic algorithms [16–17], Monte Carlo tree search [18], rare event sampling [19], and algorithms using an Ising machine. [20–22] In the future, many more innovative methods are expected to be developed. | ||

Robotic experiments have progressed to realize [[laboratory automation]] of chemical analysis and high-throughput screening in the field of biology. [23–26]. Various types of automated analyzers and pipetting devices have been developed, and robotic arms have been used as a transport system to connect these systems. Moreover, robotic technology has been used to explore novel materials, such as thin-film materials [27–28], battery electrolytes [13,29], and photocatalysts. [30] These studies used BO to automate the proposal of promising experimental conditions. This enables a closed loop of robotic experiments and AI that can perform automated materials exploration without human intervention. This approach involves some key advantages, such as the ability to generate materials data of uniform [[Quality (business)|quality]] and the absence of human error. In contrast, at present, robotics systems are limited in their ability to perform complex material synthesis tasks that require the skills of experts. Thus, further innovation in robotic devices will be important. | |||

In addition to AI and robotic technologies, the control systems and software used to interlink them are also an important element to realize a closed loop without human intervention. Generally, different AI algorithms should be used depending on the motivation of a materials exploration task. Furthermore, the procedure to control the devices should depends on the nature and characteristics of the robotic systems used. Therefore, control software has thus far been developed on a case-by-case basis for different AI algorithms and robotic systems. | |||

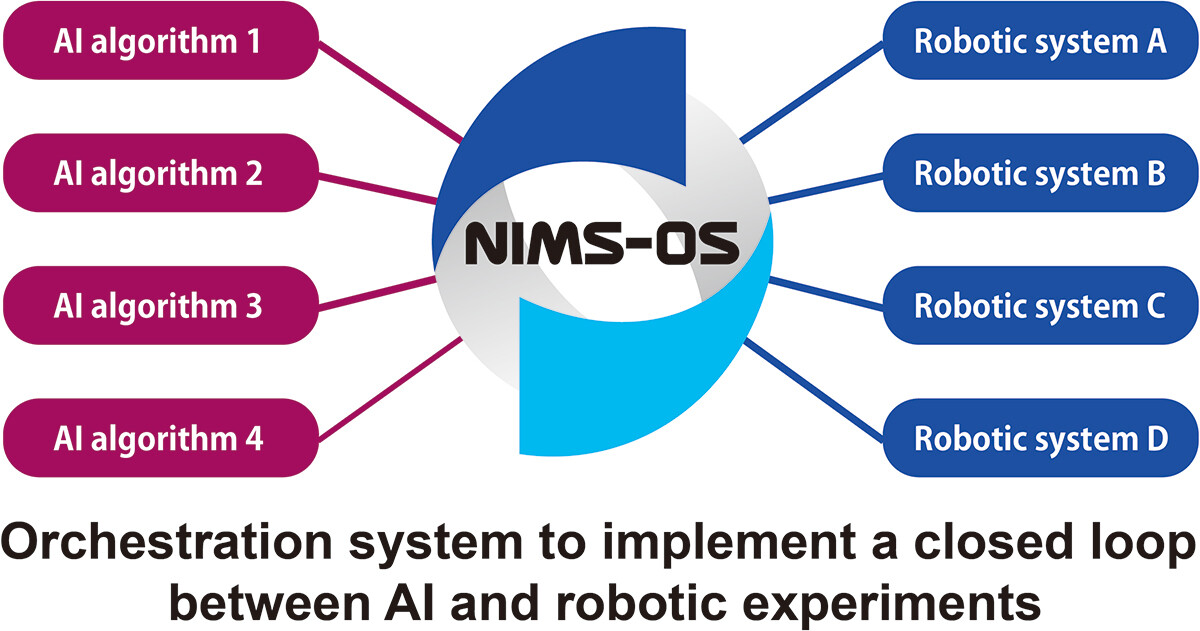

In this study, we developed NIMS-OS (NIMS Orchestration System) to realize a closed loop between AI models and robotic experiments, with the aim of establishing a generic control software system. Although this software was written in the [[Python (programming language)|Python programming language]], we also developed a graphical user interface (GUI)-driven version to improve operability after installation. NIMS-OS treats each AI algorithm and each robotic system as separate modules (see Figure 1). This enables the implementation of a closed loop with any combination of these modules. If modules for new AI algorithms or robotic systems are prepared, new closed-loop systems can be easily controlled via NIMS-OS. One of the advantages of developing such generic control software is the establishment of technical standards for automated materials exploration. For AI algorithms, we determined standard formats for the input and output. Algorithms created according to the standard format can be immediately tested using any currently available robotic system. Specifically, we developed a standard format in which all the experimental conditions to be explored are listed in advance, and the appropriate experimental conditions that have not yet been tested are selected from the list by AI algorithms. The advantage of this approach is that it enables automated materials exploration utilizing materials databases. When utilizing materials databases, the compositional and structural information needs to be converted into materials descriptors, which serve as the materials search space. However, this search space generated from the materials databases cannot be solely defined by a continuous parameter space, and it requires a selection from the pre-listed descriptors. Of course, optimization of continuous parameters can still be handled approximately by preparing a list of grid points that discretize the continuous parameters. Furthermore, we expect this work to contribute to the development of new AI algorithms for automated materials exploration. For robotic systems, we expect modules developed based on NIMS-OS to increase the commonality of operational procedures, leading to cost reductions as new robotic experimental devices are introduced. Note that ChemOS [31] is similar to NIMS-OS; it was developed as an automation system in the field of chemistry. ChemOS specializes in BO within a defined continuous or discretized parameter space and includes several default modules for various BO methods. On the other hand, NIMS-OS offers the capability to perform automated materials explorations not only within a defined parameter space but also utilizing materials databases. In addition to BO, NIMS-OS also incorporates several default implementations of black-box optimization methods to deal with different motivations in materials explorations. | |||

[[File:Fig1 Tamura SciTechAdvMatMeth2023 3-1.jpeg|700px]] | |||

{{clear}} | |||

{| | |||

| style="vertical-align:top;" | | |||

{| border="0" cellpadding="5" cellspacing="0" width="700px" | |||

|- | |||

| style="background-color:white; padding-left:10px; padding-right:10px;" |<blockquote>'''Figure 1.''' Image of the combinations of AI algorithms and robotic systems via NIMS-OS.</blockquote> | |||

|- | |||

|} | |||

|} | |||

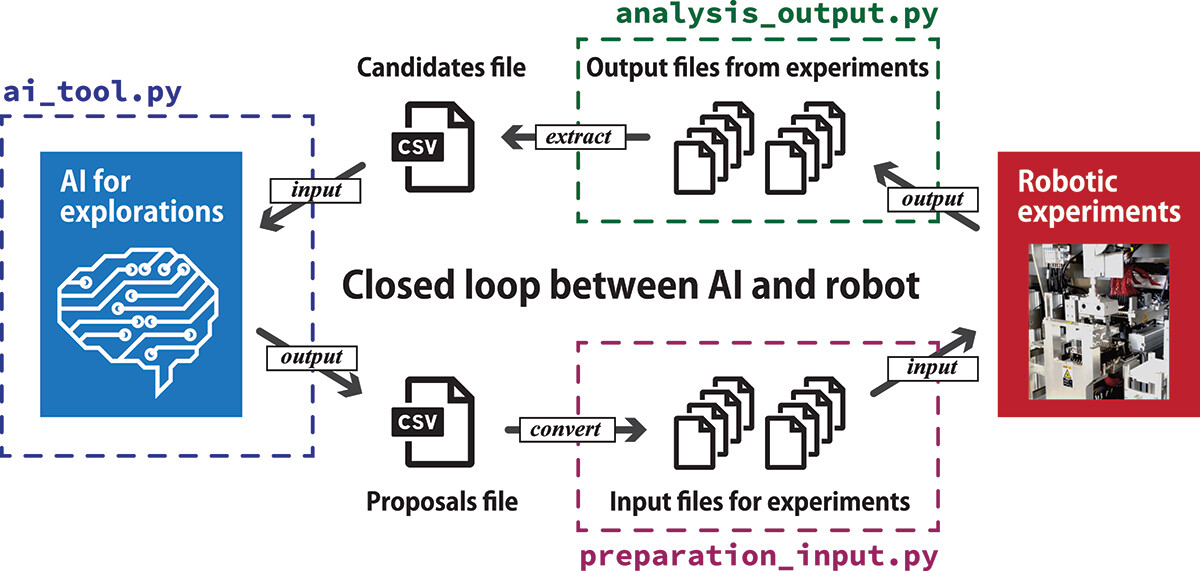

Let us briefly introduce the specifications of NIMS-OS. First, a candidates file listing experimental conditions as a materials search space should be prepared in advance. A closed loop is formed according to the following three steps (see Figure 2): | |||

* Step 1: Select promising experimental conditions from the candidates file using an AI model. | |||

* Step 2: Create an input file for the robotic experiments and execute the experiments. | |||

* Step 3: Analyze the output from the experiments and update the candidates file based on the experimental results. | |||

[[File:Fig2 Tamura SciTechAdvMatMeth2023 3-1.jpeg|700px]] | |||

{{clear}} | |||

{| | |||

| style="vertical-align:top;" | | |||

{| border="0" cellpadding="5" cellspacing="0" width="700px" | |||

|- | |||

| style="background-color:white; padding-left:10px; padding-right:10px;" |<blockquote>'''Figure 2.''' Procedures in NIMS-OS and roles of each Python scripts.</blockquote> | |||

|- | |||

|} | |||

|} | |||

Currently, the following AI algorithms are used as modules, which are available for Step 1: (i) Optimization Tools for PHYSics Based on Bayesian Optimization (PHYSBO) [32], (ii) BoundLess Objective-free eXploration (BLOX) [33], and (iii) phase diagram construction (PDC) [34] methods, with the random exploration (RE) approach able to be selected according to the purpose of materials exploration effort. For Steps 2 and 3, a STANdard module (STAN) is provided for robotic experiments, which enables operation checks even without devices, along with a module for NIMS Automated Robotic Electrochemical Experiments (NAREE) [13,35]. We plan to continue developing additional modules for this system. | |||

The reminder of this study is organized as follows. The next section describes the preparation of a candidates file storing experimental conditions, followed by an introduction to the available modules for the AI and robotic experiments in NIMS-OS. Then the use of the Python code, and the usage of the GUI version is explained. As a demonstration, the results of an autonomous electrolyte exploration via a closed-loop approach using PHYSBO and NAREE in NIMS-OS are described. Finally, this work concludes with some discussion and suggests some important avenues for further research. | |||

==Preparation of candidates for experimental conditions== | |||

A major feature of NIMS-OS is that a data file listing candidate experimental conditions is prepared in advance (we refer to this data file a candidates file). In general, because there are many candidates, conducting experiments in all possible conditions is impractical. Thus, automated materials exploration proceeds by selecting promising experimental conditions from these listed candidates. This makes the closed-loop strategy more generalizable. That is, a variety of exploration motivations and robotic systems can be handled by NIMS-OS. | |||

The experimental condition is expressed as a real-valued vector <math>\mathbf{x}_{i} \in \mathbb{R}^{d}</math>. This condition is prepared with information such as the compositions and structures of materials and the processes required to synthesize them. If the number of candidates for the experimental conditions is ''N'', the dataset for candidates is defined as <math>D = \{\mathbf{x}_{i}\}_{i = 1,\ldots,N}</math>. The initial candidates file is created by this dataset ''D''. An example of a candidates file with ''l'' objective functions is presented in Figure 3. All the candidates of ''D'' are written in the first ''d'' columns. In this part, there should be no empty spaces. The next ''l'' columns are used for the objective function values. In this part, at the initial stage, all cells are empty because experiments have not been performed for all the experimental conditions. | |||

Revision as of 23:43, 15 September 2023

| Full article title | NIMS-OS: An automation software to implement a closed loop between artificial intelligence and robotic experiments in materials science |

|---|---|

| Journal | Science and Technology of Advanced Materials: Methods |

| Author(s) | Tamura, Ryo; Tsuda, Koji; Matsuda, Shoichi |

| Author affiliation(s) | The University of Tokyo, National Institute for Materials Science |

| Primary contact | Email: tamura dot ryo at nims dot go dot jp |

| Year published | 2023 |

| Volume and issue | 3(1) |

| Article # | 2232297 |

| DOI | 10.1080/27660400.2023.2232297 |

| ISSN | 2766-0400 |

| Distribution license | Creative Commons Attribution 4.0 International |

| Website | https://www.tandfonline.com/doi/full/10.1080/27660400.2023.2232297 |

| Download | https://www.tandfonline.com/doi/pdf/10.1080/27660400.2023.2232297 (PDF) |

|

|

This article contains rendered mathematical formulae. You may require the TeX All the Things plugin for Chrome or the Native MathML add-on and fonts for Firefox if they don't render properly for you. |

|

|

This article should be considered a work in progress and incomplete. Consider this article incomplete until this notice is removed. |

Abstract

NIMS-OS (NIMS Orchestration System) is a Python library created to realize a closed loop of robotic experiments and artificial intelligence (AI) without human intervention for automated materials exploration. It uses various combinations of modules to operate autonomously. Each module acts as an AI for materials exploration or a controller for a robotic experiments. As AI techniques, Optimization Tools for PHYSics Based on Bayesian Optimization (PHYSBO), BoundLess Objective-free eXploration (BLOX), phase diagram construction (PDC), and random exploration (RE) methods can be used. Moreover, a system called NIMS Automated Robotic Electrochemical Experiments (NAREE) is available as a set of robotic experimental equipment. Visualization tools for the results are also included, which allows users to check the optimization results in real time. Newly created modules for AI and robotic experiments can be added easily to extend the functionality of the system. In addition, we developed a graphical user interface (GUI)-driven application to control NIMS-OS. To demonstrate the operation of NIMS-OS, we consider an automated exploration for new electrolytes. NIMS-OS is available at https://github.com/nimsos-dev/nimsos.

Keywords: NIMS-OS, robotic experiments, artificial intelligence, electrochemistry, materials informatics

Introduction

The integration of robotic experiments and artificial intelligence (AI) is essential to realize automated materials exploration. If an AI system can take on some information tasks conventionally performed by human researchers, robotic systems can then execute the required physical tasks and experiments for materials exploration can proceed automatically. Such a platform may be expected to discover many novel materials and lead to substantial innovation in materials science. In recent years, significant progress has been made in the development of AI techniques and robotic devices suitable for materials exploration.

Since the launch of the Materials Genome Initiative [1], AI techniques have been actively used for materials exploration. [2–4] In general, materials exploration can be regarded as the problem of finding optimal materials from among a materials search space. The elements to be used in the search space must be configured, along with its composition range, process parameter range, and so forth. To solve this problem, black-box optimization methods are useful [5], and various methods have been developed and applied to fit various needs. Bayesian optimization (BO) is among the most frequently used methods in materials science. [6–8]. In this method, promising materials can be selected in the materials search space using the predictions of their properties and the uncertainty of these predictions evaluated by Gaussian process regression. Using BO, various real materials, such as Li-ion conductive materials [9], multilayered metamaterials [10], halide perovskite [11], superalloys [12], and electrolytes [13] have been explored. BO is also used for the automated analysis of materials [14–15]. In addition, many methods have been proposed for black-box optimization in materials exploration, such as genetic algorithms [16–17], Monte Carlo tree search [18], rare event sampling [19], and algorithms using an Ising machine. [20–22] In the future, many more innovative methods are expected to be developed.

Robotic experiments have progressed to realize laboratory automation of chemical analysis and high-throughput screening in the field of biology. [23–26]. Various types of automated analyzers and pipetting devices have been developed, and robotic arms have been used as a transport system to connect these systems. Moreover, robotic technology has been used to explore novel materials, such as thin-film materials [27–28], battery electrolytes [13,29], and photocatalysts. [30] These studies used BO to automate the proposal of promising experimental conditions. This enables a closed loop of robotic experiments and AI that can perform automated materials exploration without human intervention. This approach involves some key advantages, such as the ability to generate materials data of uniform quality and the absence of human error. In contrast, at present, robotics systems are limited in their ability to perform complex material synthesis tasks that require the skills of experts. Thus, further innovation in robotic devices will be important.

In addition to AI and robotic technologies, the control systems and software used to interlink them are also an important element to realize a closed loop without human intervention. Generally, different AI algorithms should be used depending on the motivation of a materials exploration task. Furthermore, the procedure to control the devices should depends on the nature and characteristics of the robotic systems used. Therefore, control software has thus far been developed on a case-by-case basis for different AI algorithms and robotic systems.

In this study, we developed NIMS-OS (NIMS Orchestration System) to realize a closed loop between AI models and robotic experiments, with the aim of establishing a generic control software system. Although this software was written in the Python programming language, we also developed a graphical user interface (GUI)-driven version to improve operability after installation. NIMS-OS treats each AI algorithm and each robotic system as separate modules (see Figure 1). This enables the implementation of a closed loop with any combination of these modules. If modules for new AI algorithms or robotic systems are prepared, new closed-loop systems can be easily controlled via NIMS-OS. One of the advantages of developing such generic control software is the establishment of technical standards for automated materials exploration. For AI algorithms, we determined standard formats for the input and output. Algorithms created according to the standard format can be immediately tested using any currently available robotic system. Specifically, we developed a standard format in which all the experimental conditions to be explored are listed in advance, and the appropriate experimental conditions that have not yet been tested are selected from the list by AI algorithms. The advantage of this approach is that it enables automated materials exploration utilizing materials databases. When utilizing materials databases, the compositional and structural information needs to be converted into materials descriptors, which serve as the materials search space. However, this search space generated from the materials databases cannot be solely defined by a continuous parameter space, and it requires a selection from the pre-listed descriptors. Of course, optimization of continuous parameters can still be handled approximately by preparing a list of grid points that discretize the continuous parameters. Furthermore, we expect this work to contribute to the development of new AI algorithms for automated materials exploration. For robotic systems, we expect modules developed based on NIMS-OS to increase the commonality of operational procedures, leading to cost reductions as new robotic experimental devices are introduced. Note that ChemOS [31] is similar to NIMS-OS; it was developed as an automation system in the field of chemistry. ChemOS specializes in BO within a defined continuous or discretized parameter space and includes several default modules for various BO methods. On the other hand, NIMS-OS offers the capability to perform automated materials explorations not only within a defined parameter space but also utilizing materials databases. In addition to BO, NIMS-OS also incorporates several default implementations of black-box optimization methods to deal with different motivations in materials explorations.

|

Let us briefly introduce the specifications of NIMS-OS. First, a candidates file listing experimental conditions as a materials search space should be prepared in advance. A closed loop is formed according to the following three steps (see Figure 2):

- Step 1: Select promising experimental conditions from the candidates file using an AI model.

- Step 2: Create an input file for the robotic experiments and execute the experiments.

- Step 3: Analyze the output from the experiments and update the candidates file based on the experimental results.

|

Currently, the following AI algorithms are used as modules, which are available for Step 1: (i) Optimization Tools for PHYSics Based on Bayesian Optimization (PHYSBO) [32], (ii) BoundLess Objective-free eXploration (BLOX) [33], and (iii) phase diagram construction (PDC) [34] methods, with the random exploration (RE) approach able to be selected according to the purpose of materials exploration effort. For Steps 2 and 3, a STANdard module (STAN) is provided for robotic experiments, which enables operation checks even without devices, along with a module for NIMS Automated Robotic Electrochemical Experiments (NAREE) [13,35]. We plan to continue developing additional modules for this system.

The reminder of this study is organized as follows. The next section describes the preparation of a candidates file storing experimental conditions, followed by an introduction to the available modules for the AI and robotic experiments in NIMS-OS. Then the use of the Python code, and the usage of the GUI version is explained. As a demonstration, the results of an autonomous electrolyte exploration via a closed-loop approach using PHYSBO and NAREE in NIMS-OS are described. Finally, this work concludes with some discussion and suggests some important avenues for further research.

Preparation of candidates for experimental conditions

A major feature of NIMS-OS is that a data file listing candidate experimental conditions is prepared in advance (we refer to this data file a candidates file). In general, because there are many candidates, conducting experiments in all possible conditions is impractical. Thus, automated materials exploration proceeds by selecting promising experimental conditions from these listed candidates. This makes the closed-loop strategy more generalizable. That is, a variety of exploration motivations and robotic systems can be handled by NIMS-OS.

The experimental condition is expressed as a real-valued vector . This condition is prepared with information such as the compositions and structures of materials and the processes required to synthesize them. If the number of candidates for the experimental conditions is N, the dataset for candidates is defined as . The initial candidates file is created by this dataset D. An example of a candidates file with l objective functions is presented in Figure 3. All the candidates of D are written in the first d columns. In this part, there should be no empty spaces. The next l columns are used for the objective function values. In this part, at the initial stage, all cells are empty because experiments have not been performed for all the experimental conditions.

References

Notes

This presentation is faithful to the original, with only a few minor changes to presentation. In some cases important information was missing from the references, and that information was added. In the original, there are multiple instances of citing research work using the last name of the last author listed, rather than the last name of the first author listed; this may have been a product of Japanese culture tending to read text from right to left. For this version, the last name of the first author was used to be consistent with research norms.