Journal:Autonomous experimental systems in materials science

| Full article title | Autonomous experimental systems in materials science |

|---|---|

| Journal | Science and Technology of Advanced Materials: Methods |

| Author(s) | Ishizuki, Naoya; Shimizu, Ryota; Hitosugi, Taro |

| Author affiliation(s) | Tokyo Institute of Technology, The University of Tokyo |

| Primary contact | Email: hitosugi at g dot ecc dot u dash tokyo dot ac dot jp |

| Year published | 2023 |

| Volume and issue | 3(1) |

| Article # | 2197519 |

| DOI | 10.1080/27660400.2023.2197519 |

| ISSN | 2766-0400 |

| Distribution license | Creative Commons Attribution 4.0 International |

| Website | https://www.tandfonline.com/doi/full/10.1080/27660400.2023.2197519 |

| Download | https://www.tandfonline.com/doi/pdf/10.1080/27660400.2023.2197519 (PDF) |

Abstract

The emergence of autonomous experimental systems (AESs) integrating machine learning (ML) and robots is ushering in a paradigm shift in materials science. Using computer algorithms and robots to decide and perform all experimental steps, these systems require no human intervention. A current direction focuses on discovering unexpected materials and theories with unconventional research approaches. This article reviews the latest achievements and discusses the impact of AESs, which will fundamentally change the way we understand research. Moreover, as AESs continue to develop, the need to think about the role of human researchers becomes more pressing. While ML and robotics can free us from the repetitive aspects of research, we need to understand the strengths and limitations of ML and robots and focus on how humans can perform higher creativity. In addition, we also discuss inventorship and authorship in the era of autonomous systems.

Keywords: autonomous experimental system, closed-loop, machine learning, robots, materials science, inventorship, authorship, human researcher, human’s role

Introduction

The total number of all possible small organic molecules is estimated to be at least 1060[1][2], and from that one can imagine a similarly large number of possible materials being derived using those molecules. This number helps illustrate the vastness of the materials search space, which must contain many materials that can help address current societal problems. In a way, the world of materials is a frontier for exploration, much like space or the deep sea.

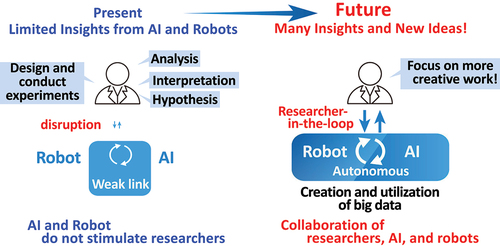

How can we quickly and systematically find unexpected materials within this enormous search space? To this end, materials science needs a tool that can transcend the limits of human capabilities to serve as a materials explorer (Figure 1), akin to a spaceship or a deep-sea exploration vessel.

|

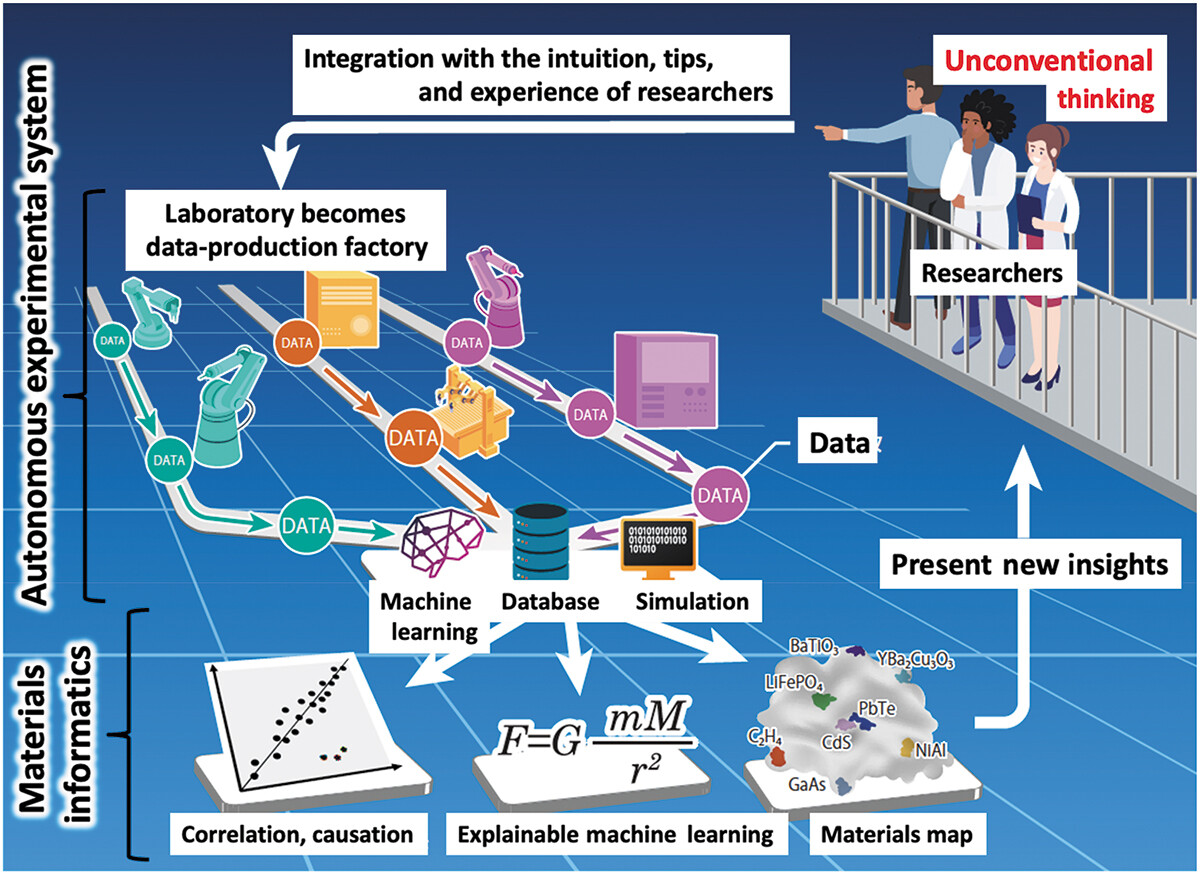

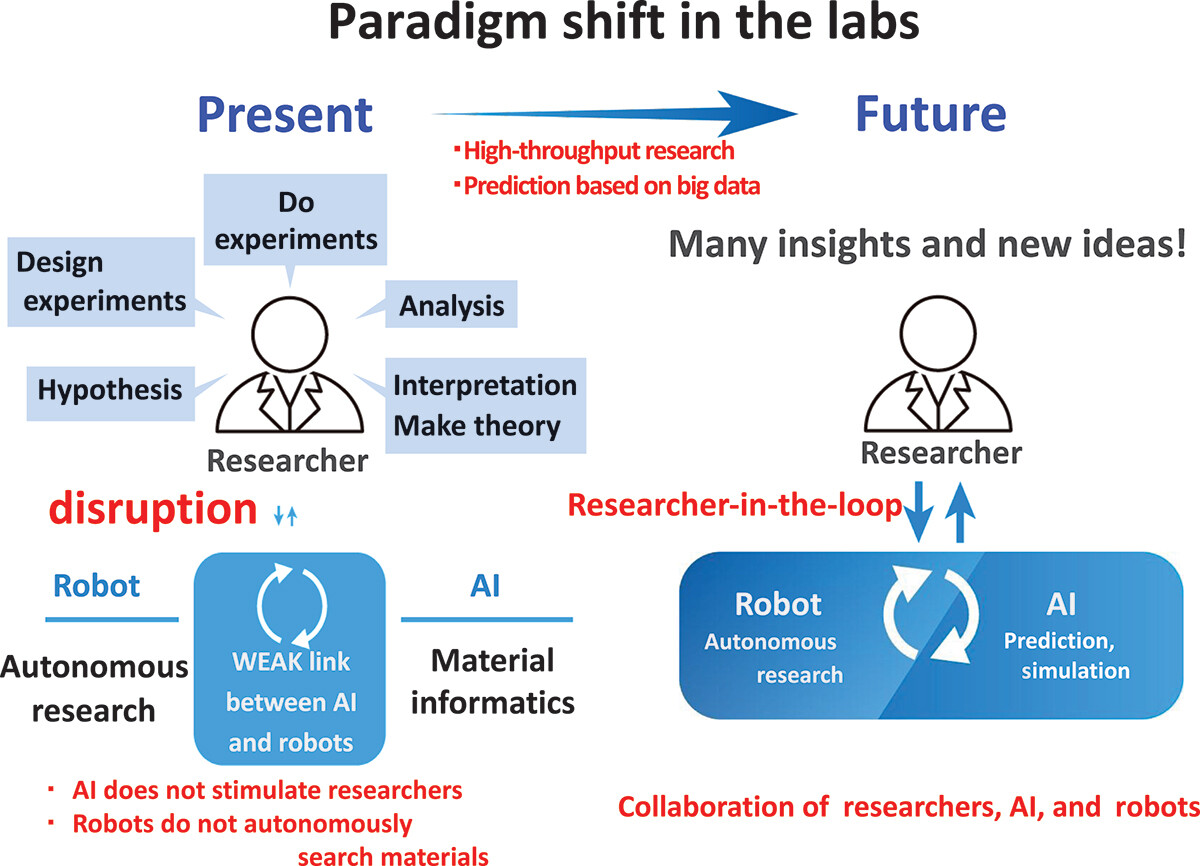

The core of such a materials explorer is the autonomous experimental system (AES) based on machine learning (ML) and robots (green, orange, and purple in Figure 1). Here, the term "autonomous" means that a computer algorithm decides the next experimental steps while robots perform all experimental steps. This approach, which involves no human intervention, is called the closed-loop experiment (Figure 2).

|

In general, new materials are sought in a multi-dimensional space by optimizing many relevant experimental parameters. Because of the vastness of the search space, the manual optimization of these parameters by individual researchers only produces incremental results that do not show the big picture. However, this problem is ideally suited for the AES to address. Figure 2 illustrates one such example. Here, based on the initial instructions, ML decides which compound to synthesize and feeds the corresponding directions to the robots; the robots synthesize, test, and report the results back to the algorithm, repeating the cycle until the desired result is obtained. This autonomous experimental approach drastically speeds up the materials exploration processes.

The concept of the materials explorer fundamentally changes the way we understand and conduct materials research, across three stages:

Stage 1: Optimization of the yield of target substances - Here, the target compound is known, but the optimum synthesis conditions are unknown. The target compound is decided by the human researchers before the experiment, and the AES quickly optimizes the synthesis conditions of the target compound within the search space specified by the human researchers.[3]

Stage 2: Finding new materials with desired properties - Here, the target physical properties are decided, but the compound possessing these properties is unknown. The AES quickly finds the best material within the search space specified by the human researchers. In contrast to Stage 1, it is the composition of the materials that is changed to find new compounds to meet the required physical properties. Materials with a variety of crystal structures and hierarchical structures are also explored.

Stage 3: Finding new materials or principles that no one has thought of before - Here, new materials, theories, and principles that are unexpected to researchers are discovered by combining the results from autonomous experiments, materials informatics, and human researchers (Figure 1).[4]

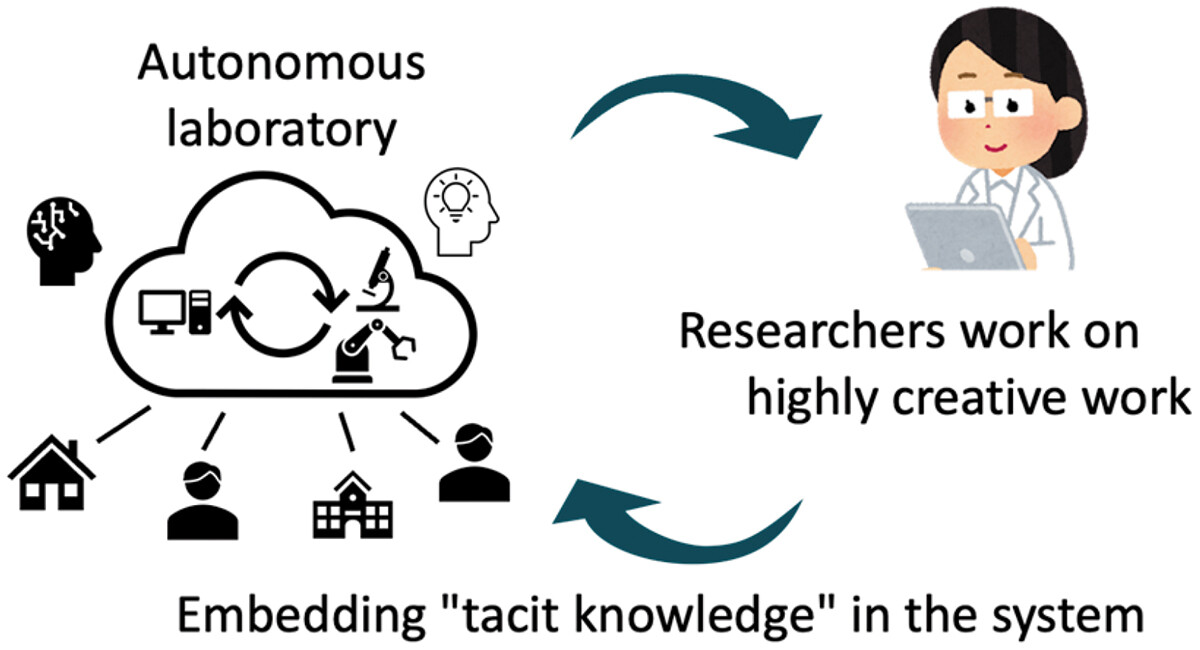

At present, the proofs of concepts of Stages 1 and 2 have been demonstrated in a variety of fields.[5][6][7][8][9][10][11][12][13][14][15][16][17] Expanding the application of AESs to a variety of experiments has become the next objective. Meanwhile, Stage 3 is rapidly advancing owing to the development of ML, robotics, and materials informatics. In this stage, it is critical to embed the researchers’ intuition and experience into the construction of theories. This inclusion of the human role is often referred to as having a "human-in-the-loop" or "researcher-in-the-loop."

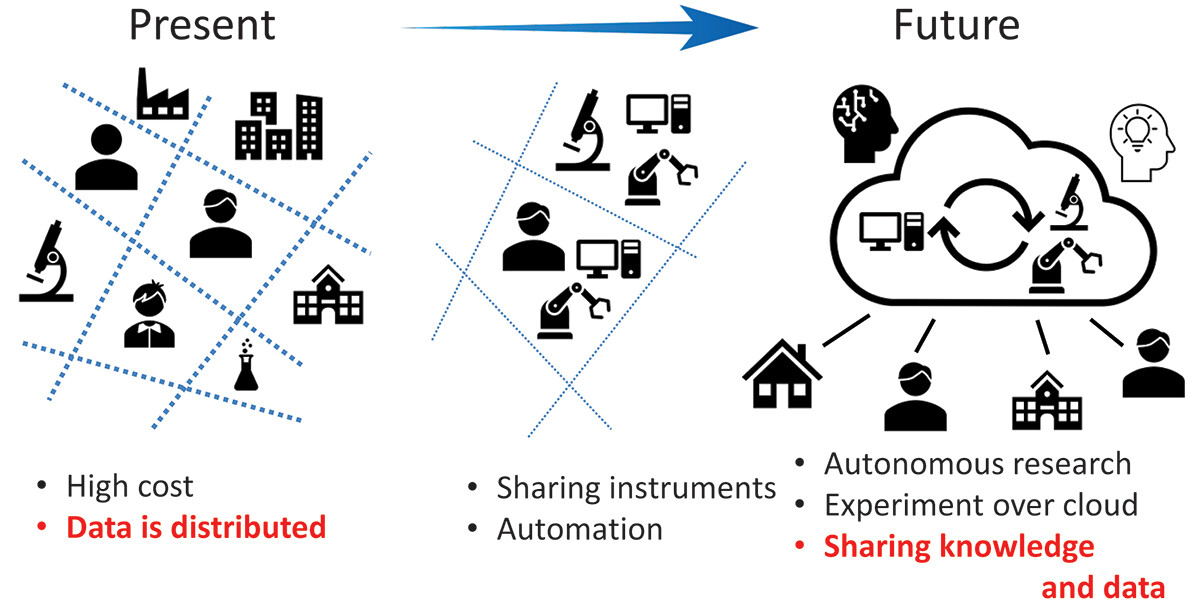

An important point to note is that the transformation resulting from the three stages will change the way researchers think, giving completely new perspectives that researchers cannot obtain using conventional research methods. In addition, the transformation is not limited to a single laboratory; instead, it will change how we conduct research through a digital transformation of materials science. For example, experimentalists can remotely fabricate materials via the internet. In the same way, theorists can fabricate materials to test their predictions.

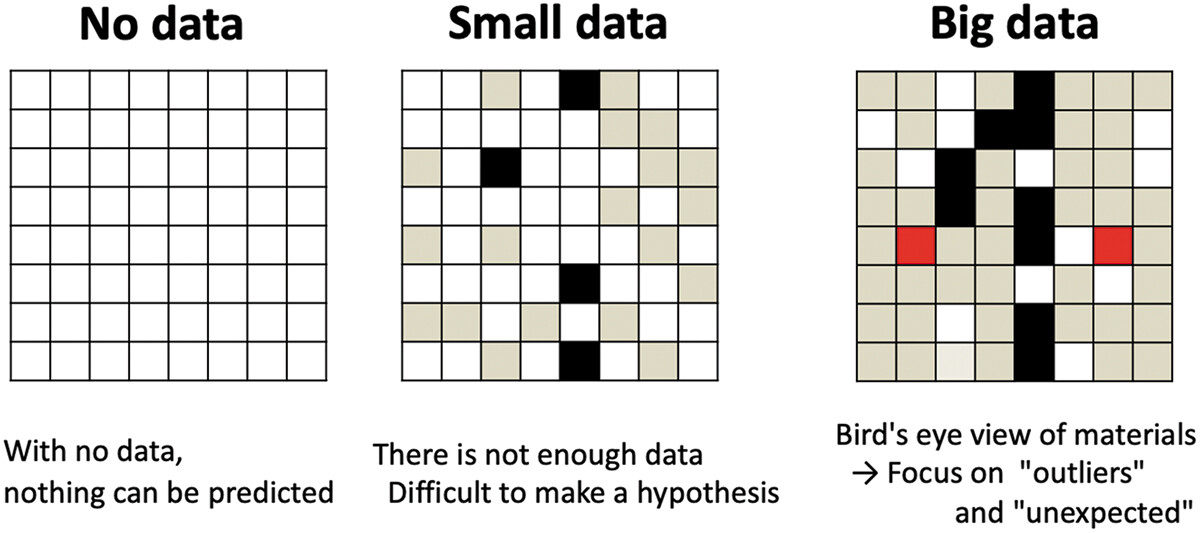

The data generated by such a system would fall into the domain of "big data." Researchers use this big data to extract human-readable information (i.e., via materials informatics). Because ML and robotics alone can neither find insights nor discover concepts in physics and chemistry, human researchers will always remain central to the research. The key point is that materials scientists must understand what ML and robotics can solve, and must set the right problem to be solved. The strength of human researchers lies in concept creation or problem identification in the larger context. Combining these strengths with ML and robotics is critical to accelerating research (i.e., the researcher-in-the-loop).

The process of autonomous materials exploration, however, raises one fundamental question: when experiments are performed autonomously and new materials are found without human intervention, who is the discoverer and inventor? This question not only relates to the authorship of papers and the inventorship of patents, but it also concerns researchers’ motivations. It is important to address this discussion as the autonomous experimental approach develops.

In this article, we review the trends and the prospects of AESs in materials science, specifically through the following aspects:

- the overall status of autonomous experiments in materials science;

- the history and the latest topics of autonomous materials synthesis;

- the future of research using the AES;

- some important take-home lessons we have learned when developing and using such a technology; and

- the future of authorship and inventorship.

Throughout this review, we address what human researchers should focus on in the era of autonomous research. The year 2020 was momentous for this era; there were significant advancements in the field of autonomous research. This review aims to further contribute to the expansion of the era of autonomous materials research.

Present status of autonomous experiments

A brief description of our own autonomous experiments

In the closed-loop cycle shown in Figure 2, researchers only need to choose the material properties to optimize and provide the system with the necessary raw materials; the automatic system then takes control, repeatedly synthesizing and measuring the properties of new compounds until the best one is found. The ML algorithm uses previous knowledge to decide how the synthesis conditions should be changed to approach the desired outcome with each cycle.

Recently, we have developed an autonomous synthesis of inorganic thin films.[3] In this proof-of-concept study, we demonstrated the autonomous fabrication of TiO2 thin films with low resistance and showed that this system accelerates experiments by tenfold.

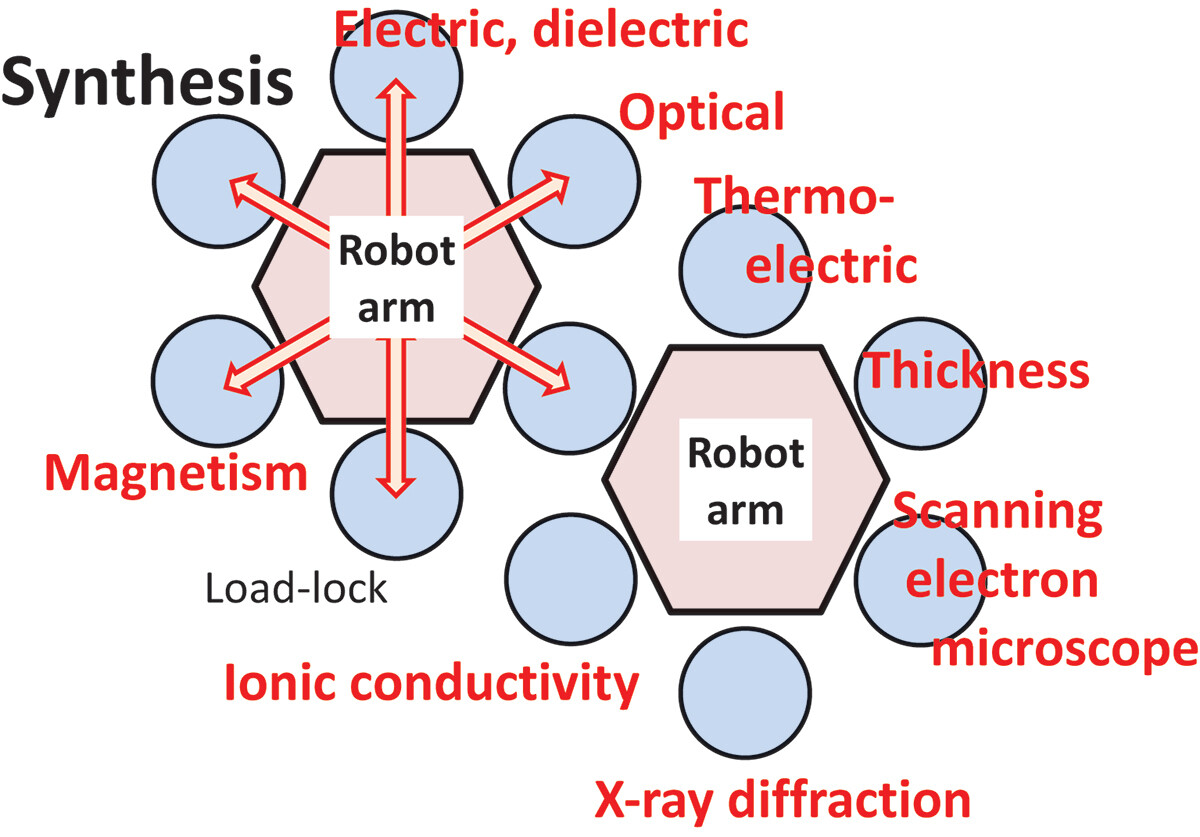

To obtain these results, we have used robotic modules of a sputter deposition apparatus and a robotic device for measuring resistance. Other modules with robotic synthesis and measurement equipment can be connected to this system to adapt to the desired research. The robotic arm transfers the samples from module to module as needed, and the Bayesian optimization algorithm predicts the synthesis parameters for the next iteration.

AES in the world

Recent years have witnessed the rapid progress of autonomous experiments, including a) development of ML technology, b) improvement of robot technology and expansion of its range of applications, and c) realization of autonomous experiments using ML and robots. As discussed in the introduction, examples of autonomous materials syntheses can be found to demonstrate Stages 1 and 2.[5][6][7][8][9][10][11][12][13][14][15][16][17] In this section, we review the history and the latest advances demonstrating these two stages (Table 1).

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stage 1: Optimization of the yield of target substances or reaction conditions

The idea of autonomous materials synthesis using robots has a long history. The first proposal of a fully automated closed-loop robot aiming for the optimization of chemical reaction parameters was published in 1978.[31] However, no experimental results were reported.

In the 1980s, Matsuda et al. reported the optimization of reaction conditions using an autonomous system.[18] The repetition of reagent adjustment, reaction, measurement, and prediction of the next experimental conditions based on the measured results were automatically performed. Here, test tubes were manipulated by a robot. The color-developing reactions for chemical analysis were optimized using the simplex method with three parameters: the amount of two reagents and the reaction time. The exhaustive grid search required 130 experiments, but the robotic system optimized the reaction in less than 28 experiments. While the purpose of this experiment was not to find a new compound but to optimize the color-developing reaction, it is a seminal pioneering work of autonomous experiments.

In 2016, Nikolaev et al. demonstrated an autonomous synthesis of inorganic materials. The authors synthesized carbon nanotubes using chemical vapor deposition.[19] They fabricated multiple columns containing a catalyst layer on a substrate in advance. Then, they heated the individual columns one by one with a laser while repeatedly moving the substrate to synthesize carbon nanotubes with different growth conditions. This heating laser was also used as an excitation source for Raman spectroscopy to observe the growth rate in situ. A genetic algorithm maximized the growth rate; the system optimized the temperature, pressure, and gas composition. Later the group utilized a Bayesian optimization as an optimization algorithm.[32]

For organics, Christensen et al. maximized the yield of the Suzuki-Miyaura coupling reaction using Bayesian optimization.[20] They used a commercially available liquid handling robot and ChemOS[33][34][35] for autonomous experiments. In the Bayesian optimization, Phoenics[36] and Gryffin[37] algorithms were used to optimize categorical variables (catalyst type) in addition to continuous variables (amount of catalyst, amount of feedstock, reaction temperature). Parallel autonomous process optimization experiments in batches were performed to shorten the time to complete the optimization.

The autonomous synthesis of organics using flow reactors was reported by McMullen et al.[21] The authors first reported on a Heck reaction, where the yield was maximized by optimizing the raw materials ratio and reaction time as independent variables, using the simplex method (Nelder-Mead method). Subsequently, the authors worked on other autonomous syntheses using flow reactors[38][39]. For example, they applied SNOBFIT (Stable Noisy Optimization by Branch and Fit) to a variety of reactions using a modular system.[40] In 2015, Sans et al. optimized the yield of an imine synthesis.[22] The authors also used the simplex method to tune the raw materials ratio and reaction time. The system was equipped with in-line nuclear magnetic resonance spectroscopy. The group also developed an organic synthesis robot that navigates chemical reaction spaces.[41][42][43]

Stage 2: Finding new materials with desired properties

In 2009, King et al. reported a seminal work[23][24], where a robot "Adam" autonomously generated functional genomics hypotheses and experimentally tested the hypotheses using robots. The system measured the growth curves of selected microbial strains growing in defined media, "discovering" three novel yeast genes. The equipment comprised a liquid handling robot, a robot arm, and an incubator, all fixed in one place.

In 2020, Burger et al. demonstrated a free-roaming robot that moved around the laboratory to perform autonomous experiments using the same equipment as those used by its human counterparts.[25] The robot aimed to maximize photocatalytic activity by optimizing the concentrations of photocatalyst and additives. Based on Bayesian optimization, the robot identified the photocatalyst mixtures that were six times more active than the initial formulation. The robot completed 688 experiments in eight days. This number of experiments would take a human researcher several months. For reagent weighing, the robot handled both powder and liquid materials.

In the same year, MacLeod et al. reported the autonomous fabrication of organic thin films.[26] A robot "Ada," equipped with a gripper, a pipette mount, and a robotic arm for liquid injection and substrate transfer, maximized the hole mobility of organic hole transport materials used in perovskite solar cells. The dopant concentrations and annealing time were optimized using Bayesian optimization. Ada finished the experiment in five days instead of nine months. Later, the group used Ada to define a Pareto front of conductivities and processing temperatures for palladium films formed by combustion synthesis.[44] There are other liquid handling robots developed for closed-loop, e.g., Wu et al. reported an automated platform for organic laser discovery, including not only synthesis and compound identification but also integrated target property characterization.[45]

There are several autonomous experiments based on flow reactors (synthesis in the liquid phase). For inorganic nanoparticles, Krishnadasan et al. autonomously synthesized CdSe nanoparticles with optimized intensity for a chosen emission wavelength in 2007 (SNOBFIT method).[27] Later, other groups reported various autonomous experiments on inorganic nanoparticles.[46][47][48][49][50] For example, Tao et al. synthesized Au nanoparticles[28] with targeted spectroscopic characteristics using the above-mentioned Gryffin[37] in 2021.

For organic compounds, Desai et al. synthesized Abl kinase inhibitors with maximum activity in 2013.[29] Out of 270 possible combinations (10 types × 27 types) from the raw materials, the system found the novel Abl kinase inhibitor after synthesizing only 21 compounds. The prediction model used random forest regression to handle the types of raw materials with different structures.

Dave et al. reported isolating aqueous electrolytes with the maximum electrochemical window in 2020.[30] The authors used Bayesian optimization to optimize the solution volume of three aqueous Li salts or four aqueous Na salts. The results indicated that non-smooth chemical responses are observed along the axis of the amount of NaBr. The authors pointed out that log-scaling, which varies rapidly with quantity, such as the amount of NaBr, gives the response surface both smaller gradients along this axis and a much-improved performance because Gaussian process regression requires an assumption of smoothness on the response surface. They also pointed out that the selection and presentation of the design space for materials search are of utmost importance to autonomous task design.

Future of Stages 1 and 2: Autonomously search within the preset search space

Currently, Stages 1 and 2 are not widespread because the range of applicable experiments is still limited. As more sophisticated robots are developed, the application of autonomous research will expand in turn. The problem lies in that conventional robots are rigidly designed for precision, aiming for zero error. Because they are programmed based on if-then statements, these robots cannot respond flexibly to changing situations. Therefore, it is difficult to implement the tacit knowledge of skilled human researchers in robot systems. With soft control, soft structure, multiple sensing devices, and ML, a more flexible robot can absorb errors and disruptions, and can operate without stoppage or breakdowns.[51][52] Thus, developing robot technology that can respond flexibly until the goal is achieved is important. To this end, it is essential to develop new techniques for robots to learn the minute details of any required motions.

When versatile robots capable of performing a variety of experiments become affordable, the introduction of robots will rapidly expand into many research fields. At the time of this writing, the cost of robots is reducing rapidly to the point where labs can consider using such robot-experiment automation. However, more effort is needed to help materials scientists implement robots into their experiments.

We note that not all researchers will adopt this style of research. The conventional research approach—which relies on researchers’ experience, knowledge, and intuition—will remain essential for conceiving new synthetic methods and analytical techniques. We expect there will be a hybrid between conventional and autonomous approaches.

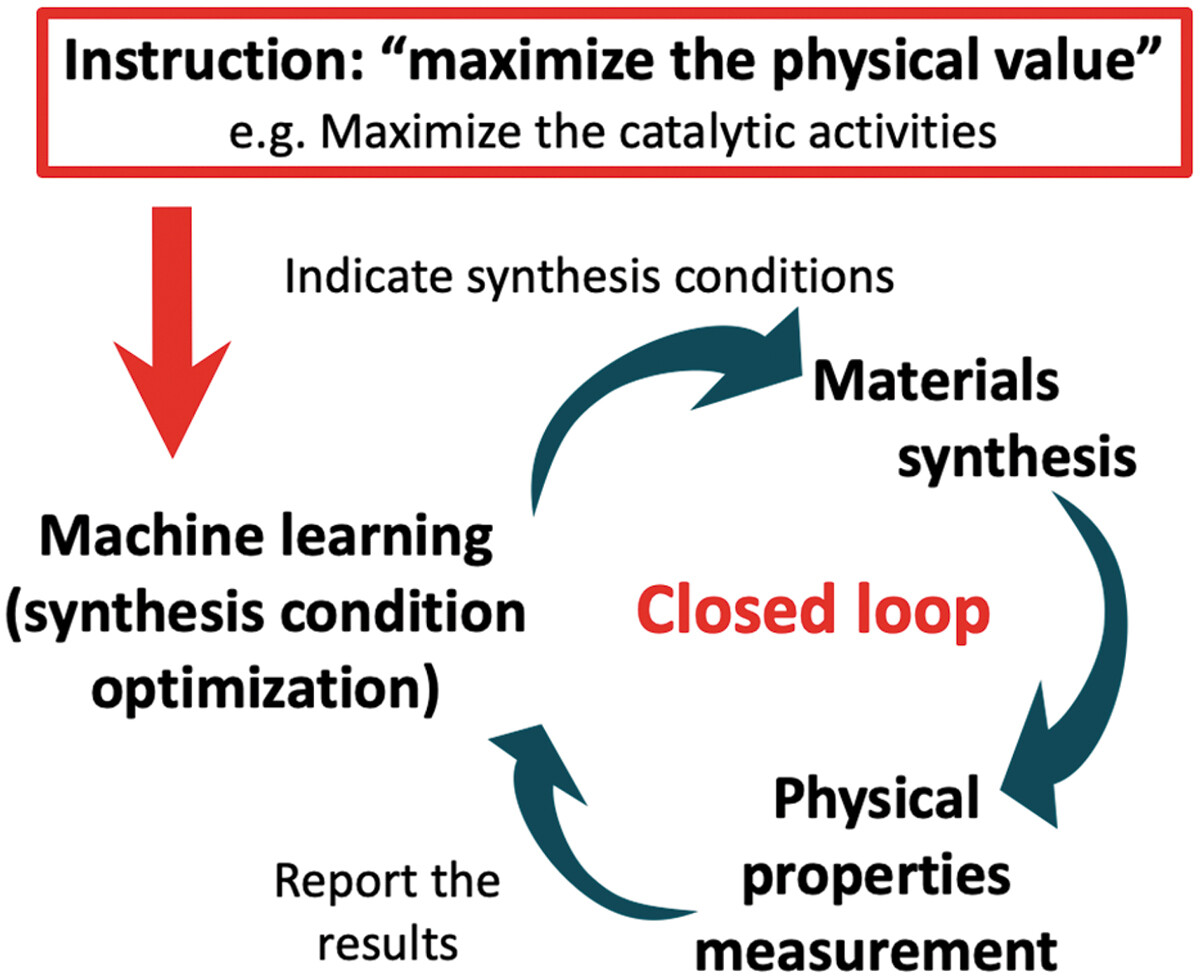

AESs are not only useful for performing high-throughput experiments; the most critical aim is to help human researchers deepen their research. Human researchers need to think about how to analyze the collected data, how the new materials can be used, and what theories can be deduced from unexpected results. AESs free human researchers from repetitive tasks and enable researchers to conduct innovative research. Furthermore, combining the system with advanced materials prediction based on computer simulation is the step that enables human researchers to perform more creative work (Figure 3).

|

With the implementation of AESs, theorists can test their original ideas. Once theorists predict a promising material, they can log on to the AES via the internet and synthesize the new material. Currently, we are developing a system capable of automatically synthesizing materials from simple instructions, such as "synthesize AxByCz with a crystal structure of D." The system automatically measures X-ray diffraction patterns and feeds the results back to the algorithm to predict the next synthesis condition.

Stage 3: Finding materials that no one has thought of before

Because the AES will generate increasingly larger amounts of data, it is essential to combine this type of system with materials informatics and computer simulations to extend human thinking. In so doing, the generated data will promote the emergence of unexpected results that are beyond conventional theories and experiences. It is also important to embed the researchers’ intuition and experience, which are tacit knowledge, into the autonomous system and share them with other researchers (Figure 4).

|

The following are some of the remaining challenges.

Increasing the amount of reliable materials data (materials checkup system and measurement)

To date, materials informatics is still limited by the lack of a reliable materials experiment database. Such a database cannot be manually acquired. To this end, AESs enable the storage of all data, ranging from the fabrication processes (synthesis conditions and experimental environment) to the structural and composition information, to the measured materials properties. Even the negative data (data that do not show the desired values) are stored for later use. This inclusive approach to data storage drastically increases the amount of data available for accurate prediction based on ML. In addition, all data are highly reproducible because they are not acquired by humans (i.e., devoid of human errors). Therefore, it is possible to analyze in detail which process parameters are correlated with physical properties, leading to technology for predicting synthetic processes (i.e., process informatics).

The sheer increase in experimental speed directly translates to an increase in the amount of materials data. The speed of autonomous experiments is estimated to be at least one order of magnitude faster than conventional experiments; it is possible to accelerate the acquisition of measurement data by another order of magnitude using the materials checkup system (Figure 5).[3]

|

In conventional research, human researchers often need to transport their samples to multiple analysis systems to evaluate the physical properties. To avoid errors associated with sample transport and shorten the time for analysis, all analytical modules should be connected to each other. Connecting multiple materials property measurement devices and automatically measuring one after another enable multifaceted materials characterization (Figure 5). With the recent development of measurement and analysis informatics[53], it is possible to perform measurements with even higher accuracy, precision, and sensitivity measurements in a short period of time.[54]

The key to the multifaceted evaluation is to increase the probability of finding unexpected results. We have already experienced finding an unexpected electrode material using multifaceted evaluation while targeting the synthesis of a solid electrolyte.

Constructing scientific theories from a bird’s-eye view

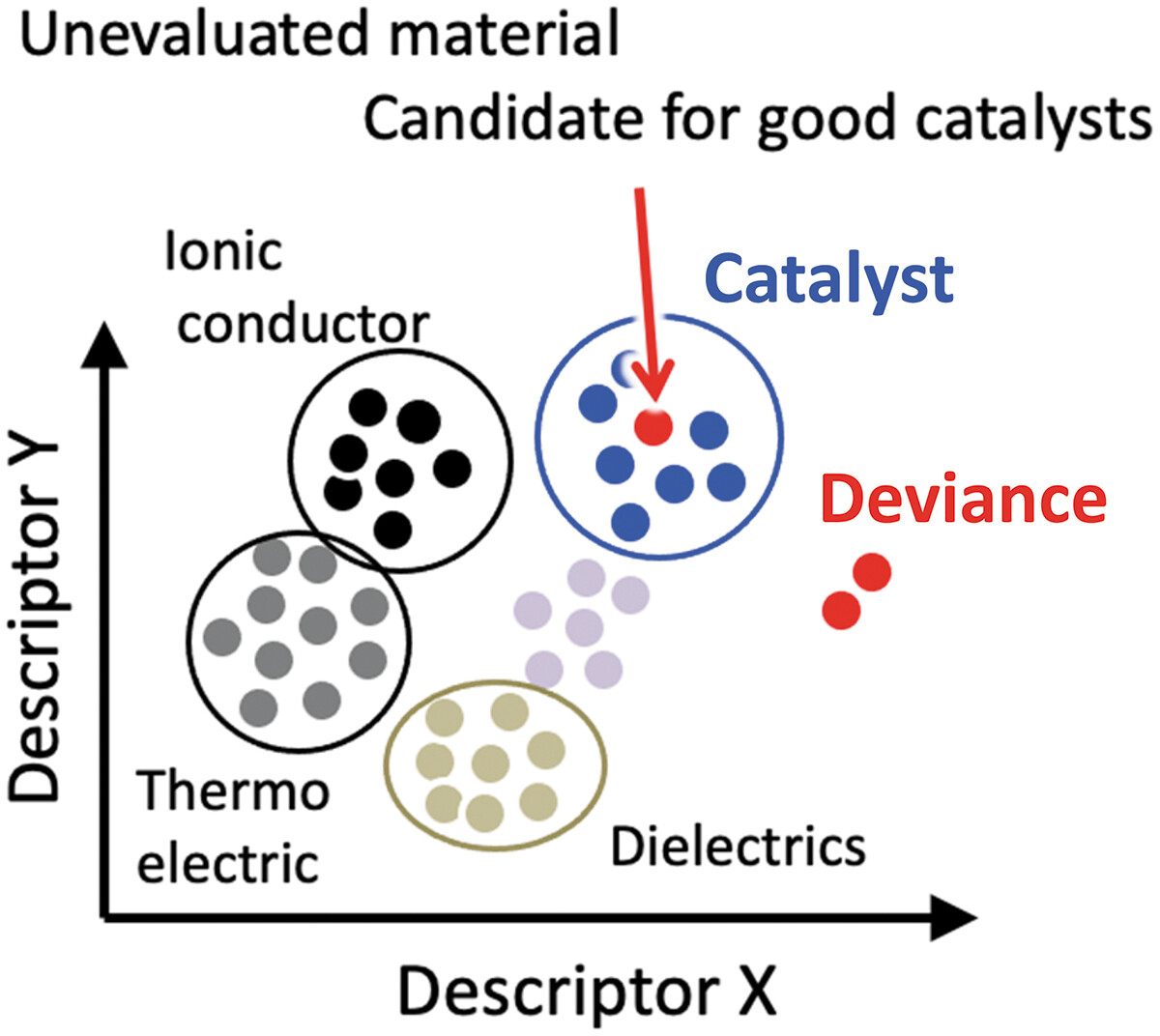

The AES does not search aimlessly in the search space. Instead, it creates a materials map[55] based on the large amount of data described in the previous section to give a bird’s-eye view of the materials world (Figure 6).

|

Specifically, materials informatics methods help organize the enormous amount of multi-dimensional data (e.g., actual experimental data and high-throughput first-principles simulations) into human-readable forms. This data is overlaid with previously reported experimental and simulated data to create a materials map.

The materials map depicts the untapped and promising areas that should be experimentally verified. This depiction stimulates the researchers’ thinking in ways conventional research methods cannot. The new ideas can then be immediately tested using the AES (Figure 1).

The unveiling of the hidden correlations and relationships between materials properties and processes will promote the construction of new theories. Until now, completely unexpected and never-before-observed results are often ignored because it has been difficult to distinguish whether they are real or whether they are caused by experimental error. However, these results can be reproduced when using the AES; unexpected results (i.e., "outliers") will not be ignored, making it possible to create new scientific theories that explain them (Figure 7).

|

Lastly, to overview a massive amount of materials data, it is necessary to have the technology capable of converting this data for humans to understand. In particular, the development of technologies for explainable ML and visualization of information in a multi-dimensional space through dimensionality reduction is mandatory.

Important points for the actual operation of an autonomous system

This section discusses some important take-home lessons we have learned from our constructing and operating the AES.

Setting the right research topic

It is not practical to leave all experimental operations to ML and robots; instead, it is crucial to choose the right tasks. The current autonomous experimental technology works best when applied to processes with well-developed instructions. Techniques with broad and general applications that many researchers use are better suited for applying to autonomous systems. For example, we chose to automate sputtering thin-film deposition because it is widely used in the field, including the semiconductor industry.

Another point concerns the human operator’s psychological aspect. In our experiments, the human operators perform two tasks: setting up the raw materials and cleaning up the pieces used in the experiments. Because the operator performs these tasks according to the robot’s schedule, in some cases, the operator may feel as if being controlled by robots. It is critical that robots perform these tasks in the future.

Cost issues

It is difficult to introduce an autonomous system to every laboratory because of its cost. There are three points to consider. The first point is that robots are becoming less expensive, and their range of applications is expanding. The price depends on positioning accuracy and repeatability. Because robots are generally capable of working 24 hours a day, 7 days a week, the operational cost depends on the tasks and the labor cost. The software cost has also decreased, as robots can be run using LabVIEW or Python, two widely used programming environments. In this way, the total system cost is becoming affordable, and we are now in an era when robots can be introduced to laboratories. We note that it is important to provide open labs for researchers unaware of the possibilities of autonomous systems, to get acquainted with the actual setups and operations of such systems.

The second point is to promote sharing the autonomous system via the internet, providing access to the system from anywhere in the world (via cloud computing for the laboratory, sharing experiments over the cloud; Figure 8). Currently, the equipment in the laboratory is only used during the daytime on weekdays and therefore is not fully utilized. Full utilization around the clock through sharing will enhance cost-effectiveness; it will also enable materials fabrication while researchers are at home, making a remote style of laboratory work possible.

|

The last point is the perspective of multifaceted characterization. As shown in Figure 5, multiple analytic instruments automatically characterize a range of properties. The time previously spent by researchers on measurements can now be allocated to higher value-added tasks, further enhancing cost-effectiveness.

Change in the experimental sequences

Conventionally, the materials to be synthesized are decided before the synthesis. After the synthesis, compositions and structures are analyzed to confirm that the aimed materials have been synthesized. After identifying the compounds, the properties are evaluated.

Autonomous experiments reverse this sequence. Because the goal of the research is to determine the material with superior physical properties, there is no need to decide what materials to synthesize in advance. The compositional and structural analyses to identify the materials are only performed once the robot has synthesized materials with the optimum properties.

Autonomous experiments applied to device fabrications show a similar sequence reversal. The system automatically fabricates a device, evaluates its performance, and tunes the next materials based on the results. Again, there is no need to know the details of the materials prior to device fabrications.

From a broader perspective, autonomous systems change our attitude toward research. New ideas—which previously required careful experimental planning to be tested with a small number of trials—can now be tested immediately using an autonomous system. With automation, we can comfortably conduct experiments even with a naive idea because the autonomous system performs experiments, and the number of experiments can be increased at will.

Steps for implementation and the rise of the lab-system integrator

How should a materials research lab start out with automation and autonomous experiments? The following points should be considered when integrating materials synthesis and evaluation, robotics, ML, and overall system control.

- Clarify the workflow and choose the appropriate tasks for automation (see the prior discussion about setting the right research topic).

- Set up a team, including an engineer who understands informatics. In addition, include an engineer familiar with equipment control and systemization.

- The introduction of robots can be expensive. It may be difficult to introduce the whole system at once. Therefore, it is necessary to create a chain of successes to maintain continuous funding. The critical point is to draw an overall plan and accumulate small successes.

Standardizing the lab equipment is essential to reduce the time to set up and the cost. Shortly, lab-system integrators will emerge. There is a movement in the world towards aligning the format of all mechanical interfaces and communication protocol; each piece of equipment will be integrated to form an automation system.[15] Standardization and de facto standards are key for lab-system integrators, and the technology must be launched quickly.

The autonomous system and intellectual property

Currently, the intellectual property of newly discovered or invented materials is effectuated through scientific publication or patent application. However, when the discovery/invention is accomplished without human intervention, can we say that a human discovered or invented the materials? Can the AES be an inventor under patent law?[25] Can the system be an author of a paper? Furthermore, patents are designed to protect inventions that are not only new, but also involve an inventive step; will the autonomous system change how inventive steps are determined? In other words, will the autonomous system change the standard of what constitutes an easy invention? In this section, we discuss inventorship, inventive step, and authorship.

Inventorship – Who is an inventor?

Whether AI systems, including autonomous systems, should be treated as an inventor under patent law is a hot topic.[56][57][58] A person who makes an invention is called the inventor (we note that the patent owner is often not the inventor but the company that employs the inventor). However, if AI makes the invention, can it be considered the inventor under patent law?

Abbott et al. applied for patents naming the AI "DABUS" as the inventor in several countries and regions to raise this issue.[59] They proposed that the inventor is DABUS and the patent owner would be the person who owns DABUS. For this case, the South African patent authorities have accepted the patent applications with DABUS as the sole inventor[60]; however, we note that the decision can still be overturned by the respective superior courts.

Since the wording of patent acts and their interpretations differ from one jurisdiction to another, whether AI can be treated by patent acts as an inventor also differs. In contrast to the above examples, the patent offices and courts in the U.S., U.K., Australia, the European Patent Office, and the Japan Patent Office have all ruled that only human beings can be the inventor under the patent acts, rejecting the notion of DABUS being treated as an inventor.[58][59][61][62][63] In such countries/regions, even when a new material is discovered by an AES, only human researchers who have operated the system and contributed creatively may be treated as inventors. As mentioned prior, the current level of technology still needs significant human contribution to conduct the research.

However, there is an argument that if the AES becomes more autonomous and the level of human contribution continues to decrease, the human researcher may no longer be treated as the inventor. For example, in Japan, the inventor is recognized as a person who conceives an invention or creates the specific materials based on the conceived idea.[64][65] From this perspective, if the AES both conceives and creates a specific material, the human would no longer be considered the inventor. As the autonomous system evolves, in order to be recognized as the inventor, future human researchers will have to either exercise creativity independently from the AES or demonstrate that the AES is used as a tool.

Inventive step – Is an invention easily invented?

To be protected by a patent, an invention must satisfy the definition of inventive step (non-obviousness in the US or Canada). The question here is in what way the AES will change how the inventive step is determined. In the following, we discuss the impact of the system on the inventive step in the future, according to the Japanese patent system.

By definition, an inventive step requires that an ordinary skilled person in the field not be able to make the invention easily at the time of filing the patent application. In Japan[66], patent examiners determine the inventive step by assessing (1) factors indicating the absence of inventive step, and (2) factors supporting the existence of inventive step. Specifically, factor (1) questions whether a skilled person in the field could have easily made the invention, and factor (2) questions, for example, the existence of advantageous effects exceeding predictability based on the state of the art.

At present, because AI in materials exploration is still in its infancy and its accuracy remains low, the current patent examination practices determining inventive step have not been changed. However, many researchers in intellectual properties and business associations point out that, as AI’s accuracy continues to rise and becomes widely used, the difficulty of achieving new invention will be lowered for the skilled person in the field, raising the standard for what satisfies the definition of inventive step.[67][68][69][70][71] In this case, how the inventive step is legally determined may be changed in the future.

Here we apply this argument to the finding of novel materials by the AES. At this time, the system is not yet widely used, but, in the future, the situation may change as this system becomes well implemented or shared in laboratories. Then, we believe the determination of the inventive step may be changed by a shift in the balance between factors (1) and (2). For example, because the AES excels at optimizing numerical conditions, it is conceivable that many invention cases involving such optimizations would be accessible to an ordinary skilled person in the field with access to the AES. Such cases would make factor (1) stronger because it is sufficiently reasoned for the ordinary skilled person to arrive at the invention, causing the standard for satisfying the inventive step to be raised. Although the possibility to surpass the raised standard by considering a combination of factor (2), such as advantageous effects, the chance of satisfying the inventive step decreases if the current research and development approach remains unchanged.

To obtain patent protection in a future where the AES is widely used, human researchers will have to achieve the inventive step by redirecting their creativity away from the strengths of the AES, in addition to the inventorship mentioned above. For example, the AES will never be able to conceive highly innovative synthesis techniques, or develop new characterization techniques. Furthermore, even for inventions involving optimization of numerical conditions, human creativity will contribute to the inventive step when it is difficult even for the AES to come up with a specific parameter. In addition, new materials discovered by an AES will still need to be put to use, requiring human input to create new devices by combining many materials, utilizing hierarchical structures. Lastly, it is human beings who will think about what issues facing society and how to solve them; thus, the role of the human researchers is to judge the value and to decide what to do next. This big-picture perspective will lead to new inventions that only humans can think of.

Authorship – Who is an author of academic papers?

Each journal and publisher has its authorship guidelines. One well-known example is the authorship guidelines published by the Committee on Publication Ethics (COPE)[72], which states that "the minimum requirements for authorship, common to all definitions, are (A) substantial contribution to the work and (B) accountability for the work that was done and its presentation in a publication." Another well-known example from the International Committee of Medical Journal Editors (ICMJE)[73] also includes the same concept as requirements (A) and (B).

Although most scientists disapprove of articles crediting the AI tool as an author, an AI tool such as ChatGPT has listed its name as an author.[74][75][76] However, these cases do not focus on the AES but mainly show that AI can generate sentences. Whether or not the AES can be treated as an author of an academic discovery is a quite important issue and should be discussed.

So, let’s consider the case where human researchers write a manuscript on a new material discovered by the AES. At the current technological level, while the AES can satisfy substantial contribution (requirement A) because the system has performed the laboratory procedures leading to the new-material discovery, it cannot provide accountability (requirement B). There are many theories on whether AI can have accountability[77]; however, at present, the general view is that only human researchers can be held accountable.[78] Until AI can provide accountability, AI is not eligible for academic authorship.

Summary

As the involvement of ML and robotics continues to expand in scientific research, the roles of human researchers have become a central question. ML and robots will not replace researchers; from the onset, AESs have aimed at providing researchers with the chance to think and to be more creative. The important point is that scientists understand both the limitations and the possibilities of ML and robotics, and apply these techniques to the right problem. Even in an age where ML and robots perform most of the laboratory procedures, human researchers will always be the main players. This approach to automation and autonomy will exponentially accelerate creative research and development, contributing to the future development of science, technology, and industry.

Acknowledgements

We would like to thank R. Nakayama, S. Kobayashi, and T. Kimura at Tokyo Institute of Technology and D. Packwood at Kyoto University for their continuous discussions. We thank P. Han for editing the manuscript.

Funding

This research was supported by JST-CREST [Grant No. JPMJCR1523], JST-MIRAI [Grant No. JPMJMI21G2], and MEXT Program: Data Creation and Utilization-Type Material Research and Development Project [Grant No. JPMXP1122712807].

Conflict of interest

No potential conflict of interest was reported by the author(s).

References

- ↑ Bohacek, R. S.; McMartin, C.; Guida, W. C. (1 January 1996). "The art and practice of structure-based drug design: a molecular modeling perspective". Medicinal Research Reviews 16 (1): 3–50. doi:10.1002/(SICI)1098-1128(199601)16:1<3::AID-MED1>3.0.CO;2-6. ISSN 0198-6325. PMID 8788213. https://pubmed.ncbi.nlm.nih.gov/8788213.

- ↑ Kirkpatrick, Peter; Ellis, Clare (1 December 2004). "Chemical space" (in en). Nature 432 (7019): 823–823. doi:10.1038/432823a. ISSN 0028-0836. https://www.nature.com/articles/432823a.

- ↑ 3.0 3.1 3.2 3.3 3.4 Shimizu, Ryota; Kobayashi, Shigeru; Watanabe, Yuki; Ando, Yasunobu; Hitosugi, Taro (1 November 2020). "Autonomous materials synthesis by machine learning and robotics" (in en). APL Materials 8 (11): 111110. doi:10.1063/5.0020370. ISSN 2166-532X. https://pubs.aip.org/apm/article/8/11/111110/569817/Autonomous-materials-synthesis-by-machine-learning.

- ↑ Kitano, Hiroaki (18 June 2021). "Nobel Turing Challenge: creating the engine for scientific discovery" (in en). npj Systems Biology and Applications 7 (1): 29. doi:10.1038/s41540-021-00189-3. ISSN 2056-7189. PMC PMC8213706. PMID 34145287. https://www.nature.com/articles/s41540-021-00189-3.

- ↑ 5.0 5.1 Tabor, Daniel P.; Roch, Loïc M.; Saikin, Semion K.; Kreisbeck, Christoph; Sheberla, Dennis; Montoya, Joseph H.; Dwaraknath, Shyam; Aykol, Muratahan et al. (26 April 2018). "Accelerating the discovery of materials for clean energy in the era of smart automation" (in en). Nature Reviews Materials 3 (5): 5–20. doi:10.1038/s41578-018-0005-z. ISSN 2058-8437. https://www.nature.com/articles/s41578-018-0005-z.

- ↑ 6.0 6.1 Dimitrov, Tanja; Kreisbeck, Christoph; Becker, Jill S.; Aspuru-Guzik, Alán; Saikin, Semion K. (17 July 2019). "Autonomous Molecular Design: Then and Now" (in en). ACS Applied Materials & Interfaces 11 (28): 24825–24836. doi:10.1021/acsami.9b01226. ISSN 1944-8244. https://pubs.acs.org/doi/10.1021/acsami.9b01226.

- ↑ 7.0 7.1 Flores-Leonar, Martha M.; Mejía-Mendoza, Luis M.; Aguilar-Granda, Andrés; Sanchez-Lengeling, Benjamin; Tribukait, Hermann; Amador-Bedolla, Carlos; Aspuru-Guzik, Alán (1 October 2020). "Materials Acceleration Platforms: On the way to autonomous experimentation" (in en). Current Opinion in Green and Sustainable Chemistry 25: 100370. doi:10.1016/j.cogsc.2020.100370. https://linkinghub.elsevier.com/retrieve/pii/S2452223620300596.

- ↑ 8.0 8.1 Coley, Connor W.; Eyke, Natalie S.; Jensen, Klavs F. (14 December 2020). "Autonomous Discovery in the Chemical Sciences Part I: Progress" (in en). Angewandte Chemie International Edition 59 (51): 22858–22893. doi:10.1002/anie.201909987. ISSN 1433-7851. https://onlinelibrary.wiley.com/doi/10.1002/anie.201909987.

- ↑ 9.0 9.1 Coley, Connor W.; Eyke, Natalie S.; Jensen, Klavs F. (21 December 2020). "Autonomous Discovery in the Chemical Sciences Part II: Outlook" (in en). Angewandte Chemie International Edition 59 (52): 23414–23436. doi:10.1002/anie.201909989. ISSN 1433-7851. https://onlinelibrary.wiley.com/doi/10.1002/anie.201909989.

- ↑ 10.0 10.1 Gromski, Piotr S.; Granda, Jarosław M.; Cronin, Leroy (1 January 2020). "Universal Chemical Synthesis and Discovery with ‘The Chemputer’" (in en). Trends in Chemistry 2 (1): 4–12. doi:10.1016/j.trechm.2019.07.004. https://linkinghub.elsevier.com/retrieve/pii/S2589597419301868.

- ↑ 11.0 11.1 Wilbraham, Liam; Mehr, S. Hessam M.; Cronin, Leroy (19 January 2021). "Digitizing Chemistry Using the Chemical Processing Unit: From Synthesis to Discovery" (in en). Accounts of Chemical Research 54 (2): 253–262. doi:10.1021/acs.accounts.0c00674. ISSN 0001-4842. https://pubs.acs.org/doi/10.1021/acs.accounts.0c00674.

- ↑ 12.0 12.1 Szymanski, Nathan J.; Zeng, Yan; Huo, Haoyan; Bartel, Christopher J.; Kim, Haegyeom; Ceder, Gerbrand (2021). "Toward autonomous design and synthesis of novel inorganic materials" (in en). Materials Horizons 8 (8): 2169–2198. doi:10.1039/D1MH00495F. ISSN 2051-6347. http://xlink.rsc.org/?DOI=D1MH00495F.

- ↑ 13.0 13.1 Stach, Eric; DeCost, Brian; Kusne, A. Gilad; Hattrick-Simpers, Jason; Brown, Keith A.; Reyes, Kristofer G.; Schrier, Joshua; Billinge, Simon et al. (1 September 2021). "Autonomous experimentation systems for materials development: A community perspective" (in en). Matter 4 (9): 2702–2726. doi:10.1016/j.matt.2021.06.036. https://linkinghub.elsevier.com/retrieve/pii/S2590238521003064.

- ↑ 14.0 14.1 Fabry, David C.; Sugiono, Erli; Rueping, Magnus (1 April 2014). "Self-Optimizing Reactor Systems: Algorithms, On-line Analytics, Setups, and Strategies for Accelerating Continuous Flow Process Optimization" (in en). Israel Journal of Chemistry 54 (4): 341–350. doi:10.1002/ijch.201300080. https://onlinelibrary.wiley.com/doi/10.1002/ijch.201300080.

- ↑ 15.0 15.1 15.2 Wagner, Jerrit; Berger, Christian G.; Du, Xiaoyan; Stubhan, Tobias; Hauch, Jens A.; Brabec, Christoph J. (1 October 2021). "The evolution of Materials Acceleration Platforms: toward the laboratory of the future with AMANDA" (in en). Journal of Materials Science 56 (29): 16422–16446. doi:10.1007/s10853-021-06281-7. ISSN 0022-2461. https://link.springer.com/10.1007/s10853-021-06281-7.

- ↑ 16.0 16.1 Seifrid, Martin; Pollice, Robert; Aguilar-Granda, Andrés; Morgan Chan, Zamyla; Hotta, Kazuhiro; Ser, Cher Tian; Vestfrid, Jenya; Wu, Tony C. et al. (6 September 2022). "Autonomous Chemical Experiments: Challenges and Perspectives on Establishing a Self-Driving Lab" (in en). Accounts of Chemical Research 55 (17): 2454–2466. doi:10.1021/acs.accounts.2c00220. ISSN 0001-4842. PMC PMC9454899. PMID 35948428. https://pubs.acs.org/doi/10.1021/acs.accounts.2c00220.

- ↑ 17.0 17.1 Abolhasani, Milad; Kumacheva, Eugenia (30 January 2023). "The rise of self-driving labs in chemical and materials sciences" (in en). Nature Synthesis 2 (6): 483–492. doi:10.1038/s44160-022-00231-0. ISSN 2731-0582. https://www.nature.com/articles/s44160-022-00231-0.

- ↑ 18.0 18.1 Matsuda, Rieko; Ishibashi, Mumio; Takeda, Yasushi (1988). "Simplex optimization of reaction conditions with an automated system." (in en). Chemical and Pharmaceutical Bulletin 36 (9): 3512–3518. doi:10.1248/cpb.36.3512. ISSN 0009-2363. http://www.jstage.jst.go.jp/article/cpb1958/36/9/36_9_3512/_article.

- ↑ 19.0 19.1 Nikolaev, Pavel; Hooper, Daylond; Webber, Frederick; Rao, Rahul; Decker, Kevin; Krein, Michael; Poleski, Jason; Barto, Rick et al. (21 October 2016). "Autonomy in materials research: a case study in carbon nanotube growth" (in en). npj Computational Materials 2 (1): 16031. doi:10.1038/npjcompumats.2016.31. ISSN 2057-3960. https://www.nature.com/articles/npjcompumats201631.

- ↑ 20.0 20.1 Christensen, Melodie; Yunker, Lars P. E.; Adedeji, Folarin; Häse, Florian; Roch, Loïc M.; Gensch, Tobias; dos Passos Gomes, Gabriel; Zepel, Tara et al. (2 August 2021). "Data-science driven autonomous process optimization" (in en). Communications Chemistry 4 (1): 112. doi:10.1038/s42004-021-00550-x. ISSN 2399-3669. PMC PMC9814253. PMID 36697524. https://www.nature.com/articles/s42004-021-00550-x.

- ↑ 21.0 21.1 McMullen, Jonathan P.; Stone, Matthew T.; Buchwald, Stephen L.; Jensen, Klavs F. (17 September 2010). "An Integrated Microreactor System for Self-Optimization of a Heck Reaction: From Micro- to Mesoscale Flow Systems" (in en). Angewandte Chemie International Edition 49 (39): 7076–7080. doi:10.1002/anie.201002590. https://onlinelibrary.wiley.com/doi/10.1002/anie.201002590.

- ↑ 22.0 22.1 Sans, Victor; Porwol, Luzian; Dragone, Vincenza; Cronin, Leroy (2015). "A self optimizing synthetic organic reactor system using real-time in-line NMR spectroscopy" (in en). Chemical Science 6 (2): 1258–1264. doi:10.1039/C4SC03075C. ISSN 2041-6520. PMC PMC5811122. PMID 29560211. http://xlink.rsc.org/?DOI=C4SC03075C.

- ↑ 23.0 23.1 King, Ross D.; Rowland, Jem; Oliver, Stephen G.; Young, Michael; Aubrey, Wayne; Byrne, Emma; Liakata, Maria; Markham, Magdalena et al. (3 April 2009). "The Automation of Science" (in en). Science 324 (5923): 85–89. doi:10.1126/science.1165620. ISSN 0036-8075. https://www.science.org/doi/10.1126/science.1165620.

- ↑ 24.0 24.1 King, Ross D. (1 January 2011). "Rise of the Robo Scientists". Scientific American 304 (1): 72–77. doi:10.1038/scientificamerican0111-72. ISSN 0036-8733. https://www.scientificamerican.com/article/rise-of-the-robo-scientists.

- ↑ 25.0 25.1 25.2 Burger, Benjamin; Maffettone, Phillip M.; Gusev, Vladimir V.; Aitchison, Catherine M.; Bai, Yang; Wang, Xiaoyan; Li, Xiaobo; Alston, Ben M. et al. (9 July 2020). "A mobile robotic chemist" (in en). Nature 583 (7815): 237–241. doi:10.1038/s41586-020-2442-2. ISSN 0028-0836. https://www.nature.com/articles/s41586-020-2442-2.

- ↑ 26.0 26.1 MacLeod, B. P.; Parlane, F. G. L.; Morrissey, T. D.; Häse, F.; Roch, L. M.; Dettelbach, K. E.; Moreira, R.; Yunker, L. P. E. et al. (15 May 2020). "Self-driving laboratory for accelerated discovery of thin-film materials" (in en). Science Advances 6 (20): eaaz8867. doi:10.1126/sciadv.aaz8867. ISSN 2375-2548. PMC PMC7220369. PMID 32426501. https://www.science.org/doi/10.1126/sciadv.aaz8867.

- ↑ 27.0 27.1 Krishnadasan, S.; Brown, R. J. C.; deMello, A. J.; deMello, J. C. (2007). "Intelligent routes to the controlled synthesis of nanoparticles" (in en). Lab on a Chip 7 (11): 1434. doi:10.1039/b711412e. ISSN 1473-0197. http://xlink.rsc.org/?DOI=b711412e.

- ↑ 28.0 28.1 Tao, Huachen; Wu, Tianyi; Kheiri, Sina; Aldeghi, Matteo; Aspuru‐Guzik, Alán; Kumacheva, Eugenia (1 December 2021). "Self‐Driving Platform for Metal Nanoparticle Synthesis: Combining Microfluidics and Machine Learning" (in en). Advanced Functional Materials 31 (51): 2106725. doi:10.1002/adfm.202106725. ISSN 1616-301X. https://onlinelibrary.wiley.com/doi/10.1002/adfm.202106725.

- ↑ 29.0 29.1 Desai, Bimbisar; Dixon, Karen; Farrant, Elizabeth; Feng, Qixing; Gibson, Karl R.; van Hoorn, Willem P.; Mills, James; Morgan, Trevor et al. (11 April 2013). "Rapid Discovery of a Novel Series of Abl Kinase Inhibitors by Application of an Integrated Microfluidic Synthesis and Screening Platform" (in en). Journal of Medicinal Chemistry 56 (7): 3033–3047. doi:10.1021/jm400099d. ISSN 0022-2623. https://pubs.acs.org/doi/10.1021/jm400099d.

- ↑ 30.0 30.1 Dave, Adarsh; Mitchell, Jared; Kandasamy, Kirthevasan; Wang, Han; Burke, Sven; Paria, Biswajit; Póczos, Barnabás; Whitacre, Jay et al. (1 December 2020). "Autonomous Discovery of Battery Electrolytes with Robotic Experimentation and Machine Learning" (in en). Cell Reports Physical Science 1 (12): 100264. doi:10.1016/j.xcrp.2020.100264. https://linkinghub.elsevier.com/retrieve/pii/S2666386420302861.

- ↑ Winicov, H.; Schainbaum, J.; Buckley, J.; Longino, G.; Hill, J.; Berkoff, C.E. (1 December 1978). "Chemical process optimization by computer — a self-directed chemical synthesis system" (in en). Analytica Chimica Acta 103 (4): 469–476. doi:10.1016/S0003-2670(01)83110-X. https://linkinghub.elsevier.com/retrieve/pii/S000326700183110X.

- ↑ Chang, Jorge; Nikolaev, Pavel; Carpena-Núñez, Jennifer; Rao, Rahul; Decker, Kevin; Islam, Ahmad E.; Kim, Jiseob; Pitt, Mark A. et al. (3 June 2020). "Efficient Closed-loop Maximization of Carbon Nanotube Growth Rate using Bayesian Optimization" (in en). Scientific Reports 10 (1): 9040. doi:10.1038/s41598-020-64397-3. ISSN 2045-2322. PMC PMC7271124. PMID 32493911. https://www.nature.com/articles/s41598-020-64397-3.

- ↑ Roch, Loïc M.; Häse, Florian; Kreisbeck, Christoph; Tamayo-Mendoza, Teresa; Yunker, Lars P. E.; Hein, Jason E.; Aspuru-Guzik, Alán (20 June 2018). "ChemOS: Orchestrating autonomous experimentation" (in en). Science Robotics 3 (19): eaat5559. doi:10.1126/scirobotics.aat5559. ISSN 2470-9476. https://www.science.org/doi/10.1126/scirobotics.aat5559.

- ↑ Roch, Loïc M.; Häse, Florian; Kreisbeck, Christoph; Tamayo-Mendoza, Teresa; Yunker, Lars P. E.; Hein, Jason E.; Aspuru-Guzik, Alán (16 April 2020). Hu, Jianjun. ed. "ChemOS: An orchestration software to democratize autonomous discovery" (in en). PLOS ONE 15 (4): e0229862. doi:10.1371/journal.pone.0229862. ISSN 1932-6203. PMC PMC7161969. PMID 32298284. https://dx.plos.org/10.1371/journal.pone.0229862.

- ↑ Pollice, Robert; dos Passos Gomes, Gabriel; Aldeghi, Matteo; Hickman, Riley J.; Krenn, Mario; Lavigne, Cyrille; Lindner-D’Addario, Michael; Nigam, AkshatKumar et al. (16 February 2021). "Data-Driven Strategies for Accelerated Materials Design" (in en). Accounts of Chemical Research 54 (4): 849–860. doi:10.1021/acs.accounts.0c00785. ISSN 0001-4842. PMC PMC7893702. PMID 33528245. https://pubs.acs.org/doi/10.1021/acs.accounts.0c00785.

- ↑ Häse, Florian; Roch, Loïc M.; Kreisbeck, Christoph; Aspuru-Guzik, Alán (26 September 2018). "Phoenics: A Bayesian Optimizer for Chemistry" (in en). ACS Central Science 4 (9): 1134–1145. doi:10.1021/acscentsci.8b00307. ISSN 2374-7943. PMC PMC6161047. PMID 30276246. https://pubs.acs.org/doi/10.1021/acscentsci.8b00307.

- ↑ 37.0 37.1 Häse, Florian; Aldeghi, Matteo; Hickman, Riley J.; Roch, Loïc M.; Aspuru-Guzik, Alán (1 September 2021). "G ryffin : An algorithm for Bayesian optimization of categorical variables informed by expert knowledge" (in en). Applied Physics Reviews 8 (3): 031406. doi:10.1063/5.0048164. ISSN 1931-9401. https://pubs.aip.org/apr/article/8/3/031406/998861/Gryffin-An-algorithm-for-Bayesian-optimization-of.

- ↑ Reizman, Brandon J.; Wang, Yi-Ming; Buchwald, Stephen L.; Jensen, Klavs F. (2016). "Suzuki–Miyaura cross-coupling optimization enabled by automated feedback" (in en). Reaction Chemistry & Engineering 1 (6): 658–666. doi:10.1039/C6RE00153J. ISSN 2058-9883. PMC PMC5123644. PMID 27928513. http://xlink.rsc.org/?DOI=C6RE00153J.

- ↑ Baumgartner, Lorenz M.; Coley, Connor W.; Reizman, Brandon J.; Gao, Kevin W.; Jensen, Klavs F. (2018). "Optimum catalyst selection over continuous and discrete process variables with a single droplet microfluidic reaction platform" (in en). Reaction Chemistry & Engineering 3 (3): 301–311. doi:10.1039/C8RE00032H. ISSN 2058-9883. http://xlink.rsc.org/?DOI=C8RE00032H.

- ↑ Bédard, Anne-Catherine; Adamo, Andrea; Aroh, Kosi C.; Russell, M. Grace; Bedermann, Aaron A.; Torosian, Jeremy; Yue, Brian; Jensen, Klavs F. et al. (21 September 2018). "Reconfigurable system for automated optimization of diverse chemical reactions" (in en). Science 361 (6408): 1220–1225. doi:10.1126/science.aat0650. ISSN 0036-8075. https://www.science.org/doi/10.1126/science.aat0650.

- ↑ Granda, Jarosław M.; Donina, Liva; Dragone, Vincenza; Long, De-Liang; Cronin, Leroy (1 July 2018). "Controlling an organic synthesis robot with machine learning to search for new reactivity" (in en). Nature 559 (7714): 377–381. doi:10.1038/s41586-018-0307-8. ISSN 0028-0836. PMC PMC6223543. PMID 30022133. https://www.nature.com/articles/s41586-018-0307-8.

- ↑ Asche, Silke; Cooper, Geoffrey J. T.; Keenan, Graham; Mathis, Cole; Cronin, Leroy (10 June 2021). "A robotic prebiotic chemist probes long term reactions of complexifying mixtures" (in en). Nature Communications 12 (1): 3547. doi:10.1038/s41467-021-23828-z. ISSN 2041-1723. PMC PMC8192940. PMID 34112788. https://www.nature.com/articles/s41467-021-23828-z.

- ↑ Bornemann‐Pfeiffer, Martin; Wolf, Jakob; Meyer, Klas; Kern, Simon; Angelone, Davide; Leonov, Artem; Cronin, Leroy; Emmerling, Franziska (18 October 2021). "Standardization and Control of Grignard Reactions in a Universal Chemical Synthesis Machine using online NMR" (in en). Angewandte Chemie International Edition 60 (43): 23202–23206. doi:10.1002/anie.202106323. ISSN 1433-7851. PMC PMC8597166. PMID 34278673. https://onlinelibrary.wiley.com/doi/10.1002/anie.202106323.

- ↑ MacLeod, Benjamin P.; Parlane, Fraser G. L.; Rupnow, Connor C.; Dettelbach, Kevan E.; Elliott, Michael S.; Morrissey, Thomas D.; Haley, Ted H.; Proskurin, Oleksii et al. (22 February 2022). "A self-driving laboratory advances the Pareto front for material properties" (in en). Nature Communications 13 (1): 995. doi:10.1038/s41467-022-28580-6. ISSN 2041-1723. PMC PMC8863835. PMID 35194074. https://www.nature.com/articles/s41467-022-28580-6.

- ↑ Wu, Tony C; Aguilar‐Granda, Andrés; Hotta, Kazuhiro; Yazdani, Sahar Alasvand; Pollice, Robert; Vestfrid, Jenya; Hao, Han; Lavigne, Cyrille et al. (1 February 2023). "A Materials Acceleration Platform for Organic Laser Discovery" (in en). Advanced Materials 35 (6): 2207070. doi:10.1002/adma.202207070. ISSN 0935-9648. https://onlinelibrary.wiley.com/doi/10.1002/adma.202207070.

- ↑ Epps, Robert W.; Bowen, Michael S.; Volk, Amanda A.; Abdel‐Latif, Kameel; Han, Suyong; Reyes, Kristofer G.; Amassian, Aram; Abolhasani, Milad (1 July 2020). "Artificial Chemist: An Autonomous Quantum Dot Synthesis Bot" (in en). Advanced Materials 32 (30): 2001626. doi:10.1002/adma.202001626. ISSN 0935-9648. https://onlinelibrary.wiley.com/doi/10.1002/adma.202001626.

- ↑ Abdel-Latif, Kameel; Epps, Robert W.; Bateni, Fazel; Han, Suyong; Reyes, Kristofer G.; Abolhasani, Milad (1 February 2021). "Self‐Driven Multistep Quantum Dot Synthesis Enabled by Autonomous Robotic Experimentation in Flow" (in en). Advanced Intelligent Systems 3 (2): 2000245. doi:10.1002/aisy.202000245. ISSN 2640-4567. https://onlinelibrary.wiley.com/doi/10.1002/aisy.202000245.

- ↑ Mekki-Berrada, Flore; Ren, Zekun; Huang, Tan; Wong, Wai Kuan; Zheng, Fang; Xie, Jiaxun; Tian, Isaac Parker Siyu; Jayavelu, Senthilnath et al. (20 April 2021). "Two-step machine learning enables optimized nanoparticle synthesis" (in en). npj Computational Materials 7 (1): 55. doi:10.1038/s41524-021-00520-w. ISSN 2057-3960. https://www.nature.com/articles/s41524-021-00520-w.

- ↑ Li, Jiagen; Lu, Yihua; Xu, Yanheng; Liu, Chongfeng; Tu, Yuxiao; Ye, Shuqian; Liu, Haochen; Xie, Yi et al. (21 November 2018). "AIR-Chem: Authentic Intelligent Robotics for Chemistry" (in en). The Journal of Physical Chemistry A 122 (46): 9142–9148. doi:10.1021/acs.jpca.8b10680. ISSN 1089-5639. https://pubs.acs.org/doi/10.1021/acs.jpca.8b10680.

- ↑ Li, Jiagen; Li, Junzi; Liu, Rulin; Tu, Yuxiao; Li, Yiwen; Cheng, Jiaji; He, Tingchao; Zhu, Xi (27 April 2020). "Autonomous discovery of optically active chiral inorganic perovskite nanocrystals through an intelligent cloud lab" (in en). Nature Communications 11 (1): 2046. doi:10.1038/s41467-020-15728-5. ISSN 2041-1723. PMC PMC7184584. PMID 32341340. https://www.nature.com/articles/s41467-020-15728-5.

- ↑ von Drigalski, Felix; Tanaka, Kazutoshi; Hamaya, Masashi; Lee, Robert; Nakashima, Chisato; Shibata, Yoshiya; Ijiri, Yoshihisa (24 October 2020). "A Compact, Cable-driven, Activatable Soft Wrist with Six Degrees of Freedom for Assembly Tasks". 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (Las Vegas, NV, USA: IEEE): 8752–8757. doi:10.1109/IROS45743.2020.9341487. ISBN 978-1-7281-6212-6. https://ieeexplore.ieee.org/document/9341487/.

- ↑ Hamaya, Masashi; Lee, Robert; Tanaka, Kazutoshi; von Drigalski, Felix; Nakashima, Chisato; Shibata, Yoshiya; Ijiri, Yoshihisa (1 May 2020). "Learning Robotic Assembly Tasks with Lower Dimensional Systems by Leveraging Physical Softness and Environmental Constraints". 2020 IEEE International Conference on Robotics and Automation (ICRA) (Paris, France: IEEE): 7747–7753. doi:10.1109/ICRA40945.2020.9197327. ISBN 978-1-7281-7395-5. https://ieeexplore.ieee.org/document/9197327/.

- ↑ Ge, M.; Su, F.; Zhao, Z.; Su, D. (1 August 2020). "Deep learning analysis on microscopic imaging in materials science" (in en). Materials Today Nano 11: 100087. doi:10.1016/j.mtnano.2020.100087. https://linkinghub.elsevier.com/retrieve/pii/S258884202030016X.

- ↑ Suzuki, Yuta; Hino, Hideitsu; Kotsugi, Masato; Ono, Kanta (29 March 2019). "Automated estimation of materials parameter from X-ray absorption and electron energy-loss spectra with similarity measures" (in en). npj Computational Materials 5 (1): 39. doi:10.1038/s41524-019-0176-1. ISSN 2057-3960. https://www.nature.com/articles/s41524-019-0176-1.

- ↑ Tshitoyan, Vahe; Dagdelen, John; Weston, Leigh; Dunn, Alexander; Rong, Ziqin; Kononova, Olga; Persson, Kristin A.; Ceder, Gerbrand et al. (1 July 2019). "Unsupervised word embeddings capture latent knowledge from materials science literature" (in en). Nature 571 (7763): 95–98. doi:10.1038/s41586-019-1335-8. ISSN 0028-0836. https://www.nature.com/articles/s41586-019-1335-8.

- ↑ Abbott, Ryan (2016). "I Think, Therefore I Invent: Creative Computers and the Future of Patent Law" (in en). SSRN Electronic Journal. doi:10.2139/ssrn.2727884. ISSN 1556-5068. http://www.ssrn.com/abstract=2727884.

- ↑ Chen, A. (8 January 2020). "Can an AI be an inventor? Not yet.". MIT Technology Review. Massachusetts Institute of Technology. https://www.technologyreview.com/2020/01/08/102298/ai-inventor-patent-dabus-intellectual-property-uk-european-patent-office-law/. Retrieved 19 November 2022.

- ↑ 58.0 58.1 Carlson, Erika K. (1 November 2020). "Artificial Intelligence Can Invent But Not Patent—For Now" (in en). Engineering 6 (11): 1212–1213. doi:10.1016/j.eng.2020.09.003. https://linkinghub.elsevier.com/retrieve/pii/S209580992030254X.

- ↑ 59.0 59.1 Abbott, R.; Austin, R.; Davidson, J.R. et al. (2022). "The Artificial Inventor Project". https://artificialinventor.com/. Retrieved 19 November 2022.

- ↑ DABUS (2021). "ZA 2021/03242 - Food Container and Devices and Methods for Attracting Enhanced Attention" (PDF). Patent Journal 54 (7): 255. ISSN 2223-4837. https://iponline.cipc.co.za/Publications/PublishedJournals/E_Journal_July%202021%20Part%202.pdf.

- ↑ "Commissioner of Patents v Thaler [2022 FCAFC 62"]. Federal Court of Australia. 13 April 2022. https://www.judgments.fedcourt.gov.au/judgments/Judgments/fca/full/2022/2022fcafc0062. Retrieved 19 November 2022.

- ↑ "AI cannot be named as inventor on patent applications". European Patent Office. 21 December 2021. https://www.epo.org/news-events/news/2021/20211221.html. Retrieved 19 November 2022.

- ↑ "発明者等の表示について". Japan Patent Office. 30 July 2021. https://www.jpo.go.jp/system/process/shutugan/hatsumei.html. Retrieved 19 November 2022.

- ↑ "日本における発明者の決定" (PDF). Japan Patent Office. https://www.jpo.go.jp/resources/shingikai/sangyo-kouzou/shousai/tokkyo_shoi/document/seisakubukai-06-shiryou/paper07_1.pdf. Retrieved 19 November 2022.

- ↑ Kageyama, K. (1 October 2010). "Formation of invention/joint invention and recognition of inventor/joint inventor" (in en). Journal of Intellectual Property Law & Practice 5 (10): 699–712. doi:10.1093/jiplp/jpq097. ISSN 1747-1532. https://academic.oup.com/jiplp/article-lookup/doi/10.1093/jiplp/jpq097.

- ↑ "Section 2 - Inventive Step" (PDF). Japan Patent Office. https://www.jpo.go.jp/e/system/laws/rule/guideline/patent/tukujitu_kijun/document/index/03_0202_e.pdf. Retrieved 19 November 2022.

- ↑ Nakayama, I. (2019). "AI and Inventive Step – Proposal of Issues". Patent 72 (12): 179–99.

- ↑ Abbott, Ryan (2017). "Everything is Obvious" (in en). SSRN Electronic Journal. doi:10.2139/ssrn.3056915. ISSN 1556-5068. https://www.ssrn.com/abstract=3056915.

- ↑ "Artificial Intelligence Collides with Patent Law". World Economic Forum. 20 April 2018. https://www.weforum.org/whitepapers/artificial-intelligence-collides-with-patent-law. Retrieved 19 November 2022.

- ↑ "CCIA Comments on WIPO draft issues paper on IP and AI" (PDF). Computer & Communications Industry Association. 14 February 2020. https://www.wipo.int/export/sites/www/about-ip/en/artificial_intelligence/call_for_comments/pdf/org_ccia.pdf. Retrieved 19 November 2022.

- ↑ Ramalho, Ana (2018). "Patentability of AI-Generated Inventions: Is a Reform of the Patent System Needed?" (in en). SSRN Electronic Journal. doi:10.2139/ssrn.3168703. ISSN 1556-5068. https://www.ssrn.com/abstract=3168703.

- ↑ COPE Discussion Document: Authorship. 1 June 2014. doi:10.24318/cope.2019.3.3. https://publicationethics.org/node/34946.

- ↑ "Defining the Role of Authors and Contributors". International Committee of Medical Journal Editors. http://www.icmje.org/recommendations/browse/roles-and-responsibilities/defining-the-role-of-authors-and-contributors.html. Retrieved 19 November 2022.

- ↑ Generative Pre-trained Transformer, ChatGPT; Zhavoronkov, Alex (21 December 2022). "Rapamycin in the context of Pascal’s Wager: generative pre-trained transformer perspective" (in en). Oncoscience 9: 82–84. doi:10.18632/oncoscience.571. ISSN 2331-4737. PMC PMC9796173. PMID 36589923. https://www.oncoscience.us/lookup/doi/10.18632/oncoscience.571.

- ↑ O’Connor, Siobhan; ChatGPT (1 January 2023). "Open artificial intelligence platforms in nursing education: Tools for academic progress or abuse?" (in en). Nurse Education in Practice 66: 103537. doi:10.1016/j.nepr.2022.103537. https://linkinghub.elsevier.com/retrieve/pii/S1471595322002517.

- ↑ Stokel-Walker, Chris (26 January 2023). "ChatGPT listed as author on research papers: many scientists disapprove" (in en). Nature 613 (7945): 620–621. doi:10.1038/d41586-023-00107-z. ISSN 0028-0836. https://www.nature.com/articles/d41586-023-00107-z.

- ↑ Parviainen, Jaana; Coeckelbergh, Mark (1 September 2021). "The political choreography of the Sophia robot: beyond robot rights and citizenship to political performances for the social robotics market" (in en). AI & SOCIETY 36 (3): 715–724. doi:10.1007/s00146-020-01104-w. ISSN 0951-5666. https://link.springer.com/10.1007/s00146-020-01104-w.

- ↑ "Recommendation of the Council on Artificial Intelligence". OECD Legal Instruments. OECD. 21 May 2019. https://legalinstruments.oecd.org/en/instruments/OECD-LEGAL-0449. Retrieved 19 November 2022.

Notes

This presentation is faithful to the original, with only a few minor changes to presentation. In some cases important information was missing from the references, and that information was added. In the original, there are multiple instances of citing research work using the last name of the last author listed, rather than the last name of the first author listed; this may have been a product of Japanese culture tending to read text from right to left. For this version, the last name of the first author was used to be consistent with research norms.